AI solution accelerates CAM programming

AI solution accelerates CAM programming

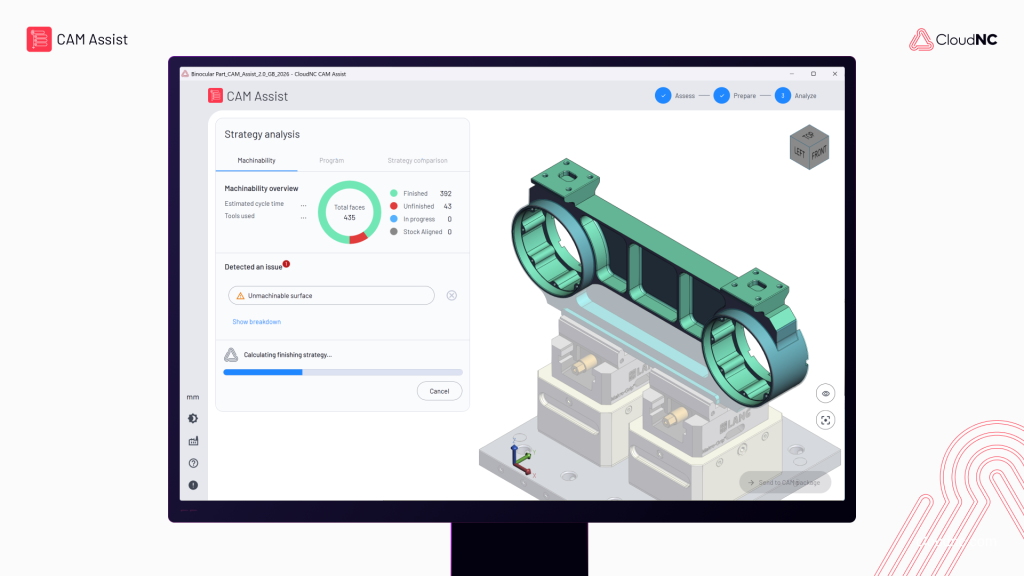

CAM Assist 2.0 from CloudNC takes a CAD model to machine-ready toolpaths. The company said that CAM Assist 2.0 retains the speed of the original CAM Assist, while adding the oversight, feedback and shared intelligence elements that machine shops need to use AI with confidence.

CAM Assist 2.0 from CloudNC takes a CAD model to machine-ready toolpaths. The company said that CAM Assist 2.0 retains the speed of the original CAM Assist, while adding the oversight, feedback and shared intelligence elements that machine shops need to use AI with confidence.

Programmers using CAM Assist can now stay firmly in control of every critical decision, while still saving hours as they turn CAD models into reliable toolpaths. The company added that the new 2.0 upgrade shows that AI and human expertise can work side by side, improving a machinist's productivity even further.

CAM Assist 2.0 is a web-based CAM automation application that initiates from the user's CAM package. 3-axis and 3+2 operations are supported. In the new web UI, the user still generates a working toolpath by pressing the CAM Assist button. Now, CAM Assist 2.0 breaks out the AI stages so that parts can be assessed prior to running. Moreover, as files are being computed, control over strategy editing is passed to the user.

What's new and better in CAM Assist 2.0:

- One-click configuration – Intelligent defaults and a configuration workflow let machinists start programming in minutes

- AI guidance at every step – Context-aware recommendations - shaped by part geometry, machine constraints and tools and fixtures - appear precisely when choosing strategies, tool assemblies or feeds and speeds, increasing feedback

- Human-in-the-loop oversight – Before any toolpath is committed to a CAM system, CAM Assist enables review, letting users inspect, adjust and edit each strategy operation so shop standards are never compromised.

- Seamless hand-off – Once approved, the strategies are pushed directly back into the user's preferred CAM package, ready for code generation and verification

CAM Assist 2.0 also makes machine, material, and tool assembly management easy, as it is tailored to the user's shop environment and configures itself to the customer.

With cloud-storage of these elements, CAM Assist can run faster, utilize more extensive tool libraries and parameters, and serve as a common source between CAM programmers. This helps standardize output and achieve consistent results across a machine shop's output.

CloudNC will make CAM Assist 2.0 available to all customers across Autodesk Fusion, Mastercam and Siemens NX platforms. The company expects to announce future integrations.