Quill Support for Advanced Milling

Quill Support for Advanced Milling

Further enhancements to the recently-introduced Waveform Roughing strategy, and Quill Support for advanced milling, are just two of the significant features in the latest release of the CAM software, Edgecam, from the Vero group.

Further enhancements to the recently-introduced Waveform Roughing strategy, and Quill Support for advanced milling, are just two of the significant features in the latest release of the CAM software, Edgecam, from the Vero group.

Unveiled in the previous edition, the Waveform Roughing Strategy offers even greater stability, more precise machining and faster metal removal. The new Edgecam 2012 R2 takes this advanced process to the next level, including improvements to the entry methods, ordering and calculation speeds.

General Manager Raf Lobato says: "The Waveform Roughing Strategy gives improved tool life, constant engagement with material and constant chip load, superior material removal rates, and an improved surface finish which potentially eliminates secondary cutting cycles."

The new Advanced 5 Axis Simultaneous Milling license introduces new parameters to control the toolpath, a new dialog with images to help explain the options available and the option to machine multi-blade components.

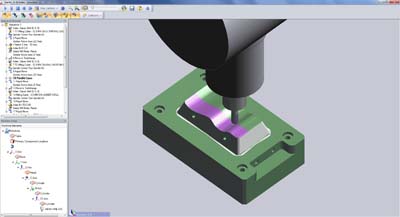

Quills (secondary Z axis) can now be included in milling machine configurations, enabling the user to switch between the z axes, control which one is in use, and see the quills movement in Simulator.

Lobato says: "Edgecam 2012 R2 includes further improvements to the User Interface making Edgecam even more intuitive and easier to use."

When editing an Edgecam cycle the original geometry picks are now retained and do not need to be reselected unless the user chooses to. A similar time saving feature is the improved picking of edges on solid models and 2D profiles, ensuring that the user has full control of picking entities that will be used by other functions within Edgecam.

And to make it easier to manage a large set of machining instructions, it is now possible to group a number of instructions into user defined sets within the sequence browser.

External rotary slot and pocket features along a cylinder solid model can now be identified for subsequent machining. The feature attributes help the user to select the correct tool and machine the feature in rotary mode.

Steadies can now be included in Turning and Mill/Turn machine configurations, and included in the simulation of the machining sequence in Simulator.