Turning To Surface Quality Optimization

Turning To Surface Quality Optimization

This article covers the fundamental principles of surface roughness and presents several tips proven to enhance surface quality in turning operations.n

This article covers the fundamental principles of surface roughness and presents several tips proven to enhance surface quality in turning operations.

Understanding Surface Quality

Surface quality, commonly referred to as surface roughness, provides a numerical value representing how smooth a surface appears. This measurement can be challenging since it converts a three-dimensional visual characteristic into a single numerical value.

Three primary approaches exist for obtaining surface roughness measurements.

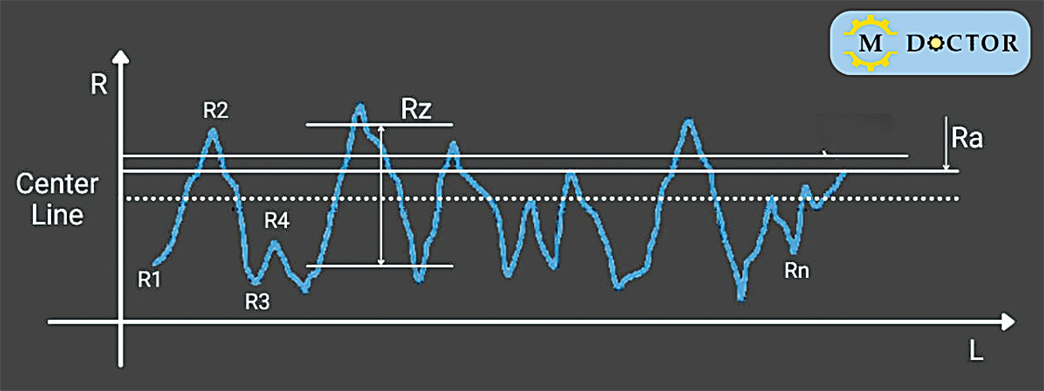

- Mechanical Scanning: The most widely employed technique for measuring surface quality involves scanning the surface using a stylus that documents the microscopic peaks and valleys across a linear path. This measurement generates a profile (see Surface Finish Scan chart below) that undergoes mathematical analysis to produce a surface quality value.

- Visual Assessment: An older conventional approach involves comparing a surface visually against a reference set of various surface quality standards using human observation.

- Optical Digital Scanning: A high-resolution digital camera linked to a computer conducts an optical examination of a surface area and computes the surface quality.

Surface Finish Scan

Surface Finish Scan Surface Quality Measurement Units

Multiple units exist for measuring surface quality, with Ra and Rz being the most widely used. Given the frequent confusion between these units, let's clarify their differences.

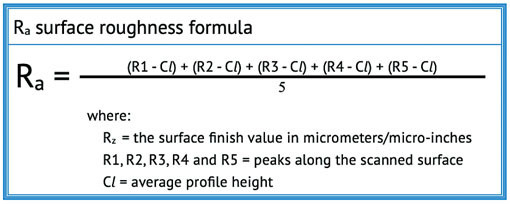

Ra, known as the roughness average, is the most frequently used unit. According to ASME B46.1, Ra represents the arithmetic mean of the absolute values of profile height variations from the centerline, measured within the evaluation length. Using the same parameters that correspond with those shown in the Surface Finish Scan chart, the calculation follows the formula shown above.

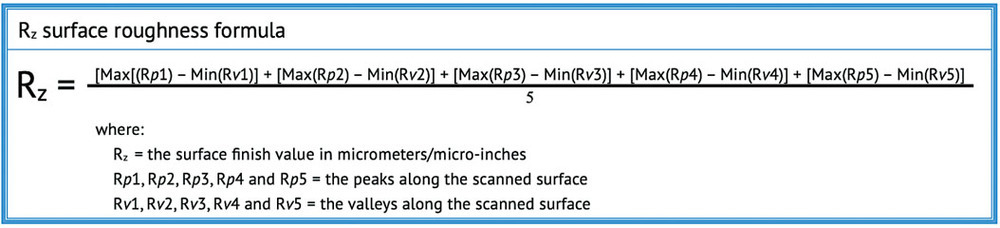

Rz, is the "Peak to Valley" average, and is the second most common unit. The calculation involves measuring the vertical distance between the highest peak and the lowest valley within the scanned profile. The top five peaks and the five deepest valleys are measured, and then these distances are averaged. Rz consistently produces higher values than Ra. The calculation uses the formula shown below.

A frequent question from machinists and engineers concerns the conversion of Ra to Rz values. Direct conversion from Ra to Rz (or Rz to Ra) is impossible since they represent different characteristics.

This would be like asking, "How can I convert height to weight?" Height cannot be converted directly to weight, but rough estimations based on statistical data are possible. For example, you can say with 99% probability that a 6-foot-tall person typically weighs between 140 and 290 pounds. Weights of 100 or 400 pounds would be highly unlikely.

For Ra to Rz conversions or vice versa, statistical analysis enables a reasonable prediction of the Rz range for a specific Ra value. You can use conversion charts or an online Ra/Rz conversion tool.

Having covered the fundamentals, let's examine methods for enhancing surface quality in turning operations.

The Surface Quality Formula and Key Insights

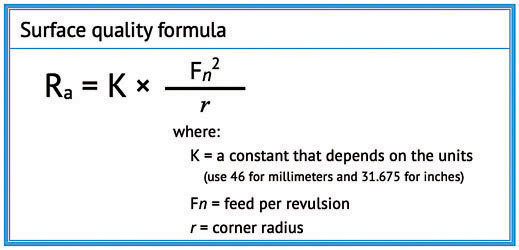

Understanding the best course of action begins with familiarizing yourself with the surface quality formula.

Analyzing this formula reveals three interesting observations.

- Reducing the feed rate enhances surface quality.

- A larger corner radius improves surface quality.

- Since the radius is squared in the formula, it is a much more influential parameter for optimization.

Experiment with this equation using the Surface Quality Calculator on the Machining Doctor website.

Workholding

Solid clamping of the workpiece and cutting tool is critical for achieving a proper surface finish. If either is done incorrectly, optimizing the feed and corner radius will be ineffective.

When surface quality takes priority, ensure you use a premium power chuck with quality jaws. Further improvement involves grinding the jaws to match the blank diameter. This increases the contact area between the clamping mechanism and the workpiece and reduces runout.

Following proper workpiece clamping, the next step is stabilizing the cutting tool.

- Employ Capto (ISO 26623) shanks or similar advanced clamping systems for external tools while avoiding conventional square shanks.

- Utilize slotted, shrinking sleeves for internal tools rather than traditional direct screw clamping.

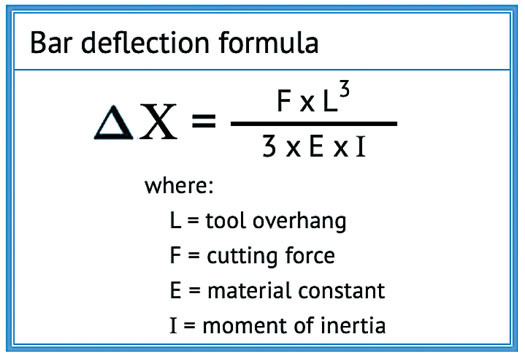

- For both external and internal tools, minimize the overhang. Even small overhang reductions can substantially affect system rigidity. The bar deflection formula (below) shows that deflection correlates directly with overhang cubed.

Additional Recommendations

- Choose a sharper (ground) cutting edge.

- Higher (positive) peripheral and top rake angles reduce workpiece pressure, thereby minimizing vibrations and enhancing surface quality.

- Try to avoid Build-Up-Edge. Once BUE develops, other optimization steps become ineffective. Typically, increasing cutting speed addresses this issue. Alternative solutions include testing different carbide grades and employing sharper edges.

- Choose an appropriate chip breaker to direct chips away from the workpiece (preventing surface scratching).

Optimal results never come from improving a single factor alone. Achieving good results demands a systematic approach that addresses as many factors as possible.