Seal-ready Surfaces

Seal-ready Surfaces

The proliferation of aluminum in the automotive sector continues to surge. Once rare, aluminum components now can account for 30% of a vehicle's weight.

The proliferation of aluminum in the automotive sector continues to surge. Not long ago, aluminum components were rare; now, they can make up 30% of a vehicle's weight. From engine blocks and gearbox housings to oil pans and battery racks, many of these aluminum components require exact roughness and crosshatch patterns to provide proper surfaces for gasket and sealant adhesion. Seemingly miniscule differentials in surface topography —also known as framed roughness — can affect the ability of sealants to adhere, impacting the quality of the seal and, ultimately, the viability of the entire part.

Meeting strict surface roughness guidelines in aluminum requires precise measurement, a careful machining approach and cutting tools optimized for the task. The right combination of these key elements can boost machine shop productivity while producing reliable, gasket- grade components.

To guide you down that path, here are six steps that will help you achieve a gasket-grade surface finish in aluminum.

1. Measure roughness correctly

Most manufacturers have in-house measuring devices that can provide accurate Ra (arithmetical mean roughness) and Rz (mean roughness depth) values. Use them. Even experienced machinists should not rely on their eyes or fingertips where surface topography is concerned. Throughout the machining process, verify the framed roughness with precision instruments to promote long-term component dependability.

2. Program to reduce smear

When an indexable milling tool first enters the material, it can create an irregular, unintentional "smear" if not executed carefully. The same risk holds for the cutting tool's exit path. These smears present hazards to the roughness profile and the overall integrity of the component by forming pockets where oil or fluid can pool. Programming a slight taper into the cutting path or beginning each pass with the back side of the cutter can mitigate these risks. Work with your tooling provider to determine the proper programming techniques for your tool and the component in question.

3. Get creative with coolant

In automotive applications — especially in the electric vehicle space — coolant-free machining is becoming commonplace for components like battery trays, where even a small amount of coolant residue can lead to problems downstream. Properly cooling the cutting zone will lead to a more precise roughness profile while also helping to control chips and reduce burrs. Instead of standard coolant, consider using minimum quantity lubrication (MQL) — or even pressurized air — in battery-facing components to keep the surface at a workable temperature.

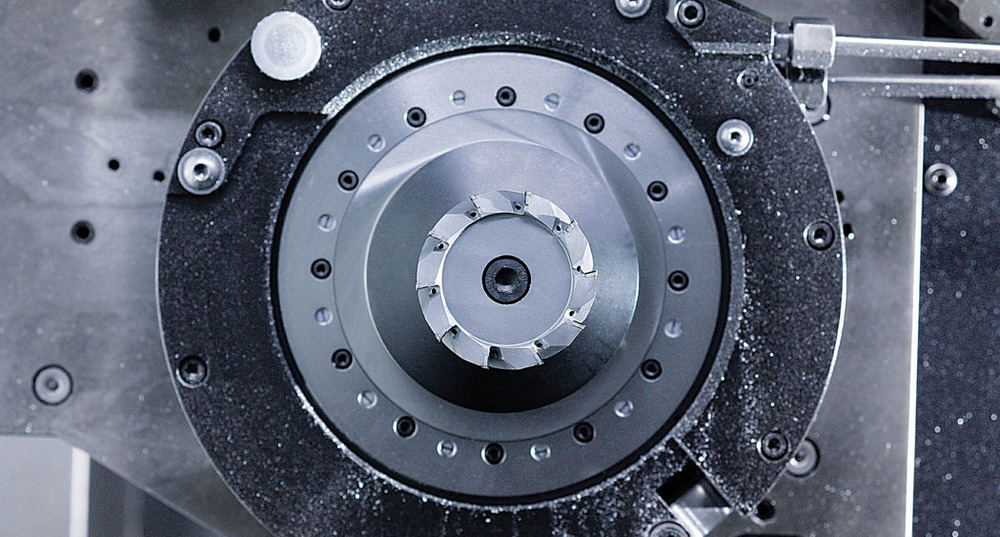

4. Leverage a specialized cutter

Component production order size and time constraints can dictate which cutting tool is ideal for the job. For small batches or prototypes, an off-the-shelf, square-shoulder indexable face mill made with polycrystalline diamond (PCD) material will suffice. In high-volume scenarios, opt for a more optimized rotary broach tool capable of creating scratch surfaces at faster cycle times.

Additionally, while many machinists intuitively gravitate toward a smaller cutter, consider utilizing a larger cutter body. Larger tools may slightly increase cycle time, but they more than compensate by providing better control, reducing errors and creating a more uniform surface finish.

5. Deploy a mixed-insert solution

Making use of each pocket where inserts slot into the cutting tool head can streamline the scratching process. For example, a manufacturer might use general-purpose PCD inserts in nine of the 10 pockets in the tool head, and a special scratching insert with a slightly different geometry in the remaining pocket. Alternatively, dropping a wiper insert 10 μm to 20 μm below a scratching insert (or vice versa) can give the component its trademark shine while the roughness profile is being shaped. These techniques can create ideal surface topography in fewer passes. Remember that aluminum with high silica content or other additives can be hard on cutting tools, so select your inserts accordingly.

6. Partner with a qualified tool provider

At every stage of the machining process, whether roughing or finishing, the right tooling partner can provide guidance and recommendations for the proper cutting heads, inserts and grades, coatings and geometries, and even toolpaths. These insights can translate to real cost and time savings on the shop floor, optimizing production while ensuring the gasket finish meets exact roughness specifications.