KipwareM and KipwareT

KipwareM and KipwareT

Kentech Inc. announces the release of our new and enhanced versions of its KipwareM and KipwareT Conversational CNC Programming Software for Milling and Turning.

Kentech Inc. announces the release of our new and enhanced versions of its KipwareM and KipwareT Conversational CNC Programming Software for Milling and Turning. Since its initial release back in 1999, Kipware conversational has allowed hundreds of shop floors to realize more efficient workflow by allowing non-CAD/CAM proficient chipmakers the opportunity to join in the programming process Kipware conversational was created upon the realization that the 95 percent of shop floor programming performed everyday in the real world, simple milling, drilling, turning, threading, grooving … does not require a CAD/CAM system nor a CAD/CAM programmer.

The addition of Kipware conversational allows shops to focus their CAD/CAM personnel on the more complex workpieces while the everyday programming is accomplished quickly and easily. With shops finding a shortage of skilled metalworking and CAD/CAM personnel, the use of Kipware conversational eases the programming burden and increases work flow. Building on customer feedback and "wish lists," the new versions of KipwareM and KipwareT really bring conversational programming to the next level with new features and enhancements built in a state-of-the-art user interface.

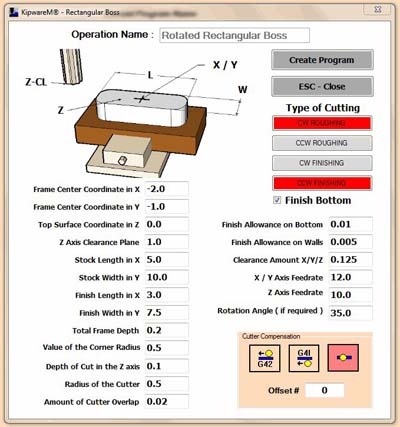

Using the power of Microsof's new .NET Version 4 Framework, the new Kipware conversational employs a vastly new and improved user interface built on the latest technology for the future. Any standard shape cycle created using Kipware's conversational, fill-in-the-blank forms can now be recalled and will appear once again in the conversational form. That means no G code experience is required as all program editing can now be done through the conversational menus. Users can have cycles created in the conversational menus auto-rotated to any user-defined angle by simply inputting it into the rotation angle field. Even TEXT/ENGRAVING can be autorotated at any angle. Users can easily LOAD previously created cycles from disk, EDIT them in the conversational menus, COPY cycles and quickly and easily edit them to create completely new cycles. These features mean faster programming and less redundant programming for items like family of parts or for re-ocurring shapes and features. New menus include both roughing and/or finishing in one menu. No need to program a roughing cycle then a finishing cycle; everything can now be done in one menu.

Users can select CW or CCW cutting for all milling cycles and can elect turning or facing type cutting for turning cycles. Individual directions can be selected for both roughing and finishing. For example, select CW for roughing and CCW for finishing or facing for roughing and turning for finishing. When finishing is selected for any conversational cycl the cutter compensation option can be selected and will be included automatically by KipwareM or KipwareT which will calculate and determine the start up move and include it in the finishing cycle. Drilling menus have been vastly redesigned and improved for faster and easier data entry and much greater flexibility.

Using the vastly enhanced KipwareTP option, users can select to plot an individual cycle or all the cycles in the Program Tree right from within KipwareM or KipwareT as the program is being created. For programming that does not fit into the "standard" shape conversational menu, users can use the included CAD like Kipware SketchPad to draw the desired toolpath or import a DXF file and create the G code through a conversational menu.