‘Recipes’ to help machinists

‘Recipes’ to help machinists

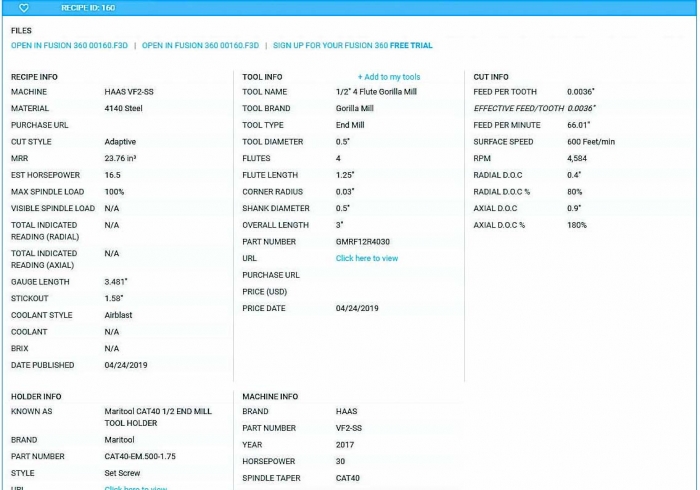

ProvenCut offers tested speeds and feeds backed by video tutorials and comprehensive machining and tool information.

Properly machining a part requires knowing the correct speeds and feed rates for a cutting tool and workpiece material — a skill that can take years to master. What if a resource existed that could make it possible for anyone to run a CNC machine and successfully cut a range of materials, from plastic and stainless steel to titanium? What if the same resource could help seasoned machinists learn how to optimize a new cutting tool or material?

More than a decade ago, I bought a benchtop CNC mill to develop a product. To improve the odds of my business succeeding, I needed to learn the basics of machining. But all the essentials, such as cutting tools and CAD/CAM software, were foreign topics to me. So I soaked up every resource I could find in the pre-YouTube era and fell in love with machining.

A partial recipe from ProvenCut. Images courtesy of J. Saunders

Each ProvenCut recipe includes, among other ingredients, a photo of the chips made during the cut

Countless aids since have emerged that shorten the learning curve for manufacturing entrepreneurs: affordable CAD/CAM software; YouTube channels dedicated to CNC machining, including my company's own, NYC CNC; online and hands-on training classes; and the resurgence of manufacturing through reshoring and insourcing. Yet I have continued to see people struggle with speeds and feeds whether they are new to machining, working with a new material or trying to optimize a new cutting tool.

The machining world needed a modern solution for determining correct speeds and feeds — a solution that accounted for high-speed CAM toolpath strategies, current CNC machine capabilities and user-friendly, intelligent interfaces. The idea for ProvenCut was born. It would offer proven speeds and feeds backed by video tutorials and comprehensive machining and tool information.

Since launching ProvenCut last year, user response has been exceptional, with feedback ranging from "You saved me hours of testing a new tool for stainless steel" to "ProvenCut is like watching high-definition TV after spending your whole life reading plain text."

Each ProvenCut recipe includes:

- Comprehensive cutting data, ranging from coolant and gauge length to horsepower.

- Video footage of the cut, allowing users to watch and listen as if standing next to a skilled machinist.

- Photographs of the cutting tool, the chips made during the cut and the machine setup.

- Links to purchase tools, toolholders and raw material.

- A link to automatically open the cutting tool and CAM operation in Fusion 360 software from Autodesk Inc.

ProvenCut recipes can be filtered by almost any machining criteria. Examples include the machine tool brand; gauge length; number of flutes on a tool; coolant type, such as flood, through the spindle, dry or near dry; machine horsepower; toolholder style; and tool type. The filter options are unparalleled in the speeds-and-feeds world when compared with resources like tool manufacturers' starting recommendations, PDF guides and calculators.

Each ProvenCut recipe includes, among other ingredients, a photo of the chips made during the cut. Image courtesy of J. Saunders

Dimensional units may be switched from imperial to metric with a master toggle, or a simple mouse hover over any dimension will display the alternate unit. Recipes can be starred as favorites, and users can add cutting tools to their tool libraries to filter recipe results by cutting tools that they already own.

Recipes are created at Saunders Machine Works LLC, which operates over a dozen CNC machines that range from a FANUC Robodrill to a Haas UMC-750. Our experience running NYC CNC, a CNC YouTube channel with more than 300,000 subscribers, meant we knew how to film machines and had a great audience to help kick-start ProvenCut. ProvenCut also has worked with select partners to make recipes with machines, such as the popular Datron neo and high-end DMG Mori machines.

ProvenCut continually is expanding its CNC machines, recipes and materials, as well as adding different CNC machines, including lathes and turning centers, as we reduce barriers and allow anyone to succeed with CNC machining.