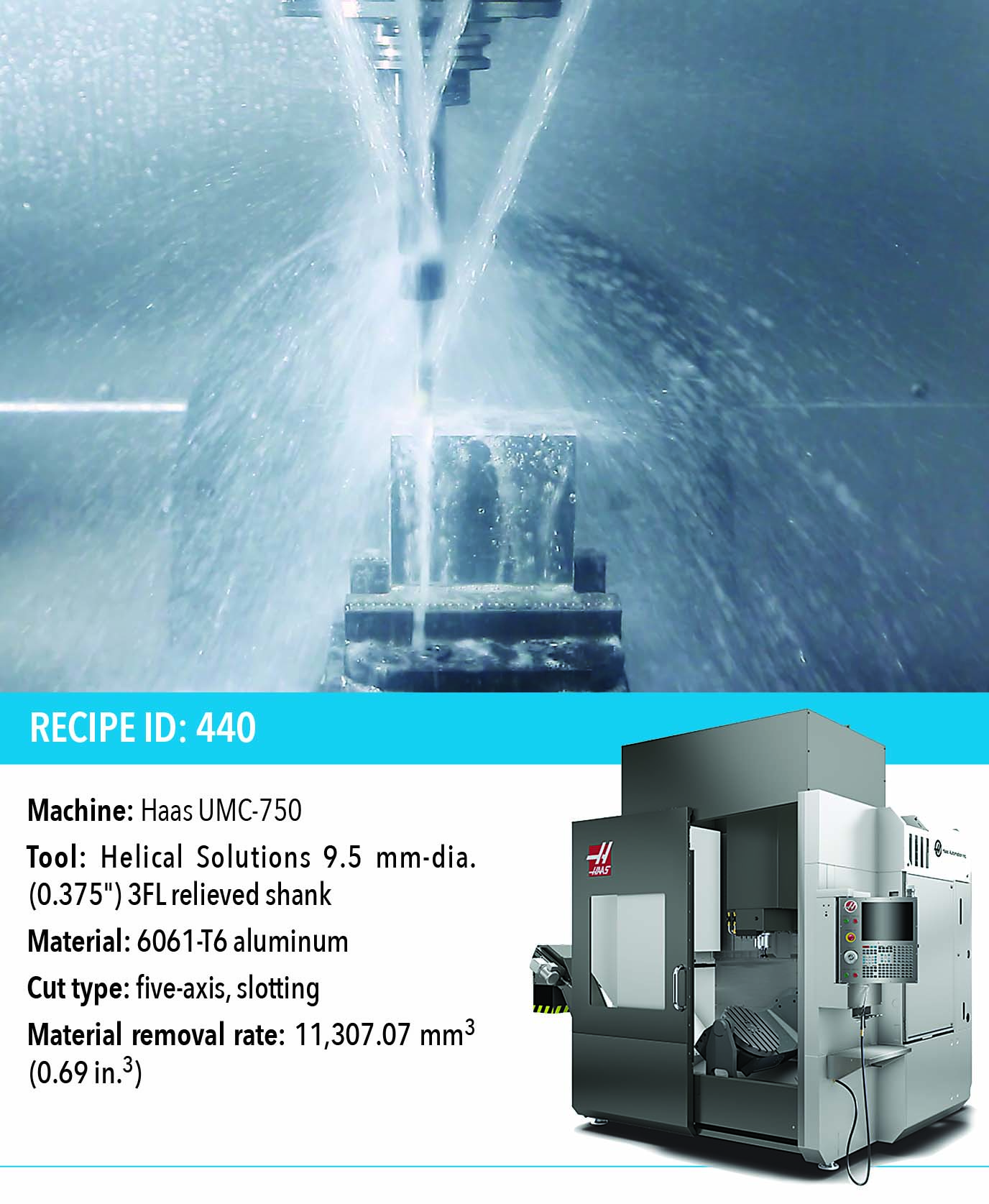

Presented here is ProvenCut recipe 440 for machining a deep slot in 6061-T6 aluminum. ProvenCut recipes, which use real-world, unbiased testing to enable successful cutting, have been developed at our machine shop since last year.

With 63.5 mm (2.5") of the 9.5 mm-dia. (0.375") endmill from Helical Solutions LLC sticking out from the collet holder face, or 6.7 times the tool diameter, determining this recipe was sure to be tricky — and a recipe that ultimately deviated significantly from the toolmaker’s recommended speeds and feeds. Even Helical Solutions’ software for calculating speeds and feeds, Machining Advisor Pro, suggested running the machine at its maximum spindle speed.

While carbide cutting tools frequently can exceed a cutting speed of 304.8 m/min. (1,000 sfm) when machining a nonferrous material, a recipe that includes a long gauge length and stick-out would not support such a high speed. Although speed and feed calculators often recommend starting points, that software is unable to account for all cutting conditions. As this example illustrates, the initial recommendations were unsatisfactory.

The task required milling a deep slot in which chatter would lead to an unacceptable surface finish, re-cutting of chips and likely a scrapped part. Machinists commonly do not have the time, material or machine setup to start testing a new recipe; their goal is to machine a part as quickly as possible while having confidence in the process. Machinists do not want suggestions but solutions — things that work on the first try. For this recipe, surface speed was reduced to 61 m/min. (200 sfm) at a feed rate of 0.0381 mm (0.0015") per tooth and 233.7 mm/min. (9.2 ipm) to provide a stable, reliable cut that was free of chatter.

This is how ProvenCut offers substantial value to any machine shop owner, machinist or CAM programmer. With ProvenCut, there are no formulas working behind the scenes to calculate theoretical recipes, no surprise factors — like extreme stick-out — to invalidate calculations and no guesswork. ProvenCut helps shops produce good parts without trial and error.

To view a video of the slotting operation at www.ctemag.com enter this URL on your web browser: cteplus.delivr.com/2t5vn

Related Glossary Terms

- chatter

chatter

Condition of vibration involving the machine, workpiece and cutting tool. Once this condition arises, it is often self-sustaining until the problem is corrected. Chatter can be identified when lines or grooves appear at regular intervals in the workpiece. These lines or grooves are caused by the teeth of the cutter as they vibrate in and out of the workpiece and their spacing depends on the frequency of vibration.

- collet

collet

Flexible-sided device that secures a tool or workpiece. Similar in function to a chuck, but can accommodate only a narrow size range. Typically provides greater gripping force and precision than a chuck. See chuck.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- cutting speed

cutting speed

Tangential velocity on the surface of the tool or workpiece at the cutting interface. The formula for cutting speed (sfm) is tool diameter 5 0.26 5 spindle speed (rpm). The formula for feed per tooth (fpt) is table feed (ipm)/number of flutes/spindle speed (rpm). The formula for spindle speed (rpm) is cutting speed (sfm) 5 3.82/tool diameter. The formula for table feed (ipm) is feed per tooth (ftp) 5 number of tool flutes 5 spindle speed (rpm).

- endmill

endmill

Milling cutter held by its shank that cuts on its periphery and, if so configured, on its free end. Takes a variety of shapes (single- and double-end, roughing, ballnose and cup-end) and sizes (stub, medium, long and extra-long). Also comes with differing numbers of flutes.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- slotting

slotting

Machining, normally milling, that creates slots, grooves and similar recesses in workpieces, including T-slots and dovetails.

- web

web

On a rotating tool, the portion of the tool body that joins the lands. Web is thicker at the shank end, relative to the point end, providing maximum torsional strength.

ARTICLES

ARTICLES