New end mills, drills, and insert

New end mills, drills, and insert

OSG USA Inc. released a range of new products to its tooling portfolio, including end mills, drills and inserts.

OSG USA Inc. released a range of new products to its tooling portfolio including end mills, drills and inserts.

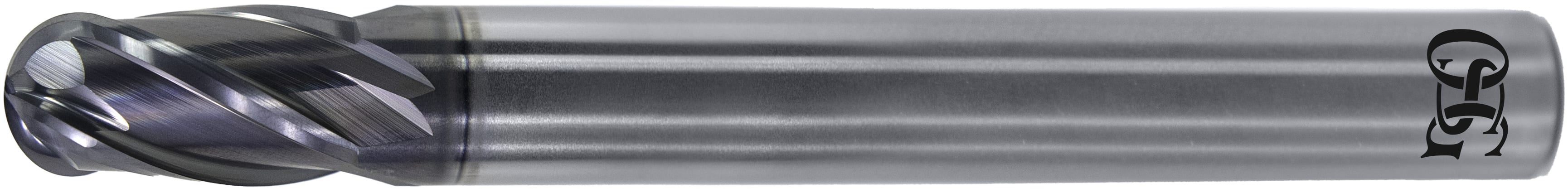

The end mill products include the A Brand AE-CPR2-H End Mill Series and the AE-CPR4-H, which is a series of advanced performance two- and four-fluted long neck corner radius end mills for hardened steels.

The following list numbers are associated with the expansion:

The A Brand AE-CPR2-H end mill offers the following features:

- 2-Flute Design - Low cutting resistance reduces tool deflection, ensuring a high-quality machined surface;

- Optimized 3D Negative Geometry - Balances sharpness and cutting-edge rigidity for superior performance;

- Flat Cutting Edge - Designed for bottom surface milling, achieving outstanding results with minimal tool wear while delivering higher precision and a smoother machined surface;

- Unmatched Corner Radius & Shank Precision - With a corner radius accuracy of ±0.002mm and an h4 shank tolerance for secure and stable tool holding.

The A Brand AE-CPR4-H End Mill Series features:

- 4-Flute Design - Achieves high efficiency milling with a 4-flute configuration across all sizes in List #8592;

- New Spiral Gash - For Improved chip evacuation and suppression of chatter

- Unequal Index - Suppresses chatter to enable high speed, deep reach milling

- Unmatched Corner Radius & Shank Precision - With a corner radius accuracy of ±0.002mm and an h4 shank tolerance for secure and stable tool holding

The company also released new versions of it Exocarb end mill series, including the Exocarb WXL-EBM. The Exocarb WXL-EBM is a series of premium performance

carbide end mills with OSG's proprietary WXL coating.

The following list of numbers are associated with the expansion:

The Exocarb WXL-EBM end mill offers the following features:

- Ultra-Fine Micro-Grain Carbide - The hardest, most wear-resistant carbide possible for wear resistance, the company says;

- High Precision Geometry - High accuracy all but eliminates the need for benching and rework for mold makers;

- High Strength Core Diameter - Tools utilize thicker core diameters for ultimate strength and rigidity;

- WXL Coating - Higher coating oxidation temp & hardness dramatically improve wear resistance.

The Exocarb SEP-EL is a series of DLC coated carbide end mills for super engineering plastics.

The following list numbers are associated with the expansion:

The Exocarb SEP-EL end mill offers the following features:

- DLC-IGUSS Coated - Combines microscopic tool sharpness & tool wear resistance while achieving a good surface finish in a range of plastics from engineering plastics to super engineering plastics;

- 3 Flute with Low Helix, Specialized for Resins - Cutting tool design allows for low cutting forces, reduced heat generation, and burr free machining;

- Strict Dimensional Control with Tool diameter Tolerances of 0.001" or Better - High accuracy tooling designed for the demanding needs of the semiconductor industry;

- Cutting Edge Ground to a Point - Resulting in a sharp cutting edge for free machining in resins

Drill series

OSG USA also announced the expansion of the A Brand ADO-40D and 50D Drill Series. The series now includes additional sizes in its offering. The A Brand ADO is a series of high-performance coolant-fed carbide drills for ferrous and non-ferrous materials.

The following list numbers are associated with the expansion:

The A Brand ADO-40D and 50D drill offers the following features:

- OSG's EgiAs Nano Coating Technology - Higher coating oxidation temp & hardness improve wear resistance;

- Wavy form cutting edge design - Sharper cutting action reduces thrust forces and produces smaller chips for easy hole processing;

- Internal Coolant Holes - Coolant delivery at the cutting edge reduces heat and improves chip evacuation, thereby increasing tool life and enabling faster drilling speeds.

New inserts

Finally, OSG USA released the OSG Phoenix PSF and PSFL insert. The insert is a 90° indexable shoulder cutter for face milling.

The following list numbers are associated with the expansion:

The Phoenix PSF/PSFL MCD Insert offers the following features:

- Square Insert with 4 Cutting Edges - High performance with long insert life and low cost per edge;

- Compact Insert Size for Lighter Depths of Cut - Superior performance in face milling applications;

- Sharp 3-Dimensional Chip Breaker - Reduced cutting forces;

- End Mill and Face Mill Styles, Inch and Metric - Complete offering