Vibration Damping Technology

Vibration Damping Technology

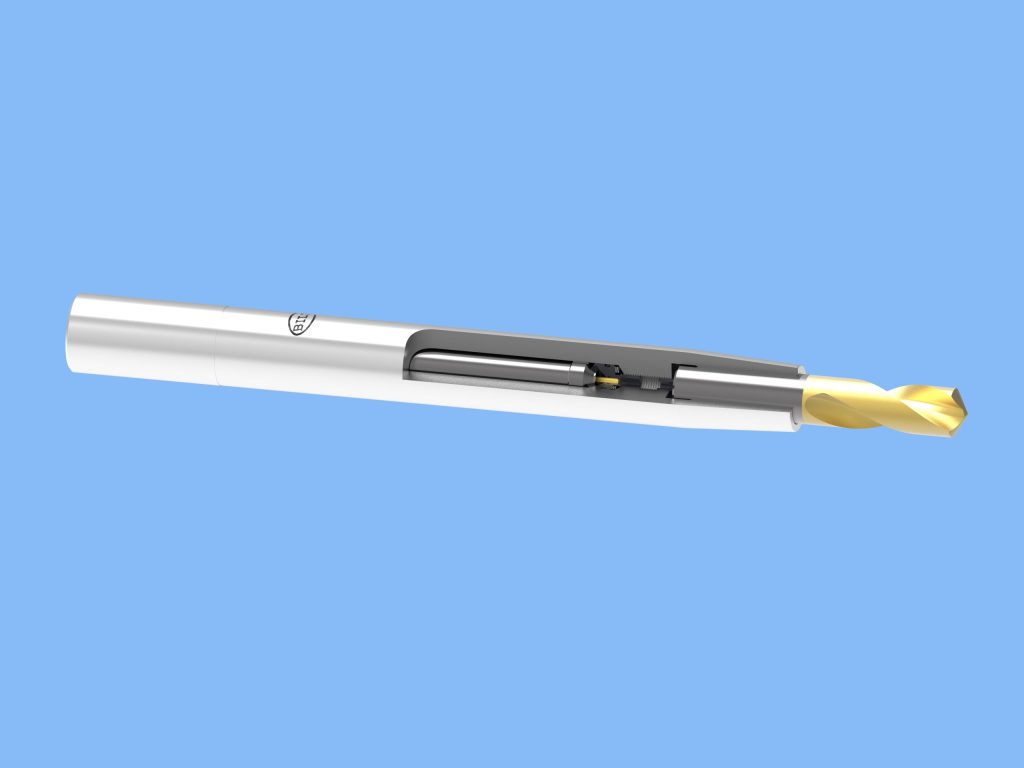

Particularly long, slender extensions often have a tendency to bend and vibrate. Whennmachining long overhangs in hard to reach areas such as deep cavities, the VIbration DAmpingnTechnology, VIDAT, from Bilz Tool Co. Inc. can be used.

Particularly long, slender extensions often have a tendency to bend and vibrate. When

machining long overhangs in hard to reach areas such as deep cavities, the VIbration DAmping

Technology, VIDAT, from Bilz Tool Co. Inc. can be used. With an integrated damper, these extensions reduce the

relatively quick vibrations and thus ensuring an extensive vibration- and chatter free machining.

Without vibration damping, the tool holder is confined to the limits of machining with large L/D

ratios.

The VIDAT extensions provide a much higher cutting depth which increases the metal-removal

rate enormously. Compared to standard extensions with a similar projection length, the process

can be performed faster with improved service life and process safety, resulting with a

smoother and chatter-free workpiece surface.

By using the BILZ VIDAT extensions you can:

Reduce the vibrations in the clamping system,

Improve the surface quality of the work piece,

Increase tool life,

Increase mrr.

BILZ VIDAT extensions have a h6 shank tolerance and can be both shrunk and stretched with

other clamping devices for cylindrical shanks. The extensions are available with a range of

tool diameters of 6mm to 20mm, with total lengths of 210mm or 300mm available. The VIDAT

extensions are suitable for up to 80 bar of internal coolant supply.