PlasticMetal Two-Component Repair Technology

PlasticMetal Two-Component Repair Technology

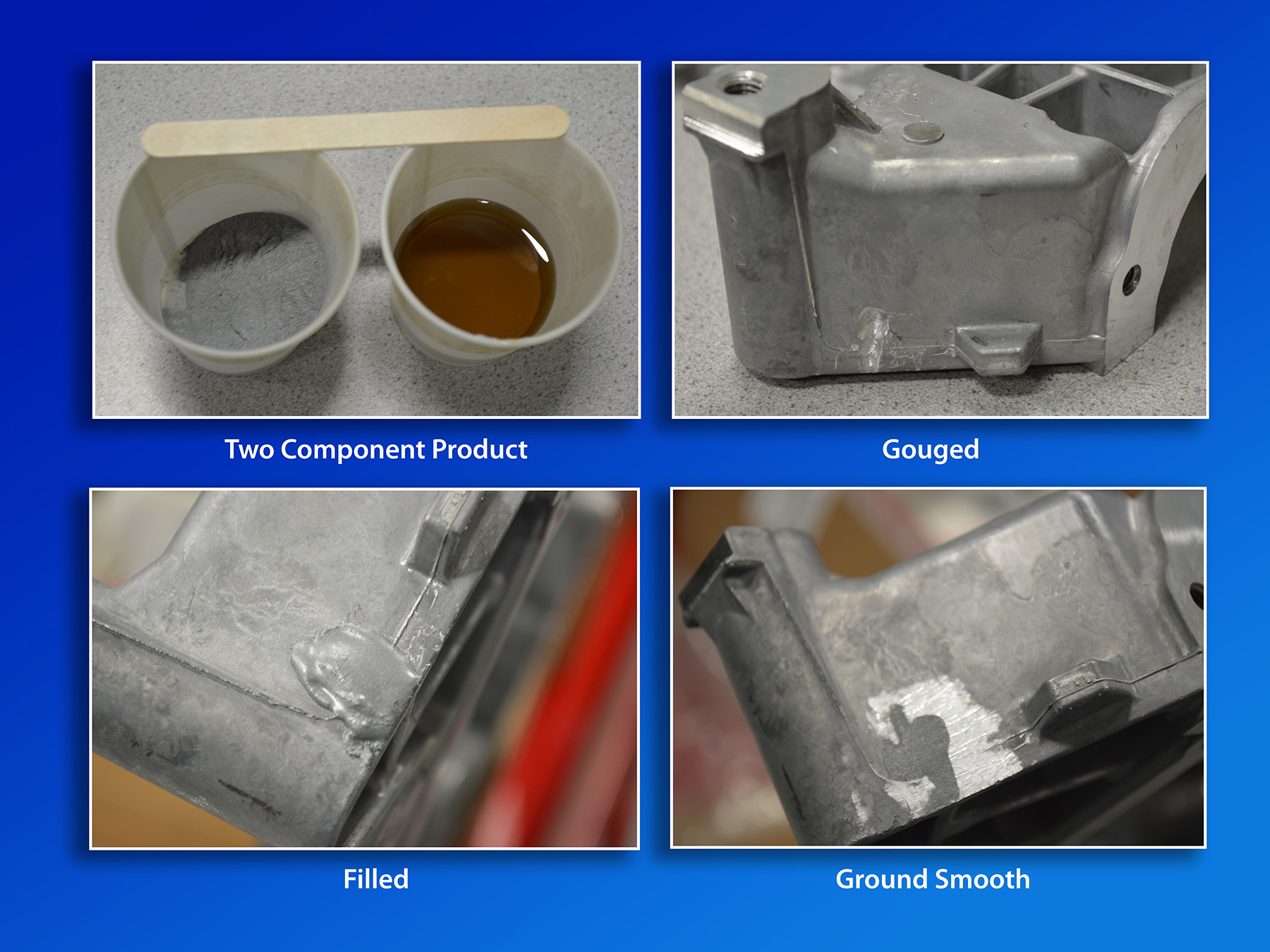

Stronghold Coatings introduces PlasticMetal, a two-component repair technology that can be mixed in various ratios for small and medium repairs to many types of metal. Unlike pre-mixed polymers, which have a set viscosity, this resin and powdered metal system can be mixed in small quantities in thicknesses to suit particular application requirements.

Stronghold Coatings introduces PlasticMetal, a two-component repair technology that can be mixed in various ratios for small and medium repairs to many types of metal. Unlike pre-mixed polymers, which have a set viscosity, this resin and powdered metal system can be mixed in small quantities in thicknesses to suit particular application requirements.

Whether used as a putty, paste or liquid, it yields high compression and tensile strength, and bonds to all metals. This fast-curing compound can be machined after hardening, making it ideal for the repair of defects, pin holes, blow holes and porosity in castings, and to repair machining errors and wear areas in cast iron, steel, aluminum and other alloys. It is highly resistant to physical and thermal stresses, including high chemical resistance, and temperature resistant to 250 degrees C (482 degrees F) continuous. With 12 formulations, including those for cast iron, steel, aluminum, bronze, brass, copper, red brass, iron oxide alloy and ceramic, there are thousands of potential applications across a wide range of industries.

When mixed with various hardeners, PlasticMetal can achieve specific characteristics such as viscosity, cure speed, appearance and performance. It can be applied in place with no special tools.