HRT1000 and HRT100 Rotary Tables

HRT1000 and HRT100 Rotary Tables

Rotary tables are ideal for machining multiple sides of a part in a single setup or for machining many parts on a multiple-sided fixture. But handling very large or very small parts can prove challenging without the correct size rotary. The HRT1000 and HRT100 rotary tables from Haas Automation Inc. cover both ends of the size spectrum, providing high-precision 4th-axis positioning and simultaneous 4-axis motion for extra-large and extra-small parts.

Rotary tables are ideal for machining multiple sides of a part in a single setup or for machining many parts on a multiple-sided fixture. But handling very large or very small parts can prove challenging without the correct size rotary. The HRT1000 and HRT100 rotary tables from Haas Automation Inc. cover both ends of the size spectrum, providing high-precision 4th-axis positioning and simultaneous 4-axis motion for extra-large and extra-small parts.

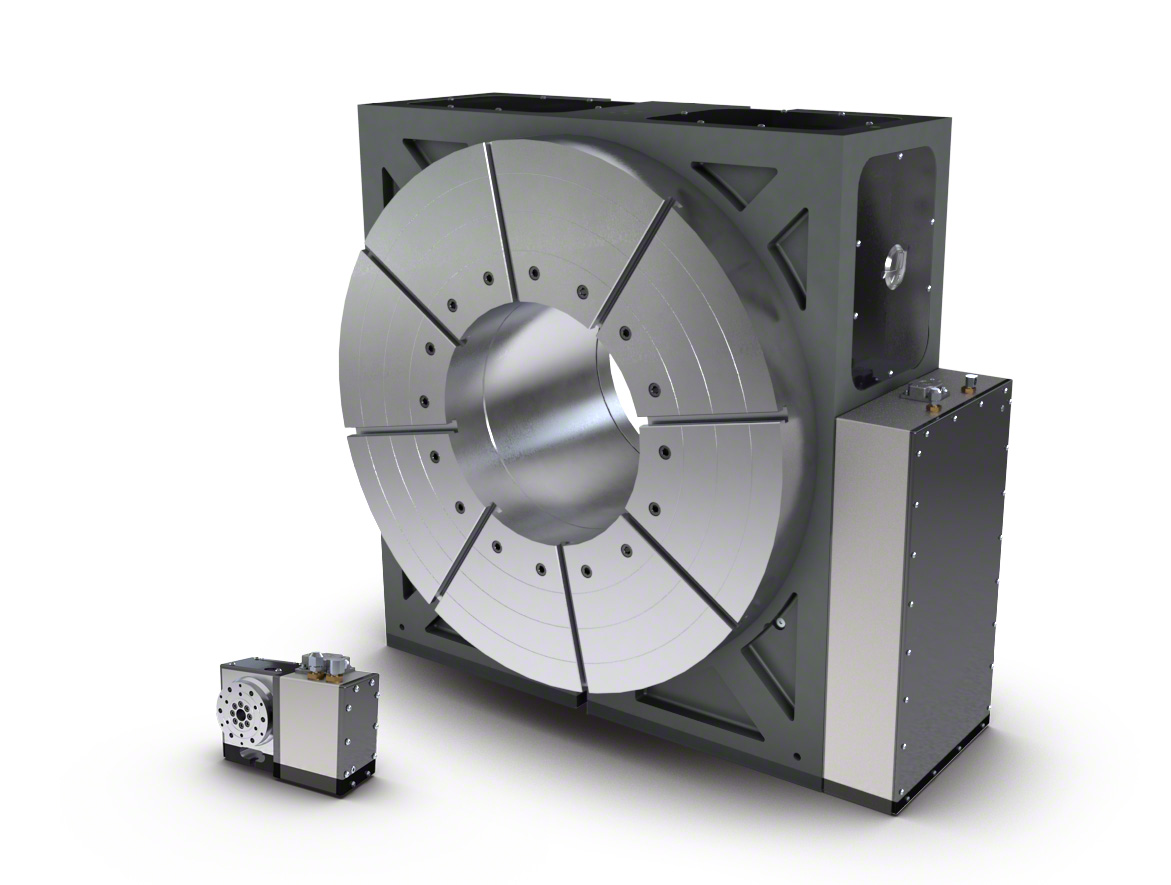

Whether you're machining large shafts for windmills, rethreading drill pipe or machining blowout preventers, the extra-large Haas HRT1000 rotary table has what you need to handle the big jobs. With its massive platter, generous torque and large through-hole, this extra-large rotary table will easily handle even the biggest 4-axis jobs in your shop.

The HRT1000 rotary table is one of three brand-new, extra-large rotary tables from Haas. It features a massive 1000 mm (39.37") T-slot platter, with a 17.50" (445 mm) through-hole to handle large shafts and fixtures. The HRT1000 provides 2000 ft-lb (2711 Nm) of cutting torque for simultaneous 4-axis machining, and offers 14,000 ft-lb (18,981 Nm) of brake torque to accommodate large parts and heavy off-center milling and drilling. The platter has 8 standard 5/8" (16 mm) T-slots arranged radially at 45 degree increments.

At the other end of the scale, the ultracompact HRT100 rotary table provides high-speed, accurate positioning and full 4-axis motion for machining small parts, such as those found in the medical, dental and electronics industries. Designed to complement the diminutive Haas CM-1 Compact Mill, the unit's very small size and light weight make it a suitable 4-axis solution for even the smallest machining centers.

The HRT100 provides 35 ft-lb (47 Nm) of cutting torque, and the 100 mm (3.94") platter indexes at 300 deg/sec for short cycle times. The platter has multiple bolt-hole patterns for flexible fixture mounting, and the table provides 26 ft-lb (35 Nm) of brake torque to handle off-center milling and drilling.