Sports R&D company adds VMC

Sports R&D company adds VMC

Looking to streamline its process and improve part quality, Automated Design Corp. moved into a facility that enabled it to set up a machine shop.

Whether it's a baseball or a hockey puck, if an object moves in the world of sports, its speed must be known. That's where Automated Design Corp. enters the picture.

The Romeoville, Ill., company specializes in sports R&D testing equipment; ADC's iBeam projectile sensors are the industry standard for velocity data collection.

ADC was founded in 1986. Until recently, the company outsourced the machining of parts. ADC was sending parts to up to four machine shops, but, lately, overall part quality has been disappointing, said Joe Bitsky, vice president of business development. "We were rejecting close to 30 to 40 percent of the parts."

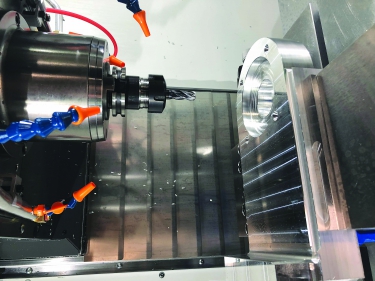

Automated Design produces a part at its machine shop

with a Basic Mill cutting tool from Haimer. Image courtesy of Automated Design

As a result, ADC had to hire a full-time QC manager to carefully inspect each outsourced part, which was accepted, returned for corrective action or rejected outright. In addition, the lead time for parts was long. Bitsky said ADC had to wait about 2 weeks to get quotes after putting out bids and then wait some more while the order came up on the vendor's schedule. Receiving an order could take up to 10 weeks, not including the time spent waiting for a rejected order to be corrected.

"We would have to drive to the machine shop or wait for the machine shop to drive here, sending parts back and forth, have discussions and wait for the parts to get into their system," Bitsky said about having parts corrected.

Looking to streamline the process and improve part quality, ADC moved into a facility last spring that enabled it to set up a machine shop. After installing a new Haas VF-2 vertical machining center the first week of January, ADC hired a machinist and began the process of tooling up the VMC, Bitsky said.

Bitsky said Drew Strauchen, vice president of Haimer USA LLC, Villa Park, Ill., is a longtime friend who was glad to provide consultation. "We were able to have some good, honest conversations with Drew about what we really needed and what he recommended."

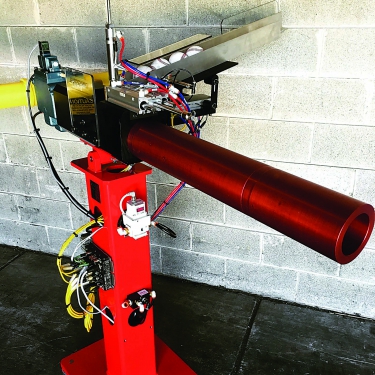

ADC Cannons, which can be mounted to a pedestal, are the basis

for numerous sports development systems. Image courtesy of Haimer USA

He added that after hearing what Strauchen had to say, ADC purchased about two dozen ER collets with 5µm precision collets and Basic Mill cutting tools from Haimer. "They are definitely more expensive than some of the other options, but we wanted to have the best tools to make the best parts with," Bitsky said. "That is our goal."

In addition to the solid-carbide cutters from Haimer, ADC applies HSS tools from other toolmakers. "We are trying to pick strong vendors in every aspect of what we do," Bitsky said. "We are a small business that leans on our vendors to assure we are getting the right products."

With everything in place, ADC began producing the required small runs, typically one or two parts, that fit within the machine's work envelope of about 20" wide × 30" long × 19" high. The workpiece materials include aluminum, stainless steel and plastic. As for outsourcing, ADC sends out only turned parts and just about a dozen other parts per quarter. The latter are outsourced because they are too long for its VMC. The company is working on redesigning those parts to produce them in-house, Bitsky said.

Despite being on a machining learning curve, the number of rejected parts has essentially dropped to zero. Parts go from the CAD system directly to the machine, cutting as much as 8 weeks off the turnaround time.

Even with every part being a good part, the person hired to manage QC still has a job, switching to assembly instead. Because quality and fit problems have largely disappeared, Bitsky said assembly time has been reduced up to 40 percent for some products.

One aspect of the machining operation Bitsky didn't expect to increase was machine utilization. "Our original plan was to use this machine about 50 percent of the time, and right now we're using it about 120 percent of the time," he said. "I just wish I had another machinist so we could operate it on two shifts."

The increase in business activity is partly due to customers who visit the shop, see ADC's new capabilities and then want to submit more projects, Bitsky said. "We are trying to present quality."