Universal Twin-Turret Grinding Machine

Universal Twin-Turret Grinding Machine

Fives' Universal Landis Twin Turret grinding machine's newly configured design provides a common platform for multiple machine configurations and processes. It is far stiffer than conventional machines, features remarkable thermal stability, and offers a compact machine footprint, according to the company.

Fives' Universal Landis Twin Turret grinding machine's newly configured design provides a common platform for multiple machine configurations and processes. It is far stiffer than conventional machines, features remarkable thermal stability, and offers a compact machine footprint, according to the company.

Fives' longtime grinding expertise, in conjunction with its history alongside the Landis and Cranfield Precision range of products, led to the development of the Universal Twin Turret grinder.

The Landis Twin Turret (LTT) series machines are designed for superabrasives, and perfectly suited to process extremely challenging materials and geometries common in various industries and markets such as aerospace, automotive, fuel systems as well as optics and precision components. This model provides a common platform for multiple machine configurations and processes, including OD, ID and profile grinding, milling, polishing, hard and diamond turning, dicing, and in-situ metrology. Supplied in two sizes, the LTT-100 and LTT-400 are multifunctional machines that handle workpieces as large as 100 mm and 400 mm in diameter, respectively.

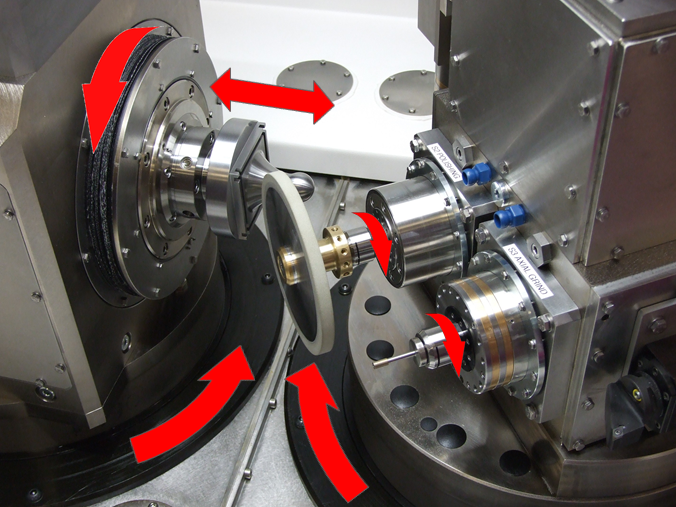

The Universal Twin Turret grinder enables sub-micron position control. Two rotary axes are rigidly mounted on a fixed center distance and provide relative motion between the component and cutting tool, with the linear axis used to control the depth of cut and profile shape of the component being machined. Its unique combination of rotary and linear axes produce relative motion between tool and workpiece over a swept working area.

This machine concept is radically different, as it coordinates the two rotary axes and a short linear axis in a Twin Turret design to provide far stiffer results than standard machines, as well as remarkable thermal stability. Gone are the inherent thermal stability and stiffness issues that plague conventional machine platforms using stacked linear axes.

The twin turret design enables a simple non-contacting labyrinth seal, making the machine base almost immune to distortions. A far cry from traditional machine designs that suffer from the ever-changing coolant return path and heat transference from the grinding process, resulting in constant variable machine distortions.

The LTT was designed to use the minimum number of bearing interfaces in the machining loop, to maximize machine loop stiffness. Two highly damped hydrostatic bearings are employed and the machine's turrets are bolted together via a solid granite base plate to resist machining forces and improve precision and repeatability.

The unique configuration of the LTT also provides a compact machine footprint that is typically 40 percent smaller than similar machines. This frees up more room on the job shop floor for other workpieces, additional work-flow margin, and/or space for inventory.