Software speeds indexable and special insert grinding

Software speeds indexable and special insert grinding

InsertsPRO, ANCA's new special inserts grinding package, supports ISO-standard inserts sourced from global catalogues for any milling or turning machine —as well as customer-specific special inserts developed for optimized applications, all on a seamless, automated platform.

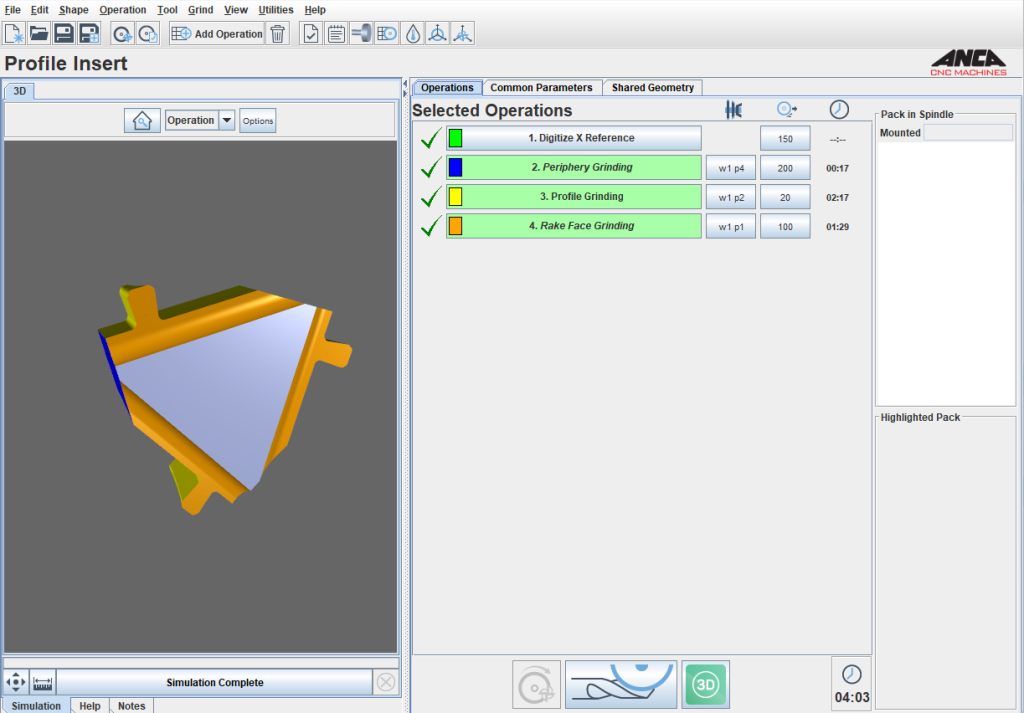

InsertsPRO, ANCA's new special inserts grinding package, supports ISO-standard inserts sourced from global catalogues for any milling or turning machine —as well as customer-specific special inserts developed for optimized applications, all on a seamless, automated platform. Designed to deliver flexibility, speed, and premium-quality output, InsertsPRO is the smart choice for toolmakers looking to reduce costs, optimize cycle times, and future-proof production.

The company says that InsertsPRO delivers faster setup and changeovers through automation and smart workflows, reduced operator intervention and downtime for greater productivity, lower production costs with optimized grinding strategies, advanced simulation for first time-right production and fewer scrap parts, and seamless integration into existing ANCA ToolRoom RN35 workflows.

InsertsPRO is fully integrated into ANCA's ToolRoom RN35 software, and existing ToolRoom users can upgrade to a suite of features:

- Advanced Simulation Tools – High-resolution 3D visuals, grinding path simulation, and integrated measurement

- Flexible Profile & Rake Face Design – Profile editor or DXF overlay with precise lead-in/out control

- Multiple Cutting-Edge Support – Uniform edge geometry with automated X-axis rotation

- Flexibility in Clamping Orientation – Fast changeovers with advanced transformation

- Optimized Relief & Rake Grinding – Wide range of styles, wheel types, and compensation options

- CIM3D Integration – Process validation, collision detection, and optimization for first time-right production.