The FOGS HD can rough and finish precisely

The FOGS HD can rough and finish precisely

Machine Technology: Starrag offers the first heavy-duty machine capable of meeting the most stringent precision requirements.

One would expect an extra-large machine tool to be used for roughing. But it's surprising when a big machine also is capable of a lighter touch to finish big parts that have demanding precision requirements.

So the combination of heavy-duty roughing and high-precision finishing capabilities was the news in the introduction of the Droop+Rein FOGS HD (heavy-duty) vertical machining center from Starrag. A 5-axis machine in its standard configuration, the FOGS HD features a moving overhead gantry. The gantry, equipped with the milling head, moves in the lengthwise direction over a large stationary table holding the part. This distinguishes the machine from portal-type machine tools, which have moving tables.

The FOGS HD is also modular, allowing the machine to be supplied with a variety of milling heads (over 300 different styles and ratings), spindles and table configurations, as well as controls and toolchangers.

When it comes to roughing, the FOGS HD offers the high power (50kW to 100kW) and high torque (2,400 to 7,500 Nm continuous) needed for efficiently processing large steel and titanium components, said Tim Mooney, Midwest sales manager for Starrag USA Inc., Hebron, Kentucky. He added that the machine has rigid hydrostatic guides in the X, Y and Z directions that boost metal-removal rates and increase output.

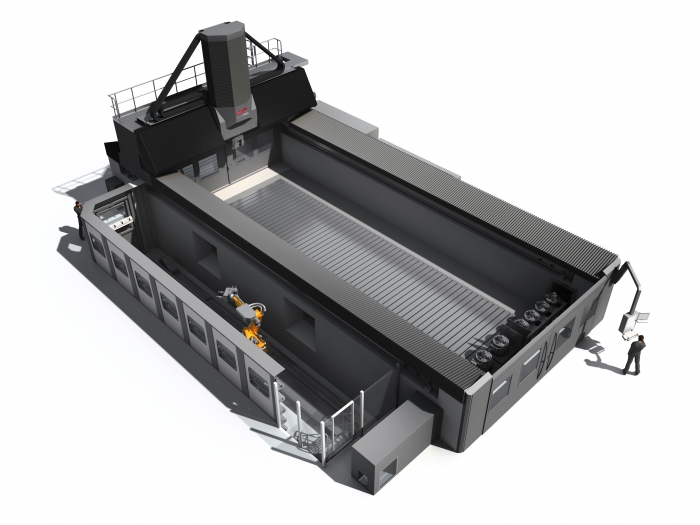

Designed for machining large components, Starrag's Droop+Rein FOGS HD vertical machining center offers both heavy-duty roughing and finishing capabilities. Image courtesy of Starrag USA

In the past, manufacturers of large parts with stringent precision requirements needed to buy both a roughing machine and a finishing machine, Mooney said. In some cases, manufacturers also needed to manually perform secondary finishing operations. Now, according to Mooney, all that these manufacturers need is the FOGS HD, which is the first heavy-duty machine that can rough and finish to meet die quality standards. "Parts come off our machines with no hand finishing required—no mismatched (edges), chatter marks or surface imperfections. That requires a very precise machine."

The precision comes from a combination of factors. For one, Mooney said, light-duty finishing machines aren't rigid enough to create a surface that requires no hand finishing. By contrast, "our structure doesn't move."

The FOGS HD also offers what Starrag calls "high dynamics" in all axes—the ability to precisely move the gantry and milling head, changing directions at exactly the right time and stopping in exactly the right spot. Seven motors combine to enhance the machine's control over the moving mass, Mooney said.

A FOGS HD machine with travel of 6m, 4m and 1.5m in the X, Y and Z directions, respectively, can achieve accuracy of approximately 50µm throughout the workspace, according to Mooney, who added that this ability meets the requirements of the U.S. Department of Defense's Joint Strike Fighter aircraft program. "I don't know of any other big machine tool that can do that."

FOGS HD configurations offer travel of 3m to 31m along the X-axis, 3m to 6m along the Y-axis and 1.5m to 2.5m along the Z-axis. Though the machines are big, Starrag reports they take up 40 percent less space than machines with a moving table.

In a moving table configuration, the milling head above the table is fixed in the lengthwise (X) direction. Therefore, the table must be able to extend to its full length on each side of the head for the cutting tool to cover the entire table length. For example, if the table is 6m long, the machine must cover at least 12m in the X direction. By contrast, the gantry of the FOGS HD can move along the X-axis over a fixed 6m-long table, eliminating the need for an extra 6m of machine length.

Starrag also reports that the FOGS HD can finish items up to 30 percent faster than a comparable portal milling machine. By eliminating the need to move parts from a roughing machine to a finishing machine, the FOGS HD eliminates an additional setup. Machining can proceed more quickly because the FOGS HD can be configured for multiple work zones. While a part is machined in one work zone, another part can be set up on the table in a different zone. In addition, the gantry can be equipped with two milling heads, so two parts can be processed simultaneously while part setup work is done in a different zone.

Possible applications for the FOGS HD include aircraft parts, mold-and-die components, locomotive diesel engines and parts for nuclear power plants—big parts that need a precise finishing touch after roughing.