Understanding Hardness

Understanding Hardness

Hardness impacts machining decisions. This guide compares Rockwell, Brinell, Vickers, and the tools needed for hard materials.

What is Hardness?

Hardness defines a material's ability to withstand localized plastic deformation due to mechanical force or abrasion, quantifying how resistant a surface is to dents or scratches. A harder material is stronger, but increased hardness increases brittleness, making the material more sensitive to cracking under load. This property significantly affects material selection and impacts mechanical behavior, longevity and manufacturing costs. In machining applications, knowing the hardness of the workpiece material is crucial — it directly impacts tool selection, carbide grades and optimal cutting conditions, which we'll discuss in this article.

![Brinell [HB]](https://images-cdn.dashdigital.com/cuttingtoolengineering/junejuly_2025/data/articles/./img/013-01.jpg)

![Vickers [HV]](https://images-cdn.dashdigital.com/cuttingtoolengineering/junejuly_2025/data/articles/./img/013-02.jpg)

Units for Measuring Hardness

There are several established methods and corresponding units used to measure hardness. The Rockwell, Brinell and Vickers scales are the most common in machining. Below, we outline each method, explain the application of each, and learn how to convert them from one to another.

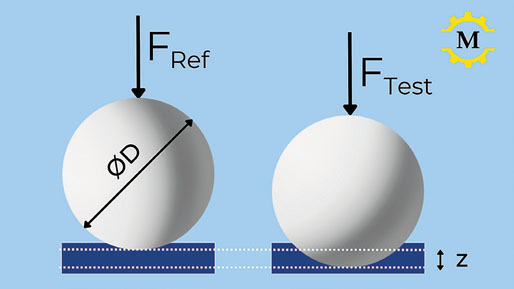

Rockwell (HRC/HRB/HRA): Rockwell is the most frequently used unit in engineering drawings. The test compares penetration depth from a large load against a minor preload using a spherical indenter. It consists of nine scales labeled A through K, each employing different forces and ball sizes. The Rockwell C scale (HRC) is the standard for most metallic workpieces in machining, typically falling between 10 and 65 HRC.

Brinell [HB]: The Brinell hardness scale is the most common unit used to measure the hardness of machined raw materials. (For example, in cutting condition tables in the supplier's catalogs). This method uses a 10 mm steel ball with a force of 3,000 kgf (6,614 lbf). Figures for machined metals usually range from 100 HB for softer materials to 650 HB for hardened steels. The Rockwell C scale is only valid for materials above 180 HB; for softer metals, Rockwell B is used. Brinell, however, provides a continuous scale across the entire range.

Vickers [HV]: The Vickers system is typically used to describe cutting material hardness, like carbide grades, ceramics, CBN and PCD. The test uses a diamond-shaped pyramid, and the HV value results from dividing the applied load by the indentation's surface area. Carbide typically falls between 1,300 – 1,900 HV. Ceramics reach 2,000 HV, CBN up to 3,000 HV, and PCD as high as 6,000 HV.

Hardness Conversion

A universal formula for converting between different hardness scales does not exist. Instead, conversion tables are used. In modern practice, online conversion tools have gained popularity due to their speed and simplicity. Users can simply input a value in one hardness scale and select the desired unit, and the tool will provide the equivalent hardness value.

Hardness in Machining

Hardness significantly influences machining operations. It affects tool life, power consumption, and removal rates, making it essential to consider both workpiece and tool hardness.

Workpiece Materials

It might appear that softer materials are easier to machine, but very soft metals become problematic. They often cause material buildup on the cutting edge (BUE) and challenging chip control, particularly below 180 HB. On the other hand, increasing hardness beyond a certain point accelerates tool wear, reducing cutting speeds and tool life. The optimal machining zone generally starts around 200 HB (or 15 HRC). Beyond a certain threshold, using a conventional carbide insert to machine the material becomes nearly impossible. Advanced materials such as ceramics and CBN (Cubic Boron Nitride) become necessary.

Tooling Materials

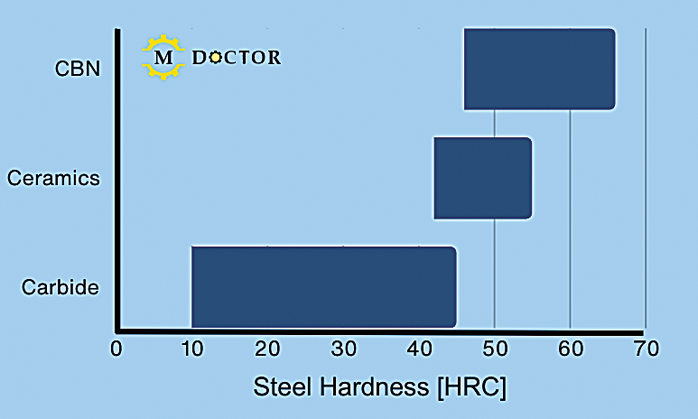

The Steel Hardness chart categorizes the recommended cutting material to machine ferrous metals depending on their hardness level.

Tungsten Carbide: Tungsten Carbide is the base material for most modern cutting tools. Workpiece hardness typically ranges from 12 – 45 HRC (180 – 450 HV), and carbide grades lie between 1,300 and 2,000 HV. While higher hardness grades can handle more demanding applications, they are also more brittle and less tough, increasing the risk of edge fracture. Choosing the appropriate grade is a broad topic that deserves its own discussion.

After heat treatment, some alloys can reach a hardness of up to 65 HRC (950 HV). Advanced cutting materials are necessary to handle this.

Ceramics: Ceramic inserts, made from Al2O3 or Si34, provide a hardness range of 2,100 – 2,500 HV — about 40% higher than carbide. It allows effective machining of steels up to 55 HRC.

CBN: Polycrystalline Cubic Boron Nitride (PCBN or CBN) has a high hardness of around 4,500 HV. With excellent thermal and chemical stability, CBN is suitable for steels up to 70 HRC and other challenging materials.