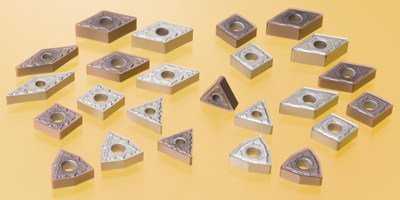

EEG and EEF Chipbreakers

EEG and EEF Chipbreakers

Sumitomo Electric Carbide Inc. has expanded its lineup to include EEG and EEF Chipbreakers for exotics and stainless steel alloys.

Sumitomo Electric Carbide Inc. has expanded its lineup to include EEG and EEF Chipbreakers for exotics and stainless steel alloys.

Designed for roughing applications, the EEG Chipbreaker features ball-shaped projection breakers for enhanced chip control. A two-step cutting edge at the front of this general-purpose breaker reduces crater wear and produces a superior surface finish when machining exotics and stainless steel alloys. The EEG performs with high wear resistance and chip control, reducing lead-time and increasing productivity.

The EEF Chipbreaker has been developed and thoroughly tested for high chip control during finishing operations. A unique slot on the rake face reduces heat generation and extends tool life, while a 20°Cutting edge reduces wear.