Throughout the sometimes-contentious world of machining, the debate rages about whether to apply flood coolant or cut dry. As in many areas of machining, the choice is not easy and requires careful and informed consideration. To further complicate the decision, minimum-quantity lubrication (MQL) can be a successful compromise that provides an efficient and effective answer to the troublesome question.

Wet Coolant

Cooling mixture, cutting lubricant, cutting fluid and coolant are common terms that refer to a liquid applied for both cooling and lubricating the tool/workpiece interface while machining.

All cutting generates unwelcome friction at that interface. The presence of coolant ensures that the friction between the two surfaces is reduced and lubrication significantly enhances the metal-removal process.

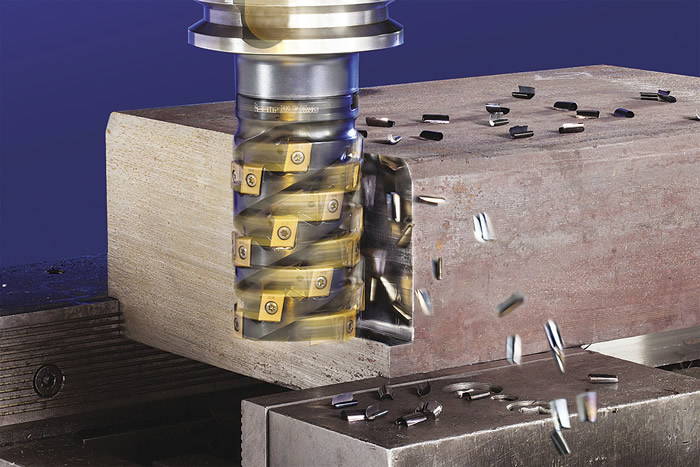

Flood coolant is not recommended for roughing steel with an extended-flute milling cutter. All images courtesy Iscar Metals.

During machining, the temperature in the cutting zone becomes extremely high, which depends on factors like the workpiece material, cutting data and cutting tool substrate. For example, the temperature for a tungsten-carbide tool at the point of contact between a cutting edge and the workpiece is estimated at 1,100° to 1,200° C (2,012° to 2,192° F).

The application of coolant lowers the cutting zone temperature and reduces the thermal load on the tool. In addition, coolant improves chip evacuation and also reduces the concentration of metal dust. Therefore, the coolant supply is directly connected to several important benefits. Specifically, coolant:

■ advances process performance by improving machining accuracy and surface finish;

■ increases profits by raising productivity and extending tool life; and

■ augments environmental control.

When interrupted milling, the cutting edge of the tool experiences a cyclic thermal load because the ambient temperature dramatically changes as the edge enters and then exits the cut. This exposes a tool’s cutting edge to severe heat stress—comparable to repeated thermal shock.

Cemented carbide is a sintered, powder metallurgy product and is sensitive to thermal shock loads, which destroy cutting edges. When using a carbide tool, coolant application may increase the “shock treatment” and unintentionally contribute to cutting edge failure. Extreme temperatures result in plastic deformation of the cutting edge, while the temperature difference leads to thermal cracks. This becomes even more exaggerated in situations that generate a high level of heat, such as when milling difficult-to-cut materials. Although wet machining provides multiple benefits, it certainly can be problematic when milling.

In many cases, however, having an efficient coolant supply is not only reasonable but absolutely necessary to ensure productive milling. For example, when machining titanium and heat-resistant superalloys, austenitic and duplex (austenitic-ferritic) stainless steels—or even special-purpose, hardened, alloyed cast iron—a considerable amount of friction and heat is generated. The flushing effect of coolant also significantly enhances chip evacuation and reduces recutting of chips, particularly when milling deep pockets or narrow slots.

Iscar’s Multi-Master ballnose milling head is intended for machining difficult-to-cut materials and has channels to supply coolant where it is needed.

Compared with traditional low-pressure coolant, normally delivered at around 20 bar (290 psi), high-pressure coolant (HPC) delivered at about 80 bar (1,160 psi) and ultrahigh-pressure coolant delivered at 350 bar (5,000 psi) are welcome developments.

When applying traditional low-pressure coolant, the high level of heat produces a vapor film in the cutting zone that intensifies heat transfer. However, a high-pressure jet that directly targets the cutting zone effectively penetrates this film and gets coolant into the cut. It also improves the cutting action by changing the shear-plane angle and creating thin, manageable chips. Taking advantage of HPC is only possible when using an appropriate machine tool or by retrofitting an existing machine.

Dry Machining, Other Options

Ignoring cases where the use of cutting fluid is essential, machine operators will appreciate the elimination of coolant and the resulting productivity improvements.

As previously noted, roughing generates extremely high levels of heat, and coolant may be destructive because of the critical thermal stress it causes. In contrast, the temperature of the insert’s cutting edge will remain high when dry roughing, but not overly high if the machining parameters are set correctly. For example, the tool temperature will vary within a relatively narrow range, such as 300° to 700° C (572° to 1,292° F), that will not lead to thermal shock.

The T490 extended-flute cutter from Iscar can delivery high-pressure coolant.

As for light cuts when high-speed machining, especially for workpieces 45 HRC or harder, cooling by air is strongly recommended. The absence of wet coolant in this situation will considerably increase tool life.

Other important factors to consider are cooling economy and work safety. If cutting tool investment in batch production is estimated at 3 percent of total part cost, the share connected with liquid coolant, such as purchasing, maintenance and filtration, can be 16 to 17 percent.

Also, prolonged exposure to coolant by operating personnel may cause health problems. Many national and international standards, as well as published advice for worker safety and environmental control, spell out increasingly stringent guidelines related to cutting fluid exposure, containment and disposal.

Without cutting fluid, there is no need for a coolant pump, a coolant recycling system and other expensive machine tool accessories, further reducing total costs.

When near-dry milling with MQL, the tool’s cutting edge works inside a mist formed from oil and compressed air, which is sprayed directly into the cutting zone. Depending on the design of a machine tool and milling cutter, the mist is delivered externally or internally through the cutter. The main function of MQL is to lubricate the cutting edge. As a result, the machining process consumes only the necessary quantity of oil, and, therefore, the lubrication is more efficient.

In addition, the machined workpiece and chips are nearly dry, making part cleaning and chip disposal much easier and quicker. MQL also increases tool life, and the working area of the machine tool remains relatively dry, enabling various machine tool components to perform better and last longer.

Another coolant option is cryogenic machining. Applied at extremely low temperatures, cryogenic machining drastically reduces the possibility of overheating a part and extends tool life. Combining this principle with MQL results in a more-effective, minimum-quantity cryogenic machining method, because the coolant, such as liquid nitrogen, is supplied directly to the cutting zone via the tool.

Alternatively, some processes deliver CO2 under pressure to the cutting zone. In each of these methods, the particles of cryogenic coolant vaporize from the tool edge and, in doing so, remove heat. However, cryogenic cooling is not a cheap method and requires a specially designed machine tool.

The Tool

Whether to machine dry or wet will always depend on the specific application and available machine tool. Nevertheless, the manufacturers of cutting tools take into account customer requirements and provide tools that will ensure productive machining regardless of the cooling method.

The vast majority of indexable-insert mills have internal coolant channels. This allows coolant to be effectively directed into the cutting zone. For facemills without coolant channels, Iscar Metals proposes a clamping screw with an adjustable nozzle. In many cases, it not only improves coolant supply but enhances chip evacuation.

When exploring milling cutters for high-pressure coolant and cryogenic machining, the body of the cutter should be designed accordingly. The shape of the internal channels, their size and sealing elements, if necessary, should ensure the optimal flow of coolant without any disturbance. The most important elements are the nozzles that are mounted in the channel outlets, because they optimize the impact of the high-velocity coolant jet and direct it exactly to where it is needed.

Last but not least, consider the indexable carbide insert itself. Although the insert’s edge performs the cutting, how does it relate to the coolant method? The key to understanding this relationship is the carbide grade and, more specifically, the coating. The coating provides a barrier for heat penetration and must be resistant to destructive thermal shock.

Understandably, there is no universal coating equally suitable for productive wet and dry machining. Indexable carbide inserts are available with coatings to suit all applications. Some are more effective for wet machining while others provide advantages when dry machining.

The discussion about how much coolant to apply and at what pressure will continue, but the tools and technology are available for all scenarios to achieve a level of productivity that might leave machinists a little teary-eyed with joy.

Contact Details

Related Glossary Terms

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- cutting fluid

cutting fluid

Liquid used to improve workpiece machinability, enhance tool life, flush out chips and machining debris, and cool the workpiece and tool. Three basic types are: straight oils; soluble oils, which emulsify in water; and synthetic fluids, which are water-based chemical solutions having no oil. See coolant; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- lapping compound( powder)

lapping compound( powder)

Light, abrasive material used for finishing a surface.

- metalcutting ( material cutting)

metalcutting ( material cutting)

Any machining process used to part metal or other material or give a workpiece a new configuration. Conventionally applies to machining operations in which a cutting tool mechanically removes material in the form of chips; applies to any process in which metal or material is removed to create new shapes. See metalforming.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling cutter

milling cutter

Loosely, any milling tool. Horizontal cutters take the form of plain milling cutters, plain spiral-tooth cutters, helical cutters, side-milling cutters, staggered-tooth side-milling cutters, facemilling cutters, angular cutters, double-angle cutters, convex and concave form-milling cutters, straddle-sprocket cutters, spur-gear cutters, corner-rounding cutters and slitting saws. Vertical cutters use shank-mounted cutting tools, including endmills, T-slot cutters, Woodruff keyseat cutters and dovetail cutters; these may also be used on horizontal mills. See milling.

- minimum-quantity lubrication

minimum-quantity lubrication

Use of cutting fluids of only a minute amount—typically at a flow rate of 50 to 500 ml/hr.—which is about three to four orders of magnitude lower than the amount commonly used in flood cooling. The concept addresses the issues of environmental intrusiveness and occupational hazards associated with the airborne cutting fluid particles on factory shop floors. The minimization of cutting fluid also saves lubricant costs and the cleaning cycle time for workpieces, tooling and machines. Sometimes referred to as “near-dry lubrication” or “microlubrication.”

- plastic deformation

plastic deformation

Permanent (inelastic) distortion of metals under applied stresses that strain the material beyond its elastic limit.

- powder metallurgy

powder metallurgy

Processes in which metallic particles are fused under various combinations of heat and pressure to create solid metals.

- stainless steels

stainless steels

Stainless steels possess high strength, heat resistance, excellent workability and erosion resistance. Four general classes have been developed to cover a range of mechanical and physical properties for particular applications. The four classes are: the austenitic types of the chromium-nickel-manganese 200 series and the chromium-nickel 300 series; the martensitic types of the chromium, hardenable 400 series; the chromium, nonhardenable 400-series ferritic types; and the precipitation-hardening type of chromium-nickel alloys with additional elements that are hardenable by solution treating and aging.

- superalloys

superalloys

Tough, difficult-to-machine alloys; includes Hastelloy, Inconel and Monel. Many are nickel-base metals.