Camera-based inspection system

Camera-based inspection system

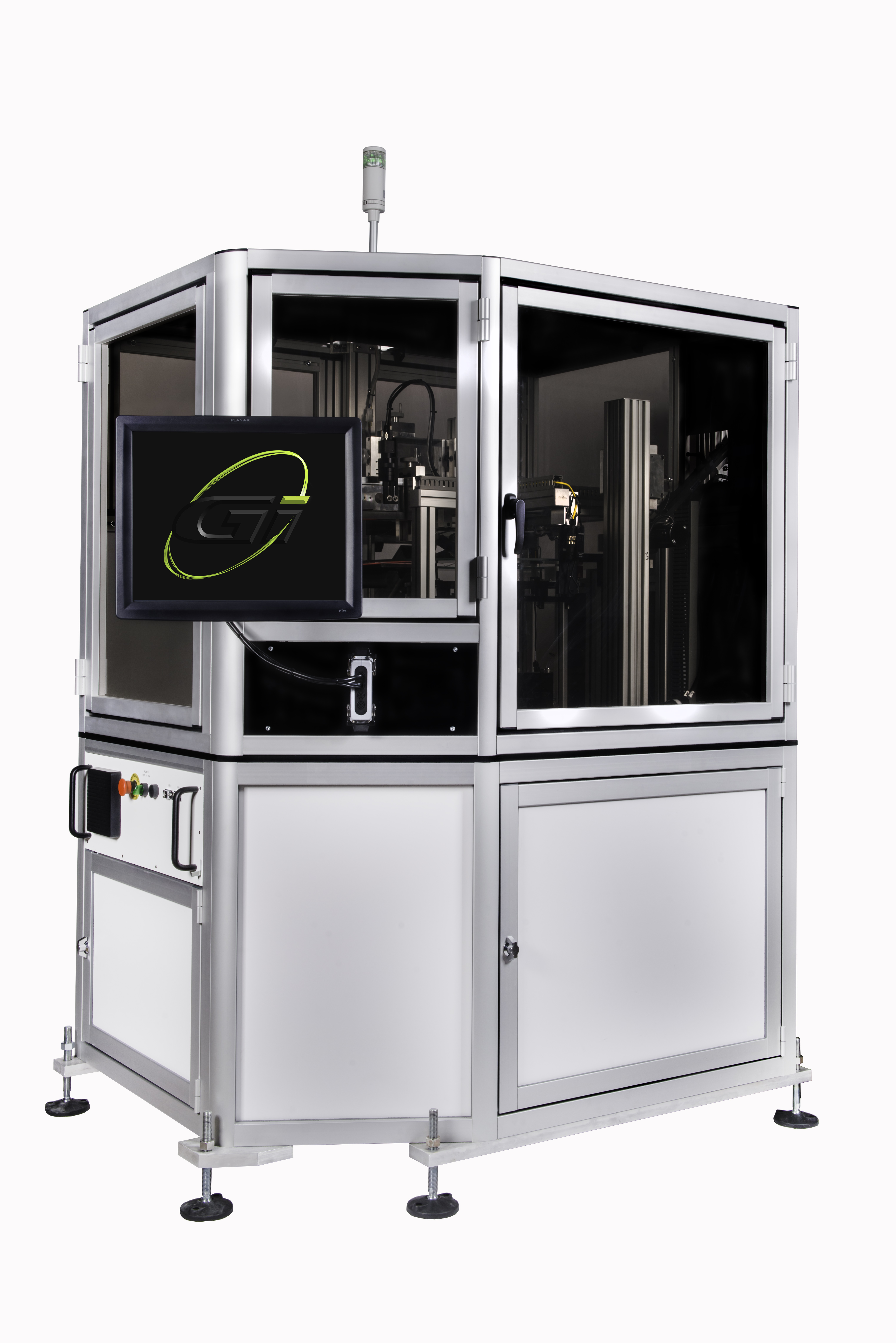

The Gi-100DT inspection system from General Inspection LLC is equipped with a total of six cameras providing complete dimensional inspection, internal and external visual defect detection, and top and bottom surface inspection for a full range of turned aerospace collars. For dimensional inspection, three cameras, one positioned from the side, one from the bottom and one from the top measures all profile features including threads, lengths, diameters, and angles. In addition to the dimensional inspection, the Gi-100DT detects surface defects on the top and bottom using three additional cameras to detect internal and external visual defects (360 degrees without part rotation). The surface defects include dents, scratches, chatter, pitting, and chips.

The Gi-100DT inspection system from General Inspection LLC is equipped with a total of 6 cameras providing complete dimensional inspection, internal and external visual defect detection, and top and bottom surface inspection for a full range of turned aerospace collars.

For dimensional inspection, the Gi-100DT comes standard with three cameras, one from the side, one from the bottom and one from the top. The system, which was recently installed installed at a California-based manufacturer of aerospace collars, bushings, and nuts, also features a side camera that measures all profile features including threads, lengths, diameters, and angles. The top and bottom cameras measure OD, ID, roundness, and concentricity. Parts can be measured to print specifications through Gi's software, and each dimension is saved and recalled by part number for fast part to part changeover. Defect detection, fast changeover, and inspection rates (minimum of 300 parts per minute) are achievable, the company says.

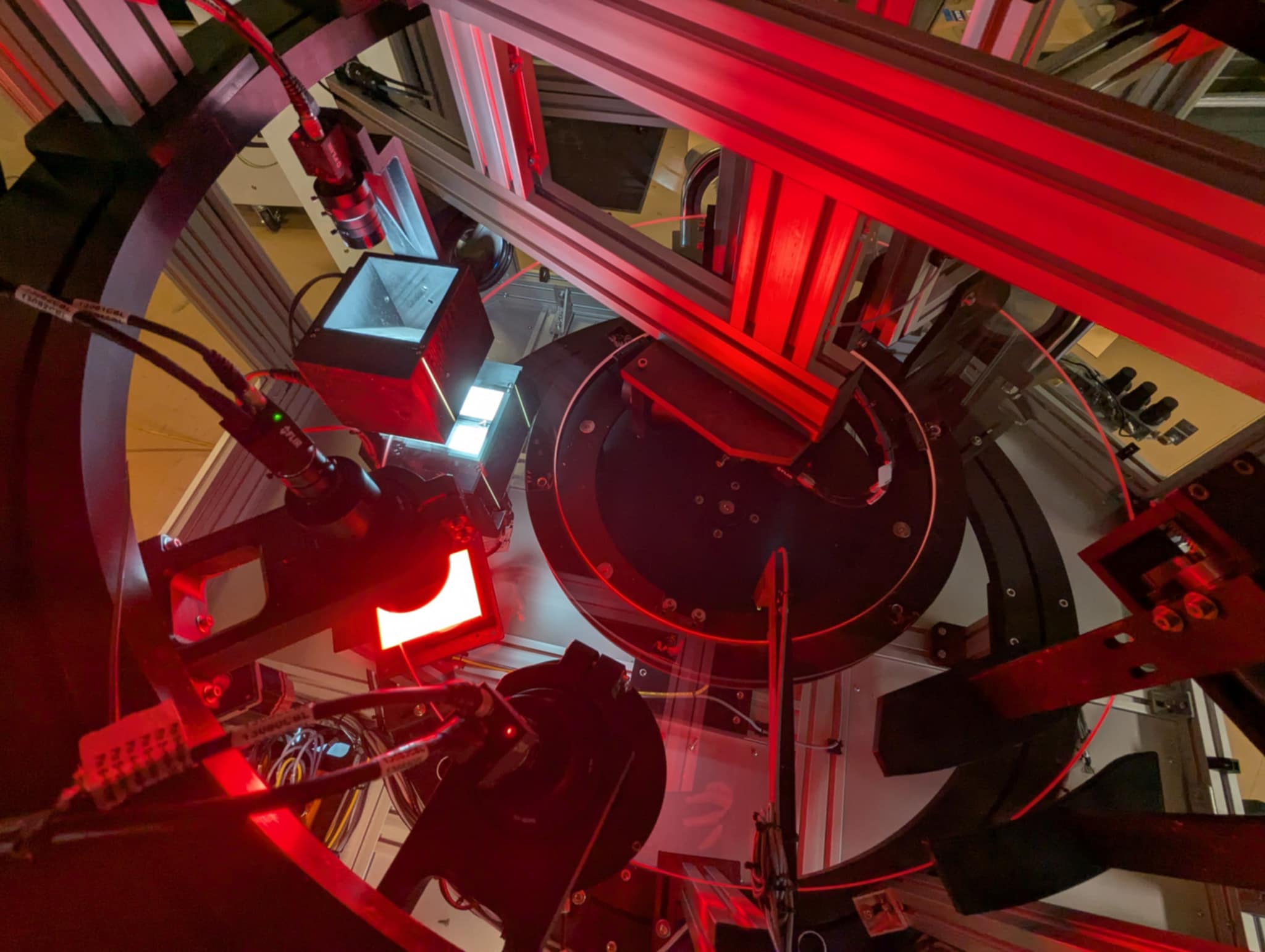

Gi-100 DT visual inspection system.">

Gi-100 DT visual inspection system.">In addition to the dimensional inspection, the Gi-100DT detects surface defects. The visual defect detection system is equipped with three additional cameras, each with patented optics positioned above and below the parts to detect internal and external visual defects (360 degrees without part rotation). The surface defects include dents, scratches, chatter, pitting, and chips.