Horizontal bandsaw for bundled and solid materials

Horizontal bandsaw for bundled and solid materials

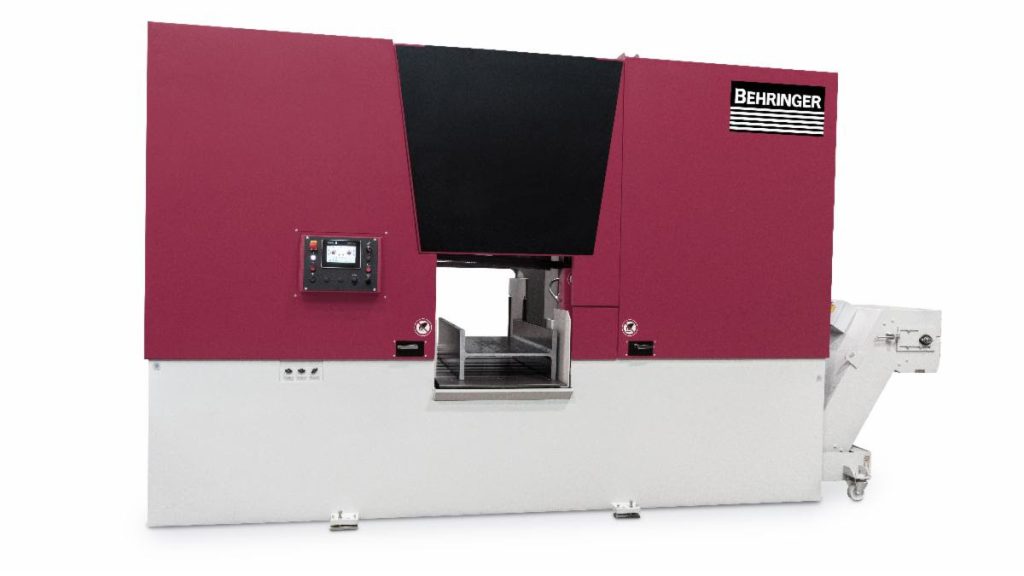

The HBE663A Dynamic horizontal bandsaw from Behringer Saws Inc. for sawing bundled materials features a double clamping vice that the company says securely clamps both the starting material and the finished cut, making it suited for bundle cutting or single cuts.

The HBE663A Dynamic horizontal bandsaw from Behringer Saws Inc. features a double-clamping vice that the company says securely clamps both the starting material and the finished cut, making it suited for bundle cutting or single cuts.

The retracting fixed vice jaws enable precise positioning of even strapped bundles, enhancing overall cutting accuracy, the company says. Robust vertical clamping devices ensure that bundles are securely held during sawing, providing precise and repeatable cutting operations.

The saw's servo down-feed system is powered by a ball screw and servo motor, which reduces idle times and enhances feed precision. According to Behringer, this results in higher cutting performance and extended band life, contributing to increased productivity and efficiency. The automatic guide arm ensures optimum sawing results without adjustments, even with frequently changing material sizes, making it versatile for diverse production needs.

The Behringer cutting pressure control system automatically adapts the saw feed to changing material cross-sections, which is particularly beneficial when sawing tubes and profiles. The Auto-Feed-Control (AFC) system utilizes an extensive material database to automatically calculate optimal values for saw feed and cutting speed, ensuring precision across a wide range of materials.

The feeding gripper handles heavy workpieces precisely, with optional single stroke feeding lengths of 1,500 mm or 3,000 mm, accommodating different production requirements. The machine's design promotes economical use of carbide saw blades through its robust construction, advanced servo technology, and efficient chip disposal. The heavy duty portal-design guide system combines a stable, low-vibration saw frame with a linear guide system to enhance precision and maximize service life.

The HBE663A Performance offers a cutting range of 26 inches for round materials and 28 x 26 inches for flat materials at 90°, allowing it to handle large workpieces. It can accurately process round materials as small as 0.8 inches in diameter and flat materials down to 0.8 x 0.8", providing flexibility for various material sizes. The machine is equipped with a drive power of 7.4hp and adjustable blade speeds from 33 to 360fpm, ensuring efficient cutting across different materials.

The chip conveyor system ensures optimal chip disposal with a funnel-shaped machine base and a paddle-style conveyor, featuring an integrated coolant tank. The cast iron band guiding parts, manufactured by BEHRINGER, provide vibration damping directly at the cutting edge, increasing tool life and enhancing cutting precision. The machine's dimensions of 88.6 inches in length, 173.2 inches in width, and 108.7 inches in height, along with a weight of 14,330 lbs, underscore its robust presence in production environments.

The HBE663A Performance offers individual configuration options, allowing users to tailor the machine to their specific production needs. This customization capability ensures that the saw operates at optimal performance and efficiency, aligning perfectly with the unique requirements of each production environment. By adapting the machine to precise production needs, users can maximize both performance and efficiency, making it an ideal solution for diverse applications.

With its combination of advanced features, precision cutting capabilities, and robust design, the HBE663A Performance represents a significant advancement in bandsawing technology. It is designed to meet the evolving demands of modern manufacturing, reinforcing BEHRINGER Saws; position as an industry innovator in high-performance bandsawing solutions. To learn more about the HBE663A Performance, click here.