Contact Details

Contact Details

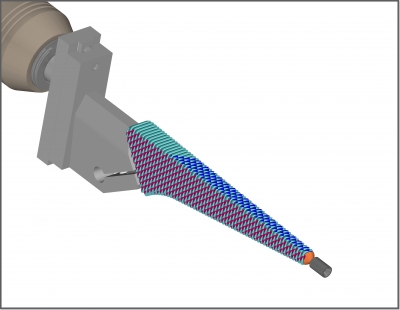

Star Cutter Company and Hexagon Manufacturing Intelligence have established a partnership that enables the Star Cutter NXT 5-axis grinders to be sold with a seat of pre-loaded ESPRIT CAM software. This packaged solution is aimed at assisting manufacturers of complex medical tooling, such as hip rasps, rotary files, bone files and drills, etc. Having certified ESPRIT post processors on the NXT ensures faster launch and error-free program code every time.

“ESPRIT’s proven ability in easing the programming and production of intricate parts makes it a perfect partner for optimizing the performance of our NXT grinding machines,” said Brad Lawton, Star Cutter Chairman and CEO. “We are confident this arrangement will help our customers, while also providing new business opportunity for both companies.”

“This is our first formalized partnership with a grinding company,” said ESPRIT’s Midwest Operations Manager Vytas Cijunelis, “And Star Cutter was the right choice for us given the NXT’s grinding capability and their team’s process knowledge in producing medical tooling. We look forward to expanding our footprint in this market.”

The NXT grinder is a versatile 5-axis CNC machine with a small footprint, large grind zone and a modular design that quickly adapts to demanding application requirements. ESPRIT uses a digital twin of the manufacturing envelope to simplify the programming process and deliver edit-free G-code. Customers that already have ESPRIT can add the Star Cutter NXT’s digital machine package to their existing license and program the NXT using the software they already own.

Star Cutter will feature an NXT running ESPRIT software for demonstration at its Elk Rapids, Mich. facility. Video and remote demonstrations are also available.

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- modular design ( modular construction)

modular design ( modular construction)

Manufacturing of a product in subassemblies that permits fast and simple replacement of defective assemblies and tailoring of the product for different purposes. See interchangeable parts.