Enduro-Flex and Enduro-Flex Turbo Finishing Discs

Enduro-Flex and Enduro-Flex Turbo Finishing Discs

Walter Surface Technologies (WST) announced key enhancements to its cutting edge line of flap discs branded as Enduro-Flex and Enduro-Flex Turbo for metal finishing applications, earning high marks in finishing performance, removal rate and cost efficiency.

Walter Surface Technologies (WST) announced key enhancements to its cutting edge line of flap discs branded as Enduro-Flex and Enduro-Flex Turbo for metal finishing applications, earning high marks in finishing performance, removal rate and cost efficiency.

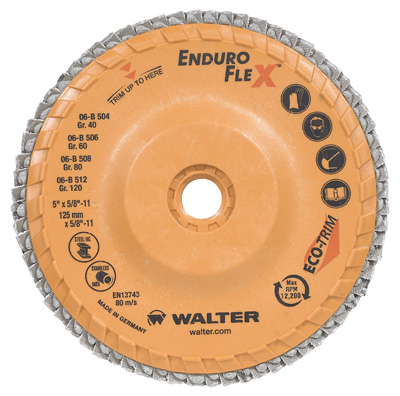

ENDURO-FLEX is now an eco-friendly alternative. When it comes to the metal fabricating and finishing industry, having high performance and being eco-friendly are no longer mutually exclusive. In addition to being the highest performing finishing discs on the market, the best selling Enduro-Flex now foregoes the traditional plastic backing and has been improved with an innovative ECO-TRIM backing made from a base of natural and sustainable plant fibers. In 2013, Walter will manufacture millions of Enduro-Flex flap discs with the new backing, helping to dramatically reduce plastic production output. Using less plastic reflects Walter's clear commitment to reducing the overall ecological footprint. A percentage of Enduro-Flex sales will go to funding the planting of new trees to regenerate forests for future generations.

Designed as a solution for finishing steel and stainless steel, Enduro-Flex flap discs require fewer changeovers, which help reduce waste and ensure greater operational efficiency. In comparative tests between flap discs, Enduro-Flex set the industry standard with 130 per cent more steel removed than leading competition. This saves both time and costs while simultaneously providing an environmentally sound solution. A 5-inch disc with Grit 40 removes up to 2,500 grams over its lifespan; performance is comparable in other Walter disc sizes and different grit sizes.