Increase feed rate or depth of cut?

Increase feed rate or depth of cut?

The Grinding Doc says it depends on what your biggest issue is: thermal damage, chatter or excessive wheel wear

Dear Doc: We surface-grind, and there's disagreement at the shop. When increasing stock removal, is it better to increase the feed rate or the depth of cut?

The Doc replies: The answer is the always popular "It depends." It depends on what's your biggest issue, as in "If I keep pushing it, what am I most worried about: thermal damage, chatter or excessive wheel wear?"

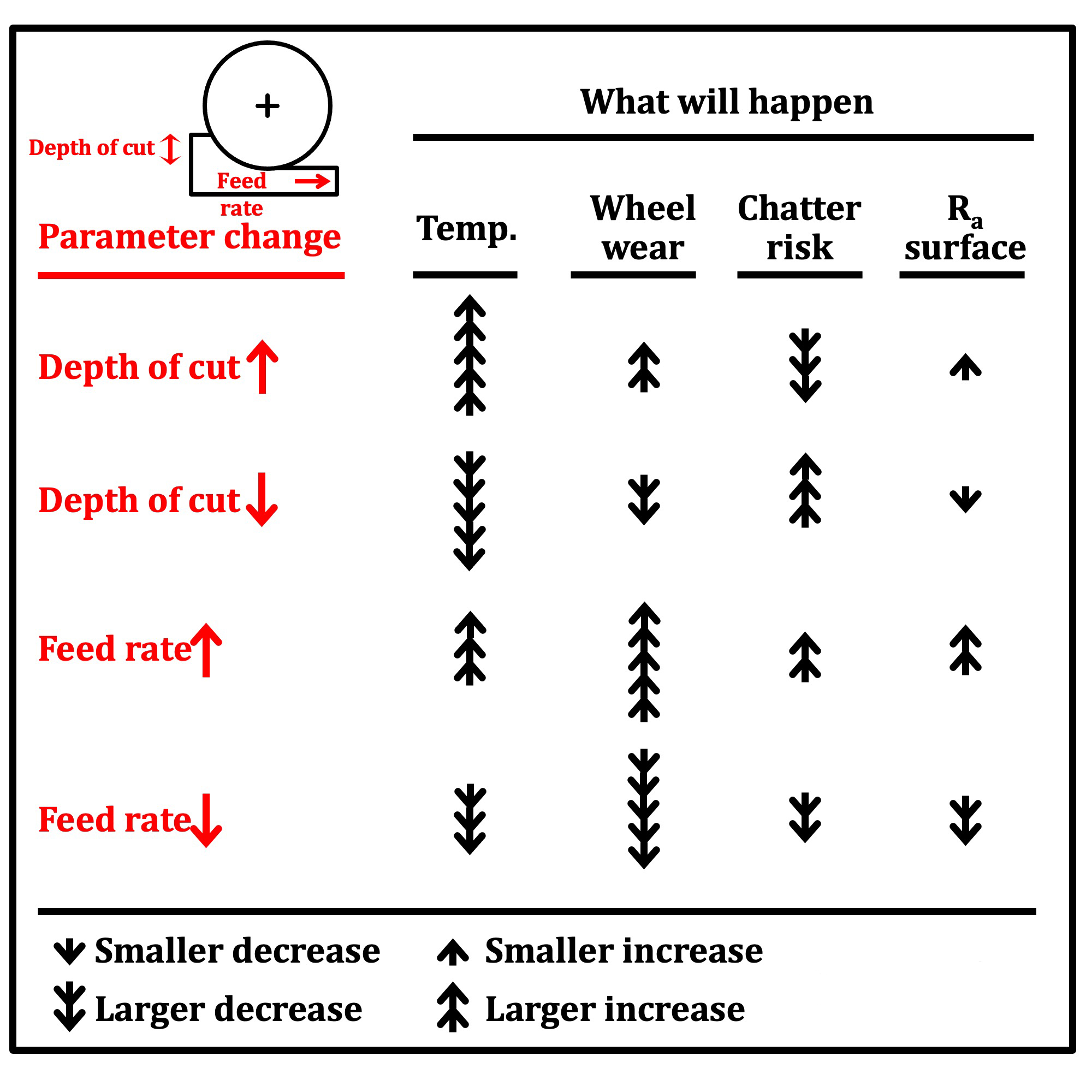

If your main problem is grinding burn, increase the feed rate, or table speed. Temperatures will increase but not as much as if you increase the DOC. If your principal concern is chatter, increase the DOC. If your biggest issue is wheel wear, increase your DOC.

All this is for a fixed wheel speed. But for major improvements, I'd prefer that you take my course and learn the concepts of Q-prime and aggressiveness and how to use The Grinder's Toolbox to manipulate multiple parameters at once (DOC, feed rate and wheel speed). Also, some of these differences are small, and some are large. For example, increasing your feed rate will increase your temperature somewhat but increase your wheel wear a lot. The figure shows relative values.

Dear Doc: We use both resin-bonded and electroplated CBN wheels. When mounting a new wheel, do we need to "tap in" the wheel to minimize runout or just mount the wheel and start running?

The Doc replies: For resin-bonded wheels, tapping in is usually not necessary. After mounting, the wheel will be eccentric because the wheel bore diameter is larger than the shaft diameter — that is, there is "play." That's not a problem. Dressing removes that eccentricity and almost all the imbalance associated with it. When you go to grind, you won't be banging on the high point of the wheel.

But with electroplated wheels, you never dress. Therefore, any eccentricity after mounting — there's always eccentricity — will cause the wheel to bang on the high point until it wears away. If there's a lot of eccentricity, you might bang for weeks before the high point is removed, which means possible chatter and more wheel wear. So mount a dial gauge and tap away that eccentricity the best you can. You'll never make it perfect, but you'll make it better. And better might just increase your electroplated wheel life from two months to 12 months.