Version 28 CAD/CAM Software

Version 28 CAD/CAM Software

BobCAD-CAM says its new Version 28 CAD/CAM software makes CNC programming faster, easier, and more efficient than ever before.

BobCAD-CAM says its new Version 28 CAD/CAM software makes CNC programming faster, easier, and more efficient than ever before. It builds on 30 years of CAD/CAM innovation which includes a powerful 2D & 3D CAD design system, an easy to use wizard driven CAM Programming interface, Dynamic Machining Strategies, advanced 2-5 axis high speed adaptive toolpath capabilities and realistic simulations.

The new v28 CAD/CAM software for CNC programming delivers even more drawing control in CAD, upgrades to the intelligent hole drilling system, the ability to create custom tool shapes for milling tools and enhancements to wrapped toolpath capabilities.

This release was all about expanding high-performance CAD/CAM functionality to enhance machining power, efficiency, and control aspects while maintaining the same ease of use that users depend on to get jobs done faster with superior results, according to the company.

Snap Increments for Dynamic Drawing (Extrude, Rotate, Sketch) – Drawing is now faster and more accurate than ever. All dynamic drawing functions now have snap increment, which acts like a uniform grid in the workspace to which wireframe entities or sketch handles are snapped. Included is a snap increment distance, which is used for most dynamic functions and a snap increment angle for rotation functions. This creates a whole new level of efficiency for dynamic drawing by greatly reducing the number of clicks and data entry modifications. Just set the snap increment and adjust it as needed right from the status bar to create perfectly accurate drawings. This feature can easily be turned on and off with shortcut keys.

Drill Multiple Depths in a Single Feature – All mill hole drilling, tapping, and threading features now use Hole Groups that allow you to define more than one drilling depth within a single machining feature. The software automatically groups all holes that share the same diameter, top of feature, and feature depth, greatly minimizing the number of features needed to get the job done. This makes your drilling features more efficient that ever. You can edit faster and gain greater control of the rapid movements between hole groups using the new Group Retracts.

Advanced Retract Options – The new Group Retracts provide advanced options for defining rapid movements between hole groups. Create planar, cylindrical, or spherical retract areas for all types of drilling scenarios. You can even create the rapid movement to follow the tool orientation or the shortest distance to keep the toolpath clean and efficient.

Standard Drilling – This is the default drilling type that handles 2.5 axis drilling for 3 axis machines, including face drilling for mill turn machines.

Multiaxis Drilling – Multiaxis drilling is a completely new drilling type that handles all drilling for 4 or 5 axis machines with up to 5 axis positioning. This allows you to drill holes of the same diameter in any orientation within a single feature, eliminating the need to create index systems for each orientation.

Cross Drilling – Cross drilling is a completely new drilling type that handles radial drilling for mill turn jobs. Hole Geometry Selection Manager

Hole Geometry Selection Manager – The new selection manager for mill hole features makes it easy to define the drilling type and manage geometry selections. Calculation options are provided to determine how the toolpath is calculated for different geometry types, providing greater efficiency in selection scenarios.

Smart Filtering of Geometry Selections – The software automatically filters geometry selections in two ways: 1. Any duplicates that would result in drilling a hole twice are automatically removed. 2. Geometry selections are filtered based on the drilling type. Once you confirm the selection, all holes that do not have the proper orientation for the selected drilling type are removed.

Use Cylindrical Surfaces to Automatically Set Drilling Parameters – When you select cylindrical surfaces, the software automatically sets the diameter, top feature, and feature depth values for you. Select cylindrical surfaces to speed up your mill hole feature creation.

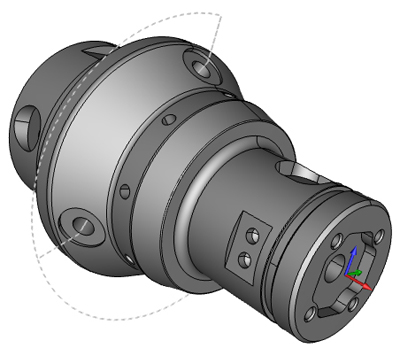

Custom Tool Shapes for Milling Tools – When creating milling tools, you can now assign geometry to define custom shaped tooling or form tools. You can even define the cutting and non-cutting portions making it easy to create tools that have more than one cutting area. Just create half of the profile to revolve, assign it to the tool, and get accurate programming simulation for all of your custom tooling.

Tabbing for 2 Axis Profiling – The 2 axis wizard now contains a Tabs page, which allows for manual or automatic tab creation for profiling operations. You can allow the software to automatically calculate evenly spaced tabs using a number or distance, or you can manually select the tab location directly from the chains in the workspace. Powerful tab parameters allow you to define tab distance, height, and angle.

Linking Added to 2 Axis Advanced Pocket – The 2 Axis Advanced Pocket now contains a links page giving you more control over the linking parameters of the toolpath. Use a direct, S-link, or retract move between passes or groups with separate controls for each. You can also use the rapid retract for large gaps to speed up the retract moves when there are large gaps along the cut.

Perpendicular Stepover for Advanced Planar – The Advanced Planar operation is further optimized with a new solution for inconsistent finishing in steep areas. The perpendicular stepover option automatically switches the toolpath direction based on a threshold value to create an improved surface finish in steep areas. This efficient toolpath provides a better finish result and reduces cycle times.

Round Corners for Advanced Planar – You can now smoothen the tool movement at sharp corners created in the Advanced Planar toolpath using round corners. Create a more consistent tool engagement and smoother transition for your semi-finishing material removal.

Side and Bottom Allowance – This allows you to specify the finishing allowance separately for the side (XY) and bottom (Z), giving you more control over the roughing toolpath so you can minimize or even eliminate the semi-finishing process for your 3 axis operations.

Wrapped Toolpath Improvements – The Wrapping Group for 4 axis wrapped toolpaths now allows for the selection of wrapped geometry. Eliminate the need to unwrap the geometry first, just select it right from the solid model. You can also use the current stock to set the wrapping diameter. New unwrap controls provide a tolerance value and an arc fit option for the background calculations. You can even select whether to show the toolpath as wrapped or flat, giving you more accurate representation of wrapped toolpaths.

Trim to Stock for 4 Axis Rotary – Trim your rotary toolpath to the stock or a custom STL file to eliminate air cutting and fully optimize your rotary machining.

Revolve Stock Type – Previously only available for lathe jobs, Revolve stock type is now available for all CAM jobs in the Stock Wizard to allow you to define stock geometry by revolving a wireframe chain.

Workpiece Selection for Simulation – Assign workpiece geometry to determine exactly what geometry displays in the simulation window, regardless of how much geometry is visible in the workspace. You can assign workpiece geometry during the job setup or by using the workpiece in the CAM Tree. This works to streamline your simulation and simply the process of comparing cut stock to the workpiece for files with more than one model.

Set Default Stock Transparency – This allows you to set a default stock transparency for CAM jobs. Just open the Stock Transparency dialog box, set the preferred level of transparency, and click Set Default.

New Simulation Interface – The new interface contains a ribbon style toolbar for a more modern CAD/CAM software look and feel.