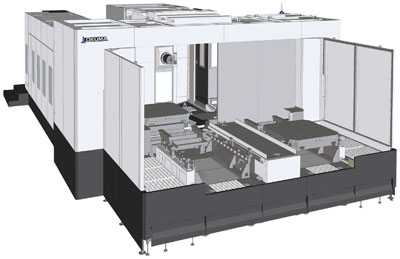

MA-12500H Horizontal Machining Center

MA-12500H Horizontal Machining Center

Okuma's MA-12500H horizontal machining center provides a good balance of speed and cutting power for machining of aluminum alloys, cast iron and difficult-to-machine materials.

Okuma's MA-12500H horizontal machining center provides a good balance of speed and cutting power for machining of aluminum alloys, cast iron and difficult-to-machine materials. This makes it well suited for large part aerospace machining. The MA-12500H is the machine of choice for building lathes at the Okuma DS1 plant in Oguchi, Japan.

Built on an integral bed and base, and designed with reinforcing ribs for increased stability and load carrying capacity, the MA-12500H incorporates Okuma's exclusive Thermo-Friendly concept to achieve maximum thermal stability and accuracy. Standardly equipped with a 50 taper 6,000 rpm, 60/50 horsepower spindle, it is also available with either a 12,000 rpm wide range spindle or 4,500 rpm heavy duty spindle.

• Maximum load capacity of 11,000 pounds

• Rapid traverse (X, Y, Z) of 1,653 ipm

• Maximum part size: 78.72" diameter x 62.99" high, 10,141 pounds

• Axis travels: X-86.61", Y-62.99", Z-64.96" 0.001 degree

• B-axis rotary table 49.21" square pallet

• Parallel-type 2 pallet

• APC 81 tool matrix

• ATC standard, up to 171 tool matrix optional