Special Dual-Contact Toolholder

Special Dual-Contact Toolholder

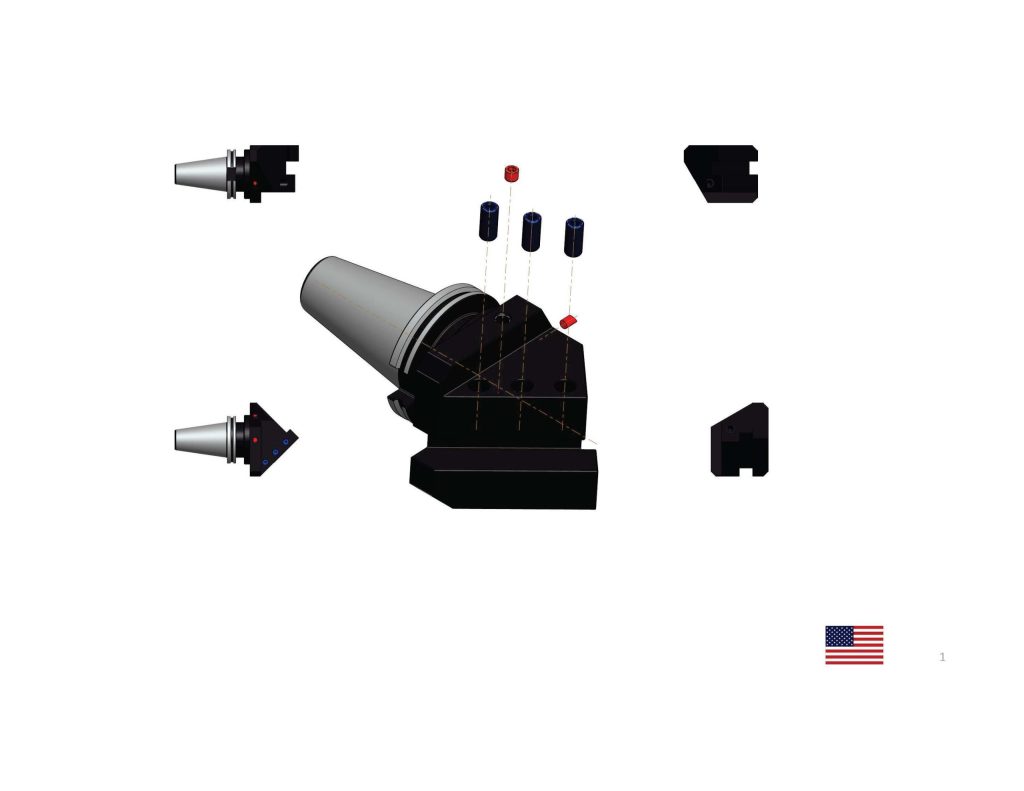

Briney Tooling Systems worked closely with a manufacturer to develop a special dual-contact, CAT 50, stick turning toolholder for an Okuma MacTurn 550 mill/turn center. The customer had some special turning stick tools that were 1.5-inches square and there was no standard for the lathe stick tools.

Briney Tooling Systems worked closely with a manufacturer to develop a special dual-contact, CAT 50, stick turning toolholder for an Okuma MacTurn 550 mill/turn center. The customer had some special turning stick tools that were 1.5-inches square and there was no standard for the lathe stick tools. Briney Tooling Systems was able to analyze the tool and determine the correct cutting angle required for the stick tooling and built custom adapters that ultimately saved the customer from having to reengineer its entire catalog of stick-type lathe tooling.

Many of today's machining centers, like the Okuma MacTurn 550, are equipped with dual-contact spindles, where there is dual contact between the machine spindle taper and the toolholder taper shank. The benefit is improved rigidity that ensures accuracy and surface finish, extends tool life and minimizes deflection and vibration for high speed machining. Combine that spindle with a dual-contact toolholder and you have the best of both worlds. The dual contact of the toolholder taper shank and the toolholder flange is a method to eliminate pullback of the toolholder. The steep taper contacts the spindle taper and flange contact on the spindle face, making a solid union in both the axial and radial planes. As a result, dual contact toolholders are resistant to axial movement because the face contact prevents the toolholder from being pulled up into the spindle at high speed. Briney has been providing dual contact toolholders for many years, so applying that capability to the Okuma MacTurn lathe tooling was easily accomplished.