Tungaloy expands PVD Grade for broader milling spplications

Tungaloy expands PVD Grade for broader milling spplications

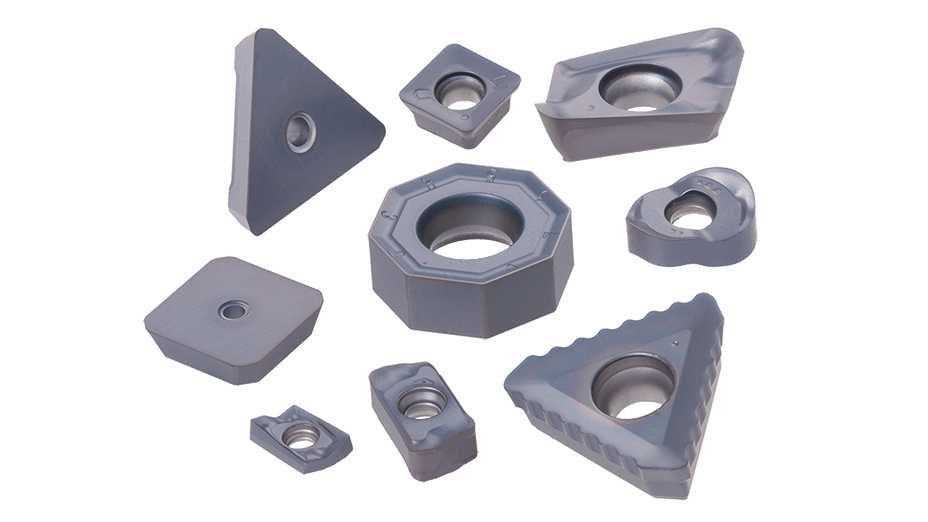

The AH3225 PVD-coated grade tooling from Tungaloy Corporation is now available across a wider range of milling tools including high-feed cutters (MillQuadFeed), face milling cutters (DoOcto), shoulder milling cutters (TungTriShred), and ISO insert geometries such as SDKN42 and TEEN32.

The AH3225 PVD-coated grade from Tungaloy Corporation is now available across a wider range of milling tools including high-feed cutters (MillQuadFeed), face milling cutters (DoOcto), shoulder milling cutters (TungTriShred), and ISO insert geometries such as SDKN42 and TEEN32.

To improve machining efficiency and extend tool life—particularly in ISO P steel applications, Tungaloy developed AH3225 with a proprietary "Triple Nano Coating" that the company says offers an excellent combination of wear resistance, fracture toughness, and oxidation resistance.

This technology ensures long tool life, minimizes dimensional variation, and delivers consistent machining quality even under demanding conditions.

The tooling grade provides resistance to crater and flank wear for extended tool life; reduced frequency of tool changes and stable machining across long production runs; and maintains surface quality and tight tolerances over time.

In addition, it enables faster cutting speeds and feed rates without compromising tool integrity. The tooling is ideal for high-feed and high-speed applications, reducing cycle times and overall machining costs