Micro 5-Axis Milling Machine

Micro 5-Axis Milling Machine

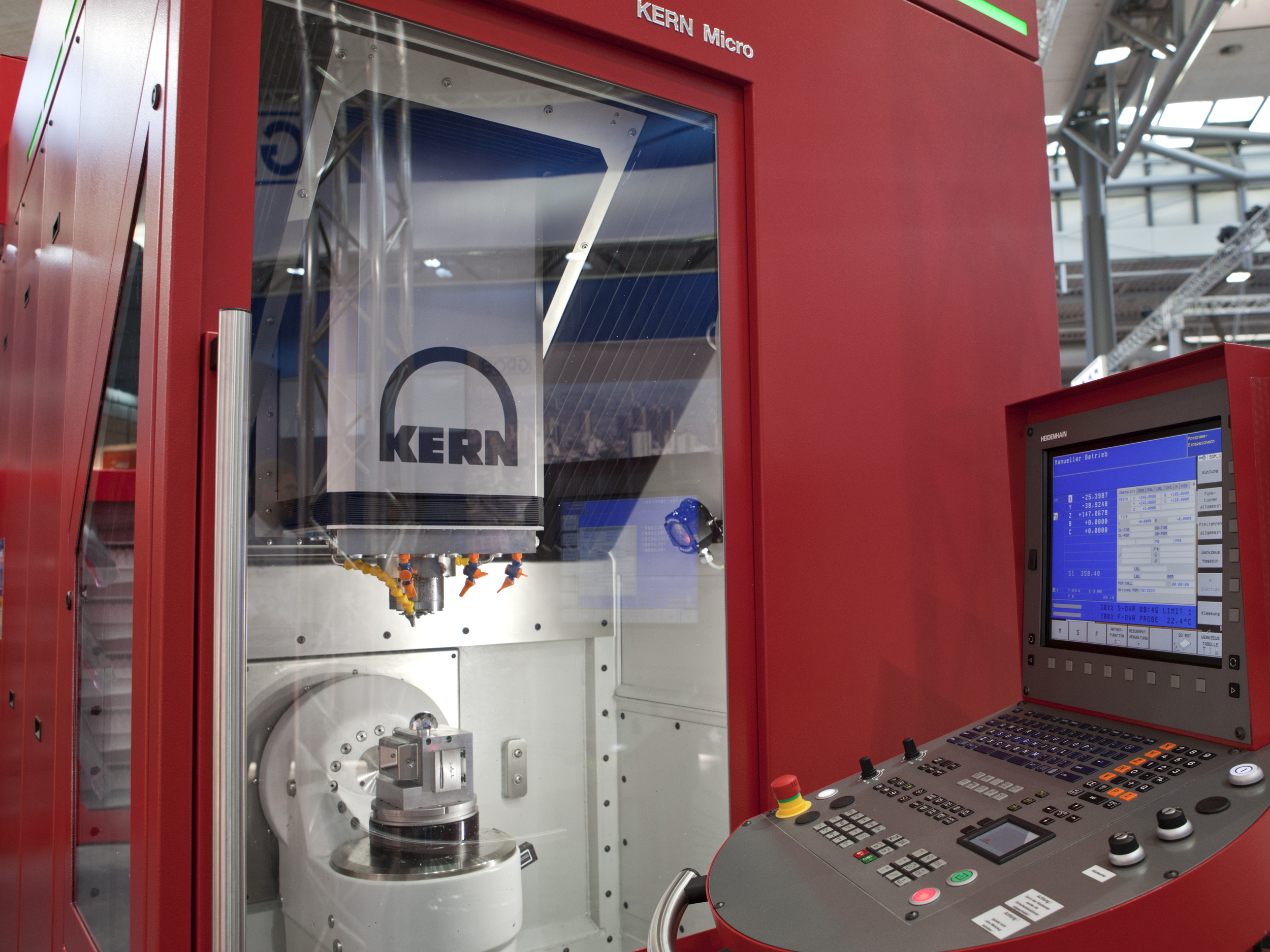

Kern Precision says its Micro 5-axis milling machine does not only tout its reliability and precision, but also the size of its footprint, the capacity of its palletized toolchanger, its plug-and-play capability, its power and its versatility in terms of the size of workpiece it can accommodate.

Kern Precision says its Micro five-axis milling machine does not only tout its reliability and precision, but also the size of its footprint, the capacity of its palletized toolchanger, its plug-and-play capability, its power and its versatility in terms of the size of workpiece it can accommodate.

"In general, the ultra-high precision milling market, where high productivity and precision are key, lacked a highly reliable five-axis machining solution," says Gary Zurek, Kern's sales manager. "The combination of high productivity and achieving ultra-high precision on five-axis and three-plus-two axis parts has always been challenging to manufacturers."

The KERN Micro offers manufacturers a diversified 5-axis machine that can bridge the gap among milling technologies, including high-speed machining, hard milling, graphite milling and micromilling, he says.

With its rectangular footprint, occupying just shy of 5 feet x 10 feet on the shop floor, the KERN Micro not only has a smaller footprint, the slim design means several machines can be lined up like row houses with other Micros for a highly automated work system.

"In today's economic climate, shop real estate is very expensive," says Zurek. "Doing more in a KERN Micro is a prized attribute, but if a machine is taking up a lot of shop space then that can be a negative factor."

If the Micro is small, its palletized toolchanger is just the opposite. The machine's tool cabinet is large enough to hold up to 209 tools and convenient to use because of its glass front. Quick-change tool pallets can be assembled for individual jobs and stored separately.

"For years now, the industry has recognized the advantages of modular fixturing and management in automated situations," says Matthias Fritz, KERN's R&D manager, adding that tool management can be a stumbling block in a highly productive environment. "Kern has applied this same technology to managing tool holders by palletizing them and managing them directly on the control."

The advantage is an easily managed and trouble-free system that contributes to the efficiency of the entire production cycle by significantly reducing setup times.

Not only tool changing, but also setting up the Micro is fast.

It's designed to be plug-and-play, with four connections required during setup for the machine, whose units are almost fully integrated: An optional water chiller is a standalone component. The cooling system is another master piece of Fritz. All relevant parts like spindle, axes and motor flunch are individually cooled and controlled. The cooling system is basically a heat exchanger and with the chiller being outside the machine there is no waste heat inside the machine. With temperature being a major issue for accuracy especially in production cycles, this solution is simply ingenious.

With its HSK 40 spindle with internal coolant lubrication, not only can shops achieve micron-level precision on micro-size parts, they can also cut more than 70 lbs. of steel in an hour. An HSK 25 spindle is available as an option.

Further, due to an integrated fourth and fifth axis table in a traveling column machine design, the Micro can handle workpieces up to almost 14 inches in diameter. The intelligent arrangement of the fourth and fifth axes results in a large swivel range that allows full use of the working area.