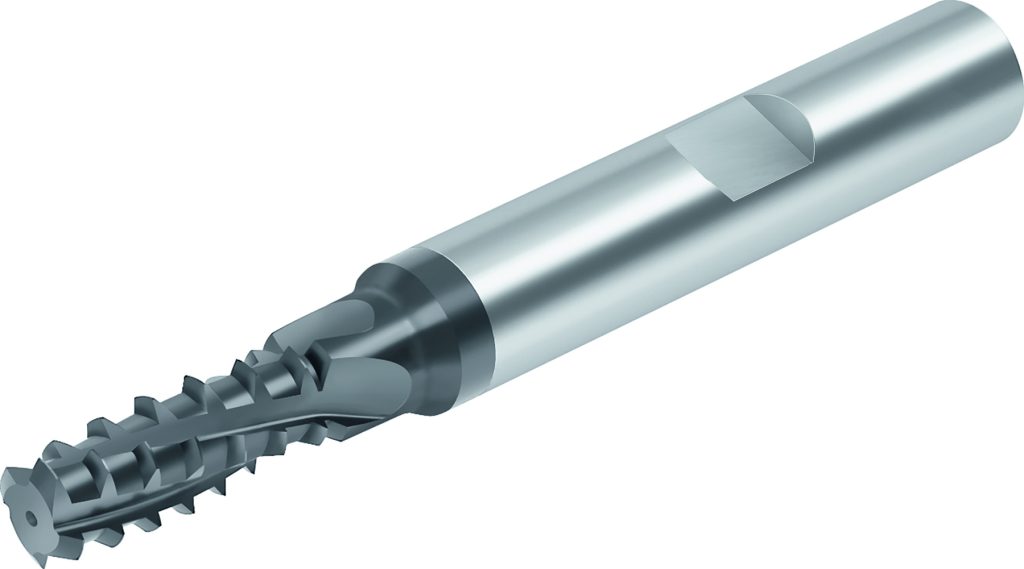

TC620 Supreme with countersink option

TC620 Supreme with countersink option

The TC620 Supreme thread milling cutters utilize patent-pending Walter DeVibe technology with an anti-vibration land to effectively suppress vibrations and allow higher cutting parameters, while contributing to other TC620 Supreme advantages like a high level of process reliability and easy handling due to extremely infrequent radius correction.

UPDATED 10/1/25

Walter USA recently added a new countersink option to its TC620 Supreme thread milling cutter lineup that features a multiple-row design for low cutting forces and excellent dimensional accuracy. Said to produce 90° chamfers by means of an axial movement, the new TC620 Supreme countersink option produces thread sizes of M3 to M20, M4×0.5 to M20×1.5, UNC 8 to UNC ¾, UNF 10 to UNF ¾, and G 1/16 to G ½.

ORIGINAL POST FROM 10/15/2022 FOLLOWS

The Walter solid carbide TC620 Supreme universal thread milling cutter, with internal coolant, and a multi-row design delivers greater productivity through design innovations that permit less vibration, reduced cutting pressure and excellent dimensional accuracy.

The TC620 Supreme thread milling cutters utilize patent-pending Walter DeVibe technology with an anti-vibration land to effectively suppress vibrations and allow higher cutting parameters, while contributing to other TC620 Supreme advantages like a high level of process reliability and easy handling due to extremely infrequent radius correction. A low cost per thread is another advantage thanks to fast machining time and longer tool life. DeVibe significantly improves the surface quality, especially with fine threads, regardless of clamping conditions, varying cutting values or the milling strategy.

The multi-row design thread mills are available in UNC, UNF, M and MF threadforms. Specifically: UNC8-UNC 7/8, UNF10-UNF ¾, M4-M20 and MF4-MF20 with DeVibe offerings starting at 5/16 and 8mm in each group. These new solid carbide thread milling cutters employ high-performance WB10TJ grade with a specially blended AlTiN coating, allowing maximum performance in many different materials, including difficult-to-machine materials, even under unfavorable conditions, aided by internal coolant that provides reliable chip removal even at high feeds per tooth.

The Walter lineup of products consists of three categories to tools. Supreme indicates the highest level of technology and performance available Advance which indicates product efficiently balanced between price and performance and Perform tools are products that provide an economical solution with focused importance on price.