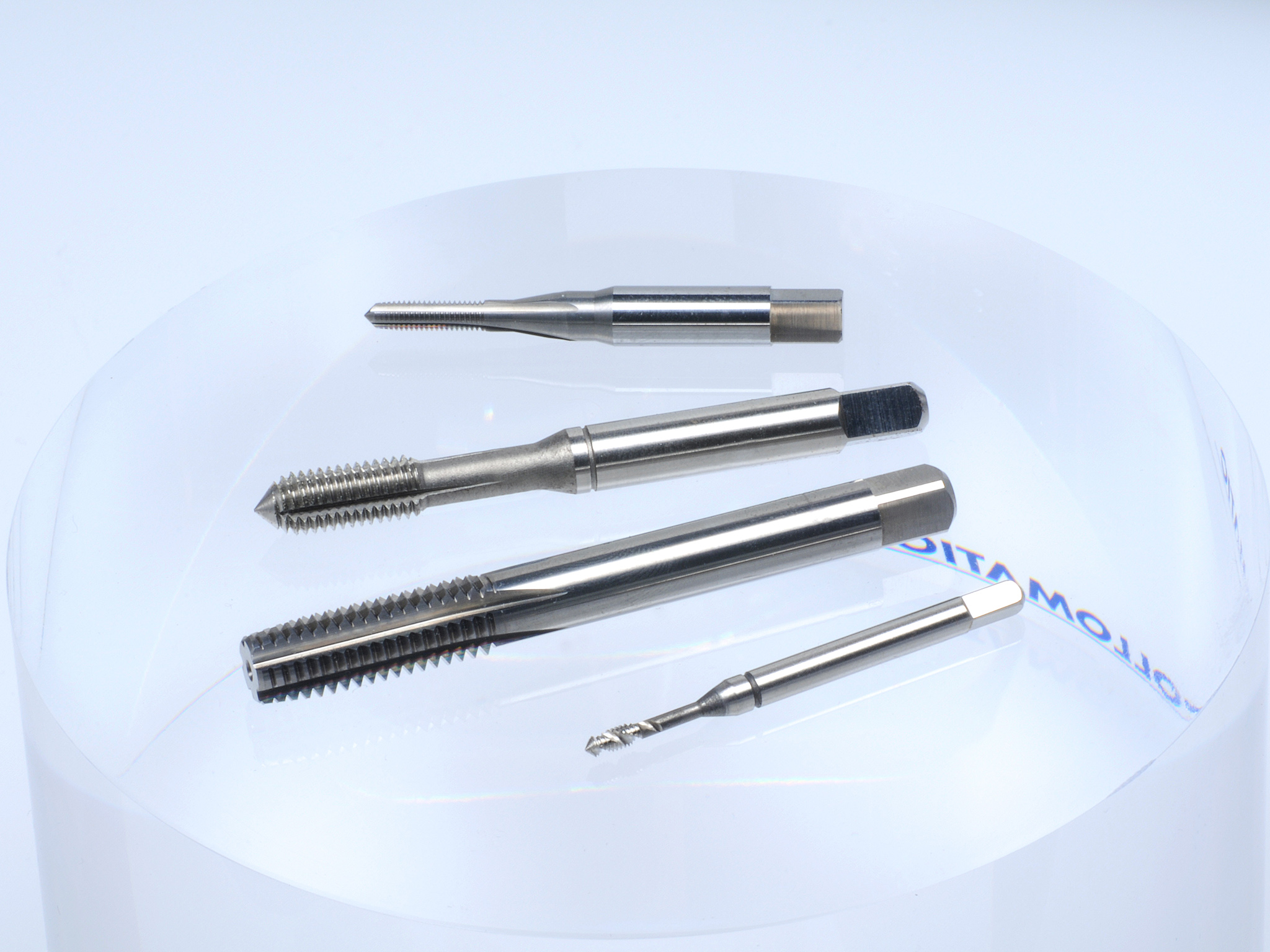

Taps and Threading Tools

Taps and Threading Tools

As the name suggests, cutting taps produce threads by progressively cutting away the space between threads into which the fastener's external threads will fit. Forming taps, by contrast, remove no material. Instead, they move or displace material inside the hole to build up the threads and dig into the grooves.

Rollomatic, a leading machine tool manufacturer based in Le Landeron, Switzerland, maintains its global leadership position in the field of multi-axis CNC grinding by presenting a variety of tool holding and software solutions for the production grinding of taps, threadmills and forming taps. The GrindSmart® 630XW is a modular tool grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpi…" title="Powers a grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpi…" aria-label="Glossary: grinding machine">grinding machine that provides ultimate versatility through customizable options. The ShapeSmart® NP50 is a pinch/peel grinding machine which is used for the blank prepara•on of these threading tools both in carbide, HSS and stainless.

Rollomatic has developed and refined several grinding processes that allow short and long batch grinding of threading tools where external thread grinding is an essential part of the manufacturing process.

- Cutting taps in HSS and solid carbide

- Surtical taps in stainless

- Straight-flute taps

- Spiral-flute taps

- Taps with gun point and/or chamfer

- Custom threads

- Threadmills in solid carbide

- Forming taps

Blank preparation including grinding of the shank, square and male centers

GrindSmart® 630XW 6-axis tool grinding machine:

- With 6-station wheel and nozzle changer

- Automatic tool loader/unloader

- Linear motion technology for improved surface finish

- Universal workhead with high-speed capability to combine high-accuracy cylindrical grinding and geometry grinding

- Large variety of workholding and tool holding solutions including custom-made fixtures

- Laser measuring included

ShapeSmart® NP50 5-axis pinch/peel cylindrical grinding machine:

- Automatic 3-axis tool loader/unloader

- Pinch/peel grinding process in combina•on with V•block part support and with simultaneous grinding of roughing and finishing passes

- Multi-pass grinding for efficient heavy stock removal

- Amazingly large diameter range from 0.0008" to 1"

- Patented non-round pinch/peel grinding for all non-round shapes such as square, rectangle, oval, corner radius and any other non-round profile

- Onboard diameter gauge included

Workholding:

Different types of tool clamping and support systems are available:

- The tap can be held between centers. The centers can be male or female on both the workhead and the tailstock. The tap is driven by a square clamp that acts as driver. The concentricity is provided by the two centers and not by clamping on the square.

- The tap can be clamped on the shank by a collet and supported by the tailstock. This mimics the way the tap is engaged in the ma•chine tool to cut the thread.

On-board dressing:

During the grinding process, the thread grinding wheel may potentially lose its profile and causes the thread dimensions to be out of tolerance. Utilizing predetermined parameters, a rotary onboard dresser will alloy the wheel to be conditioned for optimal grinding performance, while truing and restoring the form simultaneously. Here are diamond dressing rolls that can be used to dress diamond and CBN threading wheels including vitrified bonds:

- CVD or natural diamond rolls, hand-set or random-set

- Impregnated diamond rolls (sintered)

- Plated diamond rolls

Automatic loading/unloading:

The Rollomatic-designed high-speed tool loader which is integrated into the basic machine has been developed with rapid setup speed in mind, using pre•calibrated cassettes and a gripper design that allows holding different diameters without having to reset the gripper positions. The Rollomttic automatic loaders are known to be the most reliable in this industry. Mechanical quick-release clutches allow a rapid and easy recovery from any setup error.

The difference between cutting taps and forming taps:

As the name suggests, cutting taps produce threads by progressively cutting away the space between threads into which the fastener's external threads will fit. Forming taps, by contrast, remove no material. Instead, they move or displace material inside the hole to build up the threads and dig into the grooves.

The difference between taps and threadmills:

Thread milling uses helical interpolation for cutting the thread, while a tap is advanced into the workpiece in line with the center of the tool.