Machining titanium today and tomorrow

Machining titanium today and tomorrow

Without a doubt, cutting tools for machining titanium must be well-engineered. This was reinforced for me while attending Horn Technology Days 2017 May 10 to 12 at Hartmetall-Werkzeugfabrik Paul Horn GmbH's in Tübingen, Germany.

Without a doubt, cutting tools for machining titanium must be well-engineered. This was reinforced for me while attending Horn Technology Days 2017 May 10 to 12 at Hartmetall-Werkzeugfabrik Paul Horn GmbH's in Tübingen, Germany.

The event featured eight presentations about the toolmaker's technological developments. In addition, the 3,000-plus attendees could tour several production facilities, in which Horn has invested more than $76 million during the previous year. The event's motto was "A glimpse into the future" and, as board member Andreas Vollmer emphasized during a press conference, the company believes in the future.

Vollmer pointed out that machining titanium is becoming a bigger topic at Horn. This is primarily because of a fivefold increase in the consumption of titanium worldwide during the past 20 years to a current level of around 330,000 tons, according to the company. However, there are drawbacks that must be overcome when machining titanium. For example, it is susceptible to the detrimental effect of strain hardening when being cut, and sharp cutting edges, correct machining parameters and optimal chip formation are essential. Also, the hardness of the tools and the heat resistance of their coatings must be appropriate because the metal is such a poor conductor of heat.

In a presentation titled "Economical titanium machining with high-feed milling cutters," Chris Smith, applications engineer at U.K.-based Horn Cutting Tools Ltd., said half of all titanium parts are made of the Ti6Al4V alloy, which is almost as light as aluminum yet stronger than steel. Unfortunately, titanium is significantly more expensive than both metals—as much as 200 times the price of crude steel, the company reports.

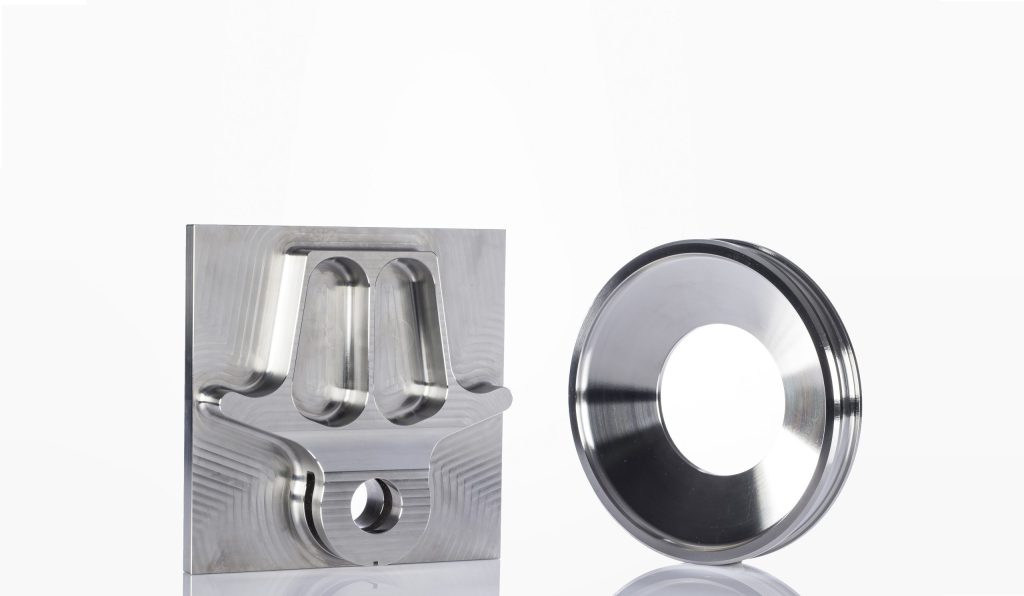

He described two projects to boost the efficiency of machining titanium and, therefore, lower the cost per part. In the multiple-company "Heavy Metal" project that Horn participated in, the goal was to at least double the metal-removal rate or halve the production time when cutting titanium. Horn has spent several years optimizing tools for milling titanium, which has included finding the right coating, polishing the cutting edges and enhancing the clearance, helix and relief angles. The result is the DS Titan line of endmills.

The other project is being conducted at the German university PTW TU Darmstadt and involves "hybrid" machining. Smith explained that an inductor travels ahead of the cutting tool and heats the titanium workpiece to 150° to 200° C (302° to 392° F) before it is cut. CO2 is applied to cool the tool/workpiece interface.

Smith added that there is no negative impact on the structural surface of titanium as a result of being heated, and the university will continue its experiments throughout the rest of the year. Conclusive results are not yet available, but "the initial results show a better material-removal rate," he said. "We'll see how it develops."