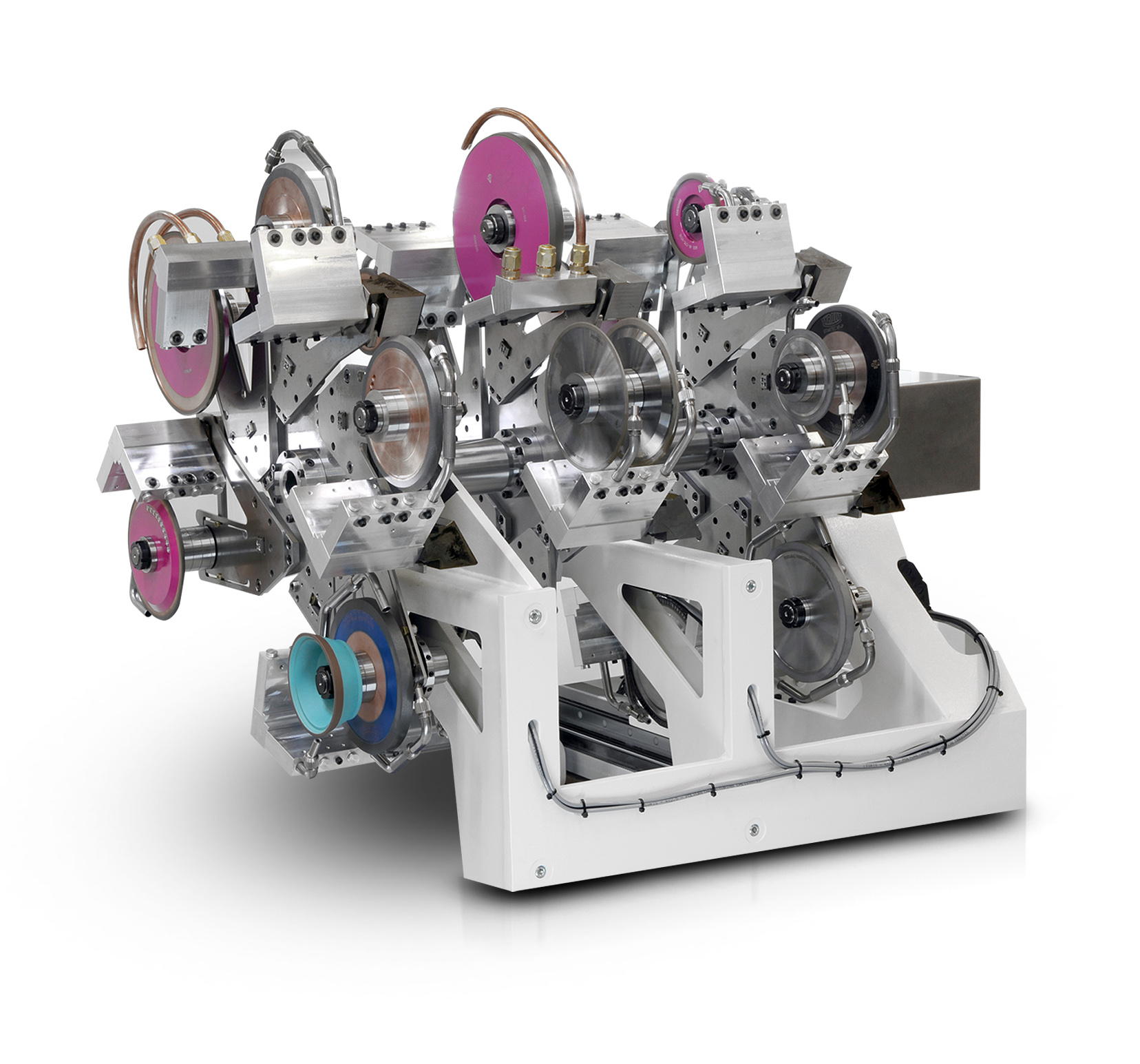

Model 630XW3 with a 16-station wheel changer

Model 630XW3 with a 16-station wheel changer

This model is part of the GrindSmart® series of tool & cutter grinding machines with an axis configuration that incorporate 6 fully interpolated axes (3 rotary and 3 linear) and is unique in this industry. The machine also incorporates linear axis drive technology. n

Rollomatic, a leading machine tool manufacturer based in Le Landeron, Switzerland, maintains its global leadership position in the field of 6-axis CNC tool grinding by highlighting the model 630XW3 with a 16-station wheel changer. This model is part of the GrindSmart® series of tool & cutter grinding machines with an axis configuration that incorporates 6 fully interpolated axes (3 rotary and 3 linear) and is unique in this industry. The machine also incorporates linear axis drive technology.

GrindSmart® 6-axis tool grinding machine with 16-station wheel and nozzle changer.

Highlights:

- Simultaneous change of wheel packs and associated coolant manifolds with coolant nozzles.

- World's smallest footprint of a 16-station wheel changer (only ads 30" to the width of the machine).

- Tool unload/load happens simultaneously during wheel change to shorten cycle time.

- Embedded intelligence to keep frequently used wheel packs in front to shorten cycle time.

- The wheel arbors are HSK-type with a proprietary attachment design that guarantees less than .00005" TIR over the life of the grinding spindle.

- Allows highest productivity in small-batch grinding of complex and high-performance cutting tools.

- Enhanced autonomy.

- Uses Rollomatic's VGPro desk top tool design program.

- Machines are assembled under a lean manufacturing program.