MTS 2.0 (Modular Tooling System)

MTS 2.0 (Modular Tooling System)

With total monitoring feedback, a maximum clamping power of 20,000 N and enhanced precision, the new MTS 2.0 (Modular Tooling System) fulfills even the most exacting machining demands. The use of state-of-the-art ceramic lock balls combined with innovative springs increase clamping power while allowing an opening pressure of only 6 bar.

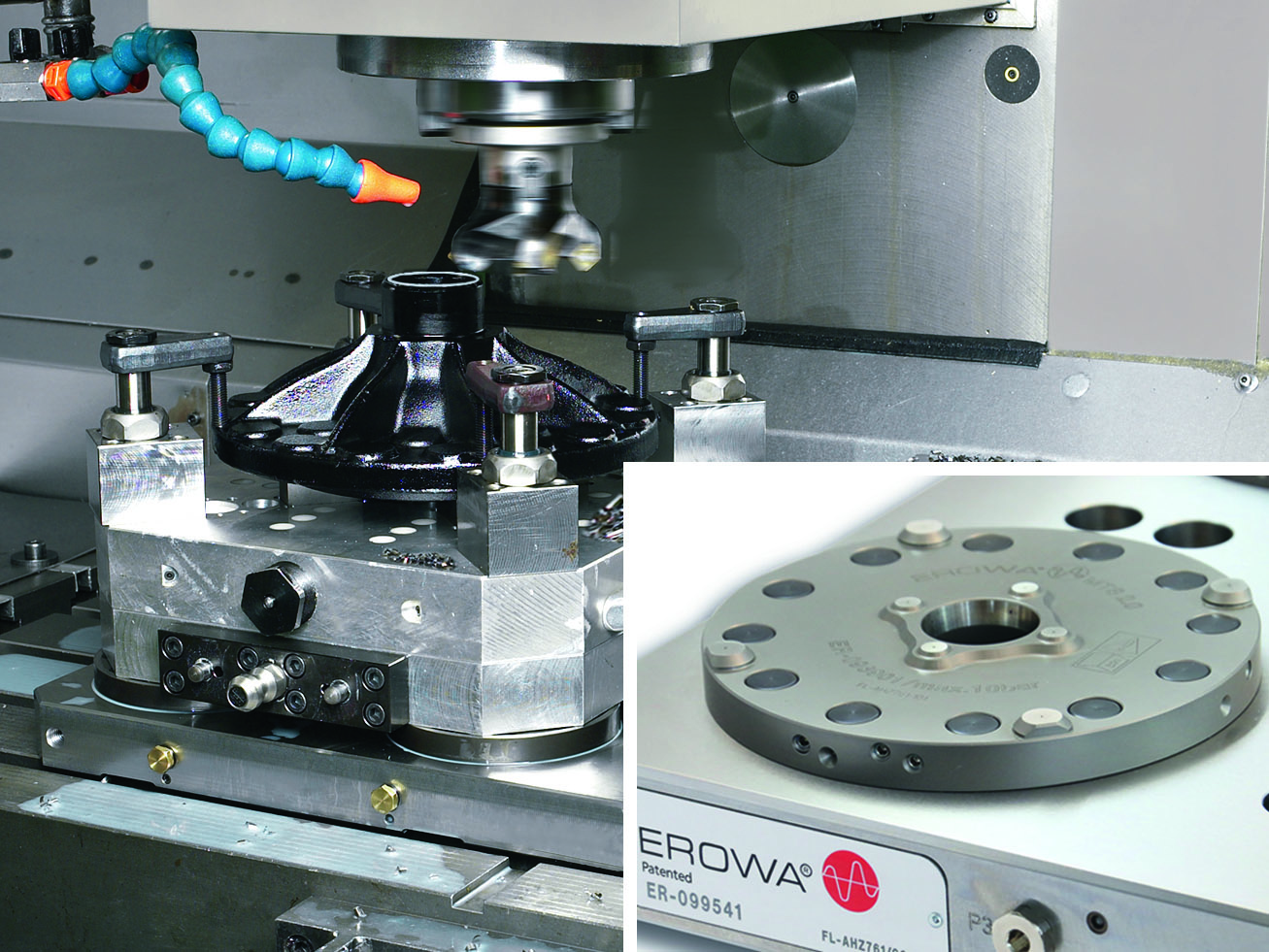

With total monitoring feedback, a maximum clamping power of 20,000 N and enhanced precision, the new MTS 2.0 (Modular Tooling System) fulfills even the most exacting machining demands. The use of state-of-the-art ceramic lock balls combined with innovative springs increase clamping power while allowing an opening pressure of only 6 bar. The MTS 2.0 also only needs 6 bar of pneumatic pressure for the "reclamping" function, which results in a clamping power of 20kN per chuck. This is an improvement of 60 percent when compared to the previous MTS models.

Used for single or multiple palletization, the pallets and the spigots of MTS 2.0 are compatible with the previous version and can be seamlessly integrated to any existing automation system.