Palbit by Toolmex Facemills

Palbit by Toolmex Facemills

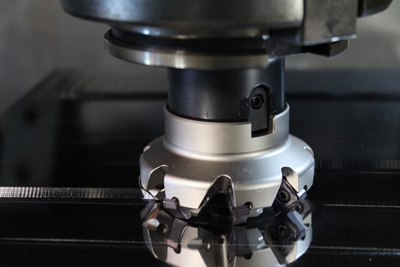

Palbit by Toolmex 45°Face mill cutters have eight 45-degree cutting edges, which create superb surface finishes with high feed rates along with large chip gullets ensuring great chip evacuation.

Palbit by Toolmex 45° Face mill cutters have eight 45-degree cutting edges, which create superb surface finishes with high feed rates along with large chip gullets ensuring great chip evacuation. All of the cutters are nickel plated and have an internal coolant supply up to five inches in diameter. The related inserts utilize double sided technologies which have high rake angles allowing a positive cutting action on the tool for lower cutting forces.

Palbit by Toolmex PH6920 has submicron Tungsten Carbide grain for enhanced toughness and wear resistance. It is coated with an advanced PVD TiAlN for extended tool life in steel, stainless steels, high temperature alloys, and irons. The coating-substrate combination provides a wide speed range in almost every workpiece material without sacrificing tool life.

Venture Machine & Tool Inc. of Onalaska, Wis., a full service design and production tooling company is using many cutters from the Palbit by Toolmex product mix including the SNH 45 — Double sided eight cornered 45°Face mill, WNM — High feed face mill, AP90 10mm and 16mm cutters and SCI 3X Drilling System. One common thing in the entire milling production is the Palbit by Toolmex PH6920 grade.

This grade has high performance levels in cutting most any material, Brian Atkinson, Tool Room Machinist from Venture Machine stated, "the Palbit cutters can take anything you can throw at them." Venture Machines is a tool and die shop and therefore face some challenging tool steels along with most any other material you can think of to complete fixturing and tooling that go into their finished products.

Venture Machine prefers the simplicity of the Palbit by Toolmex SCI drilling system because the same insert can be used in both the inboard and outboard pocket which is a time and money saver.

The previous cutters that Venture was using had eight inserts but only cutting on two, and the inserts were constantly breaking. The product did not sit in the pockets very well resulting in premature insert wear and lots of failure. Palbit SNH 45°Face mills are designed with innovative strong pockets for better accuracy allowing the inserts to better sit in the pockets. The product design allows you to flip the inserts over and use the insert again.