INOEX Express-Service for Specials

INOEX Express-Service for Specials

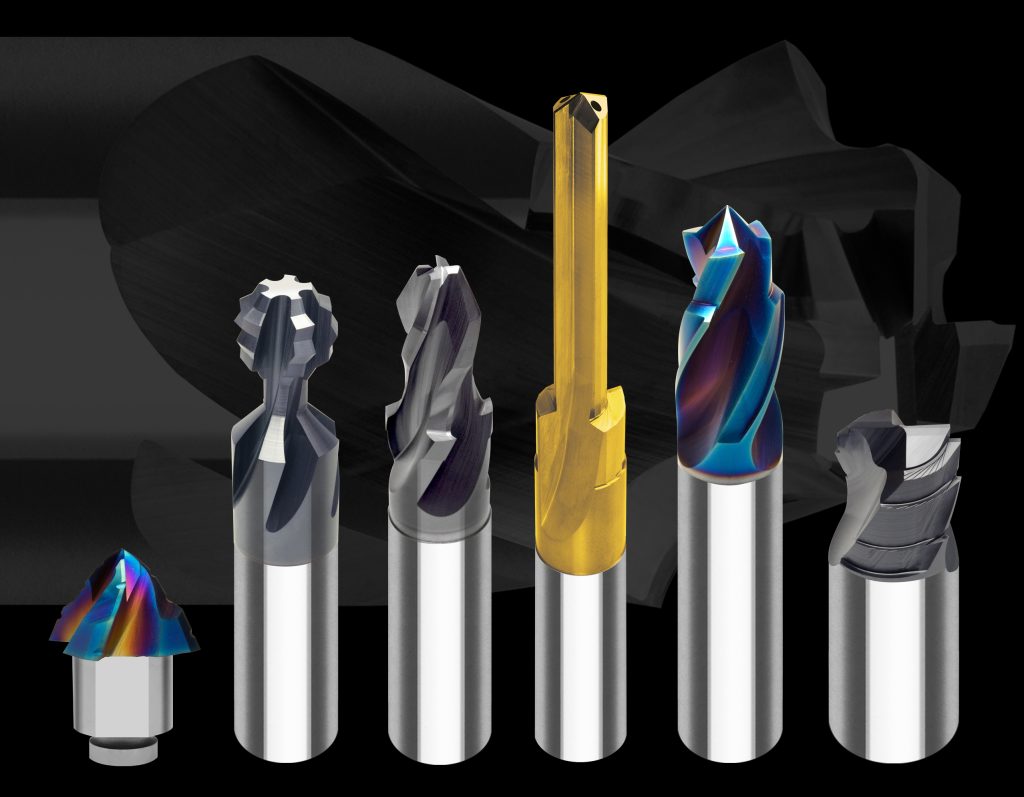

The production of special tools is a highly specialized discipline in tool manufacturing. Some manufacturers in the marketplace are good at this, but it is frequently the lead times that sort the wheat from the chaff. This is where tool manufacturer Inovatools comes in with its INOEX Express-Service: The company not only develops and produces special tools for complex drilling and milling tasks in the micron range, but also ships them within a week – including coating and tailored to meet specific customer requirements.

The production of special tools is a highly specialized discipline in tool manufacturing. Some manufacturers in the marketplace are good at this, but it is frequently the lead times that sort the wheat from the chaff. This is where tool manufacturer Inovatools comes in with its INOEX Express-Service: The company not only develops and produces special tools for complex drilling and milling tasks in the micron range, but also ships them within a week – including coating and tailored to meet specific customer requirements.

Sometimes in industrial production, in the face of new high-tech materials, highly specialized machining tasks and the constant pressure to increase productivity and efficiency, cutters find that standard tools are no longer up to the job. What's needed instead are special, application-optimized tools. Compared with conventional tools, special tools offer a range of benefits such as greater durability, higher quality and, on balance, greater cost-effectiveness in terms of unit costs.

Norbert Geyer, head of the special tools department at Inovatools: "We have set ourselves ambitious targets in terms of the lead times for special tools. A customer can receive within just 24 hours a quotation precisely tailored for their specific requirement. Development and manufacture begin as soon as we receive the drawing for the relevant tool or workpiece – complete with with dimensions and tolerances – from the customer."

Detailed information about the material to be machined, the machining strategy, information on the production machine and operating parameters such as cutting speed, feed values, coating, surface quality and so on ensure that the company can optimize the appropriate cutting materials, geometries and coatings for the specific requirements of the cutting task.

To create the ideal conditions for ultra-high-quality tools, Inovatools sources its premium carbide from a long-standing partner – after all, trust and quality are particularly important in this field. The high degree of vertical integration at Inovatools is another key advantage, meaning that the company has a wide range of edge preparation facilities in-house and can perform coating work itself. In combination with modern grinding technology in three-shift operation and the company's exceptional quality standards, the end result is a tool concept that completely fulfills every single production requirement. The large stock of semi-finished products with ready-made SC blanks significantly reduces production times and, in turn, delivery times.

Geyer said: "We are proud of our expert workforce that can now also handle complex and difficult tool orders with exceptional speed and professionalism. Thanks to our knowhow and technical preconditions, we can supply not only the standard product range but also supply special tools extremely quickly. For example, SC special-purpose drills and milling cutters with dimensions of 0.1 mm to 32 mm and featuring a special carbide substrate, customized coating, geometry and optimum chip grooves can be shipped to customers within one week."