Boring Tools

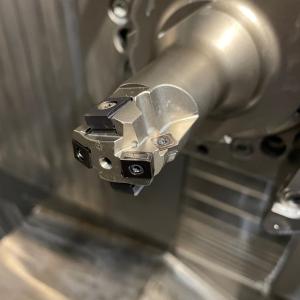

CTE Booth Visit with Horn USA @ Eastec

Horn USA's Adrian Noonan, technical specialist, tours kiosk after kiosk at the Horn booth during Eastec 2023, highlighting the newest innovations for broaching, narrow width slot milling cutters, form boring and internal grooving.

CTE Booth Visit with CERATIZIT USA @ Eastec

CERATIZIT USA's Chuck Somerville, sales engineer for cutting tools, provides a table by table overview of the company's cutting tools displayed at its booth during Eastec 2023.

Rigibore's Zenith ActiveEdge adjusts automatically

Rigibore’s Zenith ActiveEdge adjusts automatically from your measurement data, ensuring perfect bores with zero downtime. ActiveEdge tools are micron accurate in diameter (0.001) (0.00004") so even the tightest of tolerances can be met effortlessly. Save money by increasing production and eliminating scrap, with ActiveEdge technology.

Boring with in-process gauging

Posted as a supplement to "The Zenith of Boring," a feature article appearing in the July 2022 issue of Cutting Tool Engineering magazine, this video demonstrates how Rigibore's Zenith system integrates ActiveEdge tools with in-process gauging to enable a machine controller to automatically compensate for insert wear, temperature changes and material inconsistency without manual intervention and without manufacturing interruptions.