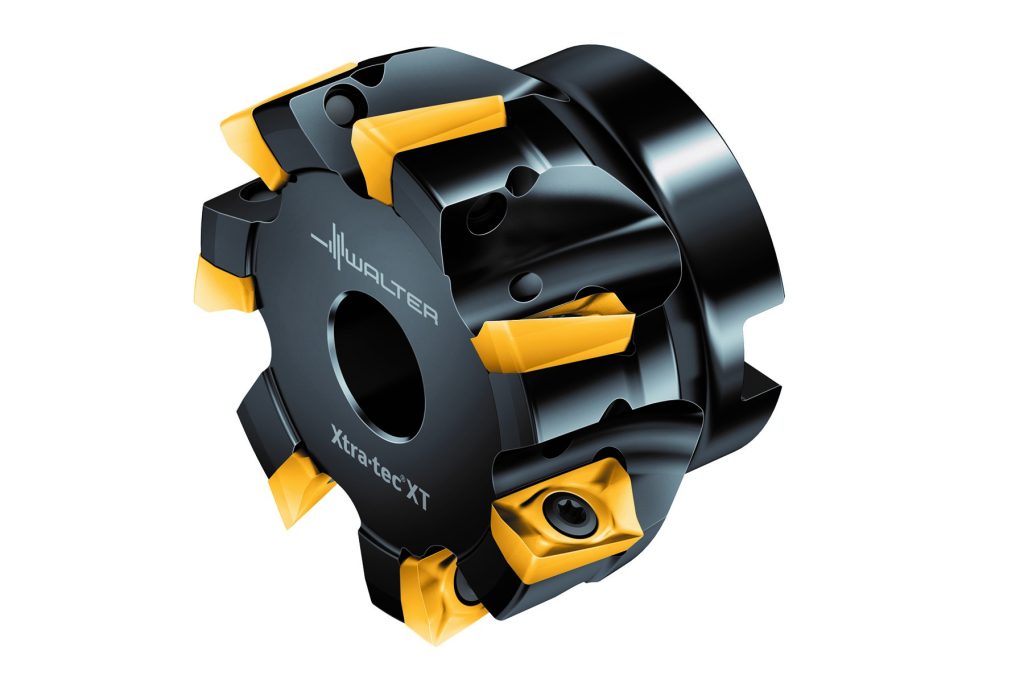

Xtra·tec XT M5130 Shoulder Milling Cutter

Xtra·tec XT M5130 Shoulder Milling Cutter

The mill is best suited to machining steel, stainless steel, cast iron, non-ferrous material and materials with difficult cutting properties. This wide range of uses results in lower tooling and administrative costs, as does the fact that its 90° approach angle dramatically decreases the need for finishing operations. Walter Tiger·tec cutting tool materials, the high number of teeth, and small indexable inserts also makes it ideal for workpieces with small machining allowances.n

Walter has introduced the Xtra·tec XT M5130 Shoulder Milling Cutter, a new universal tool that has been engineered for high productivity and optimum stability, resulting in superior process reliability. It handles a wide array of machining operations including face milling, shoulder milling, ramping, pocket milling, and circular interpolation operations. The mill is best suited to machining steel, stainless steel, cast iron, non-ferrous material and materials with difficult cutting properties.

This wide range of uses results in lower tooling and administrative costs, as does the fact that its 90° approach angle dramatically decreases the need for finishing operations. Walter Tiger·tec cutting tool materials, the high number of teeth, and small indexable inserts also makes it ideal for workpieces with small machining allowances.

The Xtra·tec XT M5130 Shoulder Milling Cutter features two pitches for different applications, and a stable cross section due to the modified installation position of the indexable inserts. Available in diameters of

0.5-6.0 in. (10-160 mm), and geometries F55, G55/G65, K55 and M85/K85, the Xtra·tec XT M5130 is ideal for the energy industry, die and moldmaking, as well as general metalworking.