DrillMeister AH9130 Grade Drill Heads

DrillMeister AH9130 Grade Drill Heads

AH9130 is Tungaloy's latest PVD technology specifically designed for high-performance drilling applications. With better wear resistance compared with existing first-choice grade AH725, the grade delivers extremely long tool life in drilling applications, particularly of carbon steel and alloy steel.

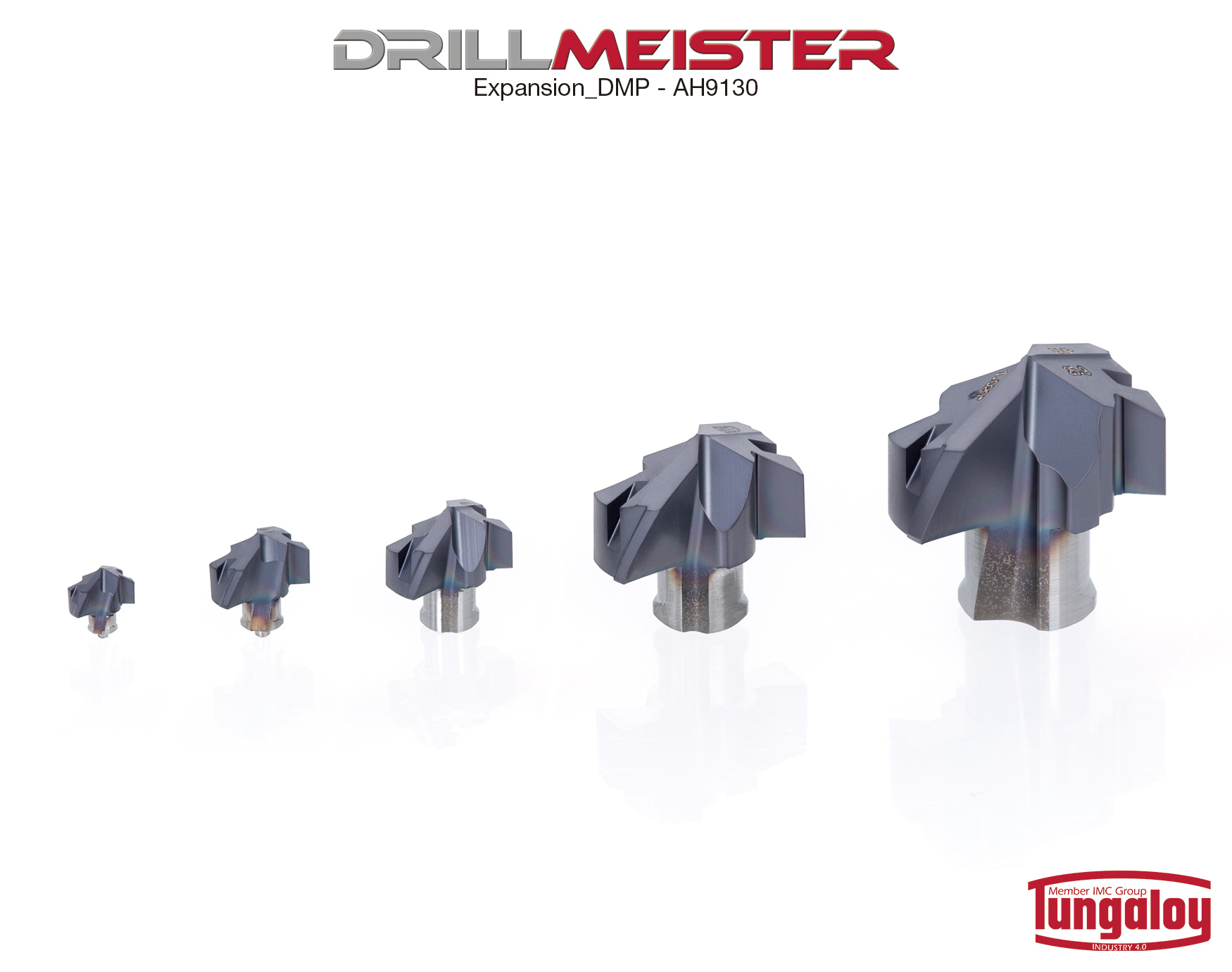

Tungaloy has further expanded its DrillMeister exchangeable head drill system by adding 30 more DMP drill heads in AH9130 grade to further improve the drill's wear resistance for general purpose drilling applications that require hole diameters ranging from 6.0 to 25.9 mm (.236″-1.020″). This expansion is scheduled to be completed by the end of August 2021.

AH9130 is Tungaloy's latest PVD technology specifically designed for high-performance drilling applications. With better wear resistance compared with existing first-choice grade AH725, the grade delivers extremely long tool life in drilling applications, particularly of carbon steel and alloy steel.

With increased DMP offerings in AH9130 grade, DrillMeister provides optimal solution with maximum tool life and wear prediction across all ranges of drilling applications.

The DrillMeister and DMP drill head

DrillMeister exchangeable head drills are a super productive, accurate, and cost efficient drill series. A single drill body can hold five different styles of drill heads in diameters ranging from 6.0 mm to 25.9 mm (.236″ to 1.020″). The drill heads are available in general purpose DMP style, DMC for high precision holes, DMH with enhanced drill corner geometry for drilling thin walls, DMF with flat edges ideal for counterboring, and DMN for non-ferrous applications.

The DMP style drill head features a 140 degree tip angle with a sharp cutting edge and optimized flute configuration that allows safe chip evacuation and tool stability.