What is a Collet? Types, Uses, and Design Explained

What is a Collet? Types, Uses, and Design Explained

Discover the essential guide to collets: what they are, how they work, their types, and maintenance. Learn about collet applications, advantages, and comparisons to other toolholding systems.

Collets are among the most commonly found items in machine shops. However, even professionals who routinely use these toolholding mainstays may not know all the critical details about them.

This article dives into the intricacies of collets — from their design and types to how they compare with other toolholding options. It also covers the latest advancements in collet technology and provides tips for choosing and using collets to extend their lifespan and improve machining results.

How Does a Collet Work?

Placed in a chuck, a collet forms a collar around the tool or workpiece. The ER collet, the most widely used tool-clamping option, exerts clamping force through compression when tightened with a nut. ER collets are commonly used to hold tools like endmills, drills, taps, and reamers.

Comparing Collets to Other Toolholding Systems

Shrink-Fit Holders vs. ER Collets

Shrink-fit holders are designed for precision but come with limitations:

- Each holder is tailored for a specific tool diameter, requiring multiple holders for different tools.

- Shrink-fit systems also need a heating unit for tool installation, adding cost and complexity.

In contrast, ER collets are more versatile, as one holder can accommodate a variety of tool shank sizes.

Hydraulic and Milling Chucks

Hydraulic and milling chucks allow for straight reduction collets to adjust tool sizes. However, their performance is reduced compared to ER collets due to increased runout and decreased clamping force.

The Versatility of ER Collets

Alan Miller, engineering manager at BIG KAISER Precision Tooling Inc., explained that the main advantage of ER collets is their versatility. For example, an ER32 collet chuck can hold tool shanks ranging from 3.175 mm (0.125") to 19.05 mm (0.75") by simply swapping out collets.

ER collets offer compression flexibility but have limitations. Andy Moon, product manager for milling and toolholders at Guhring Inc., noted that this flexibility is limited to a small range — typically between 0.5 mm (0.02") and 1 mm.

When to Avoid ER Collets

ER collets are not ideal for high-torque cutting. Their compressibility, which provides flexibility, also introduces runout and instability, making them less suitable for heavy-duty machining.

"For high-performance applications, especially in milling, I generally steer people away from an ER collet chuck," Moon said.

However, for light milling or finishing tasks, ER collets remain an excellent choice. Matching collet size to the tool shank diameter is critical for optimal performance.

Innovations in Collet Technology

FPC Collets

Emuge Corp.'s FPC collets are designed for precision with minimal flexibility. They conform to ISO H6-H9 standards and fit one specific tool diameter. The newly introduced Slim Line models address challenges in confined workspaces, especially for five-axis machining.

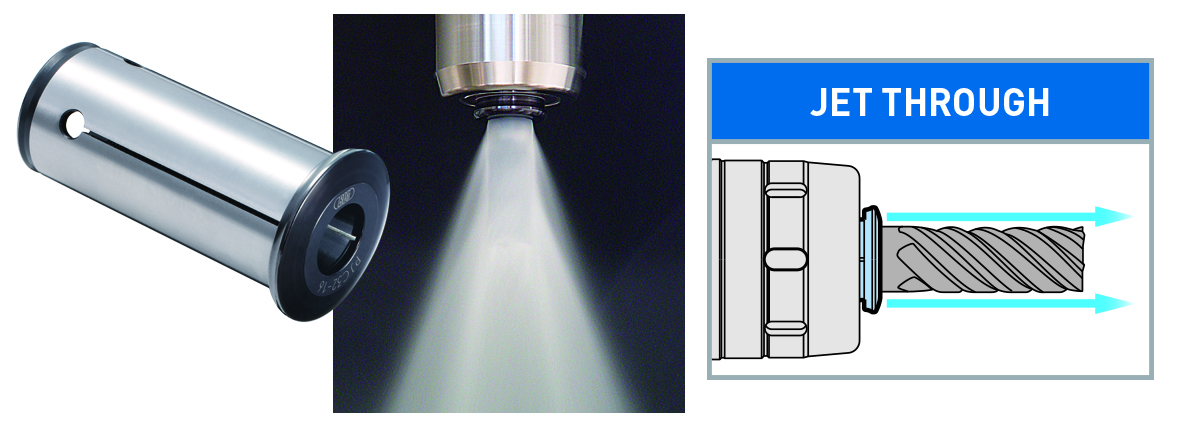

BIG KAISER's Perfect Seal and Perfect Jet Collets

BIG KAISER Precision Tooling introduced Perfect Seal and Perfect Jet collets for hydraulic chucks:

- Perfect Seal: Seals the tool shank to allow high-pressure coolant flow.

- Perfect Jet: Improves coolant delivery along the tool shaft by reducing clearance between the collet and tool.

Best Practices for Collet Maintenance

Proper maintenance can significantly extend the life of collets and improve machining results. Here are some do's and don'ts:

Do's

- Clean Regularly: Use an air hose to remove debris from the collet and chuck during tool changes.

- Inspect Visually: Discard any collets or toolholders showing signs of wear or damage.

- Match Sizes: Always use a collet size that matches the tool shank diameter.

Don'ts

- Don't Over-Tighten: Excessive tightening can stress and deform the collet and nut.

- Don't Overextend Tools: Avoid pushing tools too far out of the holder, as this reduces gripping force and stability.

FAQs About Collets

What is a Collet Used For?

Collets are used for securely holding tools or workpieces in machining tasks, such as milling, drilling, and reaming.

What are the Different Types of Collets?

Types include ER collets, FPC collets, shrink-fit holders, and hydraulic chucks, each with unique strengths and applications.

How Do I Choose the Right Collet?

Base your choice on tool size, required clamping force, and machining application. ER collets are versatile, while hydraulic and shrink-fit chucks are better for precision work.