AH3225 Insert Grade

AH3225 Insert Grade

AH3225 consists of the latest nano multi-layer coating technology with three major properties with excellent coating substrate adhesion for a high level of wear and fracture resistance. Integrating a dedicated carbide substrate with excellent thermal property provides the grade with increased thermal shock resistance and hardness reducing thermal crack generation on the cutting edge. This prevents unpredictable insert failure, significantly extending tool life and reliability for steel machining.

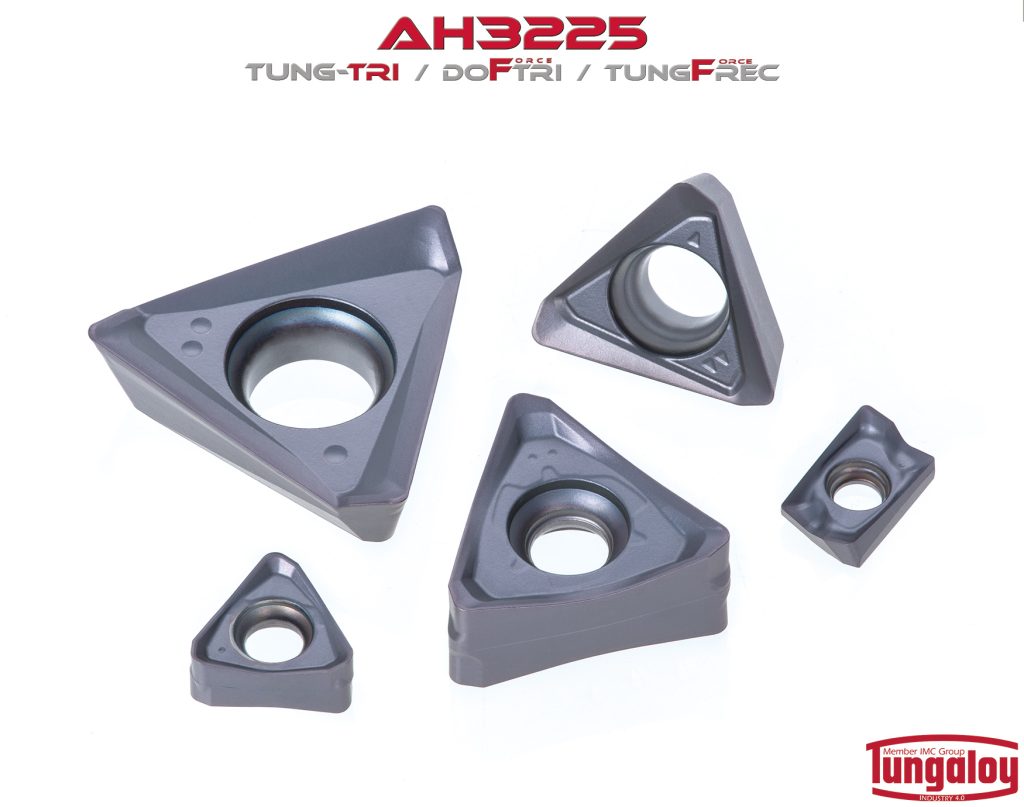

Tungaloy's square shoulder milling cutter series has been expanded with AH3225 insert grade designed to provide an excellent balance of wear and fracture resistance for superior performance in steel machining.

AH3225 consists of the latest nano multi-layer coating technology with three major properties with excellent coating substrate adhesion for a high level of wear and fracture resistance. Integrating a dedicated carbide substrate with excellent thermal property provides the grade with increased thermal shock resistance and hardness reducing thermal crack generation on the cutting edge. This prevents unpredictable insert failure, significantly extending tool life and reliability for steel machining.

A total of 28 new inserts have been added in this expansion to three lines of Tungaloy's finest square shoulder milling cutters: Tung-Tri boasts smooth cutting and exceptionally tool stability, TungForce-Rec features unique V bottom inserts for maximum productivity, and DoForce-Tri with its double-sided inserts with six cutting edges provides best production economy.