Automatic Work Wheel Balancing System

Automatic Work Wheel Balancing System

Real-time balance conditions are indicated on the HMI allowing technicians to predict when the wheel needs to be rebalanced before the surface finish degrades. With the Automatic Balancing System, the operator can balance the wheel successfully in as little as 5 minutes, regardless of skill level.n

Wheel balancing is crucial to achieving a good surface finish in the workpiece and is critical to the spindle bearing life.

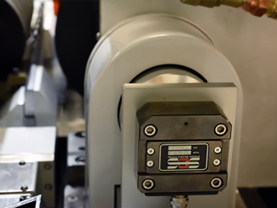

The Automatic Work Wheel Balancing System from Glebar Company dynamically balances the spindle through controls in the HMI. The automated system is more precise, ensuring the machine repeatedly produces a high-quality surface finish. As a result, the balanced wheel lasts longer and doesn't need to be dressed as frequently increasing productivity.

"Using the Automated Balancing System helps reduce the time spent balancing the work wheel by as much as 90%," said Mark Scanel, VP and General Manager of Glebar Customer Care.

Real-time balance conditions are indicated on the HMI allowing technicians to predict when the wheel needs to be rebalanced before the surface finish degrades. With the Automatic Balancing System, the operator can balance the wheel successfully in as little as 5 minutes, regardless of skill level.

The Glebar Customer Care team works with customers to minimize downtime and maximize the capabilities of their machines to increase production efficiencies.

The automatic wheel balancing system is available on Glebar's TF-9DHD Infeed/Thrufeed Micro Grinder, GT-9AC Guidewire Grinding Machine, and GT-610 Automated Infeed/Thrufeed Centerless Grinder.