‘Rosie’ and women in manufacturing—a reader responds

‘Rosie’ and women in manufacturing—a reader responds

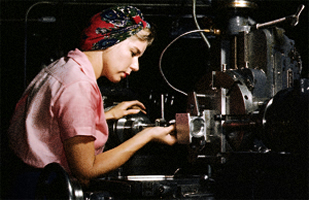

Last week's blog post on the successors of Rosie the Riveter inspired a reader to share her own experience as an early woman in manufacturing. Lois Anderson was tasked with walking into plants in Southwestern Michigan to convince dubious managers and workers to use new methods to improve their production quality and efficiency. In the end, she helped them excel.

My blog post on Industry's call for modern Rosies-the-Riveters (Oct. 27: Manufacturers to women: 'Daughters of Rosie, we need you!') inspired a response from Lois Anderson (no relation), who overcame male distrust to get companies in Michigan to, well, Excel. Lois writes:

I read your article with great respect for the women represented by Rosie the Riveter, and great joy for those of us who continued the fight to be included and respected by our male counterparts.

For many years I was the corporate training manager for Dexter Axle. Prior to that I taught for Southwestern Michigan College in their College at Work program. That program saw me going from plant to plant and teaching courses such as "Introduction to Computers" and "Quality Assurance," using Microsoft Excel as a tool to improve efficiencies at companies in Paw Paw, Berrien Springs, Niles, and many other places.

When I first suggested to some supervisors at a tool & die company in Berrien Springs that they could improve their workflow and quality by using Excel to track which dies would run the best on which machines--the supervisors rolled their eyes at me. I could hear them thinking, "What does this woman know about our processes?"

The superintendent of the plant had a different take. "Dr. Lois," he asked, "how did you know that?"

I explained how in every manufacturing process there are quality-assurance methods that not only improve quality, they also improve efficiency and effectiveness (to borrow from Edwards Deming and Peter Drucker).

The supervisor responded that they just cannot afford to take the time to put certain dies on certain machines. I replied, "You cannot afford not to take the time to put certain dies on certain machines." As he learned to use Excel for tracking the efficiency of usage, I made a convert. Me—this little 5-ft. woman, made a convert of a plant superintendent with decades of experience.

Once the plant superintendent was onboard with the process of tracking quality along with efficiency of usage—the rest was history. I became accepted by everyone in the plant as an expert who could be counted on to provide training and ideas that would make the company more profitable. The plant manager, who initially was not happy with this mere woman sent out by a college, became a convert as well.

Yes, women in manufacturing are here to stay.

Lois Anderson, Proud Daughter of Rosie

Lois added a PS: "I am retired and now use many metalworking techniques to create jewelry. Guess what? Different dies still perform differently in my hydraulic press and rolling mill."