Turbomax Endmill

Turbomax Endmill

Without some sort of "turbo" attachment, you won't get far trying to dry-machine Inconel or titanium with a conventional end mill. In the form of the universal end mill series Turbomax, tool manufacturer InovaTools has reportedly delivered a multi-talented product.

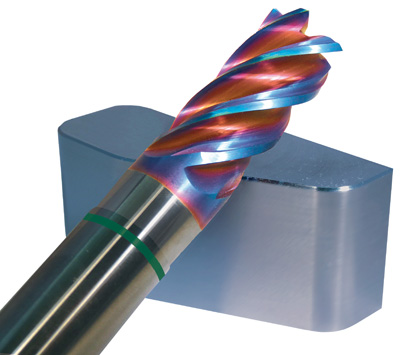

Without some sort of "turbo" attachment, you won't get far trying to dry-machine Inconel or titanium with a conventional end mill. In the form of the universal end mill series Turbomax, tool manufacturer InovaTools has reportedly delivered a multi-talented product. Thanks to its special geometry, chip control and coating, this product can achieve increases in productivity and quality improvements for dry machining of steel materials, Inconel and titanium in comparison to conventional tools.

As a genuinely universal all-rounder for trimming, roughing and finishing in mechanical engineering, the automotive industry, aeronautical and aerospace engineering as well as medical engineering and mold and tool construction, the Turbomax end mill from InovaTools proves its value in daily use.

Tobias Eckerle, technician at InovaTools: "The Turbomax end mills have an improved geometry with an uneven cutting edge spacing, a conical core diameter, 5 polished teeth and 1 tooth above the center. The bottom line is that, compared to similar tools from the Asian and German market, end milling can be performed with far lower levels of vibrations. This improves the surface quality and reduces the strain on the tool."

InovaTools also treats the Turbomax end mills to the company's own Naco-Blue coating and an additional end finishing. This smooth high-performance coating allows the chips to flow away very easily and also has a positive effect on the service life of the tools. This means that they no longer have to be changed as quickly, and cost-effectiveness is increased in an optimized process.

Turbomax is available in a range of diameters from 6mm to 20mm. The tools are available with HB and HA shanks, and wet and dry machining is possible up to less than 1,400 N/mm2/45 HRC.

In practice, the design advantages are reflected in the productivity levels. One example of this is in mechanical engineering, in the trimming of a motor housing made from non-rusting, austenitic steel, material 1.4301: compared to the 4 teeth in the reference tool, the Turbomax used has 5 teeth. With ap = 16mm, ae = 4mm, Vc = 80 m/min and N = 1,600 rpm, the Turbomax achieved a feed rate per tooth of fz = 0.08 compared to fz = 0.06 in the reference tool.

Tobias Eckerle said: "Depending on the application, the Turbomax offers customers a service life up to 2.5 times higher than that of the end mills they have used up to now. They can also increase their productivity by up to 50 percent using our universal end mills."