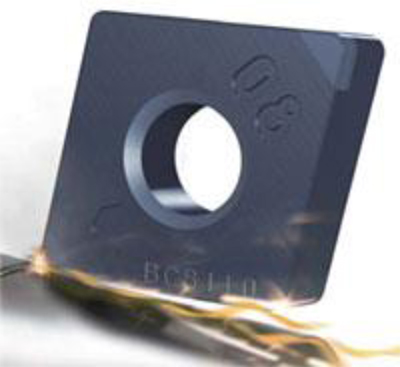

BC8100 PCBN-Grade Inserts

BC8100 PCBN-Grade Inserts

Mitsubishi Materials announces the expansion of BC8110 coated PCBN grade for high-hardened steel turning.

Mitsubishi Materials announces the expansion of BC8110 coated PCBN grade for high-hardened steel turning.

Technical Information:

• 38 new inserts to include positive style and negative style inserts.

• Honing styles include FS2-FS3 and GS2-GS3 for optimal performance.

• Longer tool life with PVD coating, when turning hardened steels.

• Coated with a new TiAlSiN technology for excellent wear resistance.

• The Ultra Micro-particle binder in the body is designed to prevent sudden fracture.

• Optimized cBN grain size and cBN content increases wear resistance and edge toughness.

Applications to Target:

• Best used with hardened steel.

• Covers the wide application range for continuous cutting of hardened steel.

• A variety of hones to maximize efficiency and tool life performance.

Benefits:

• TiAlSiN technology prevents coating exfoliation to reduce unusual wear.

• Can be used with and without coolant.