Changing workflow: Bringing work to the workpiece

Changing workflow: Bringing work to the workpiece

Picum MT, a startup at Leibniz University in Germany, is collaborating to redefine the manufacturing workflow, which traditionally has involved moving a workpiece from machine to machine or from station to station.

Since the early days of Henry Ford's assembly lines, the flow of manufacturing has moved a workpiece from machine to machine or from station to station. In the traditional job shop, that has meant a machine tool remains in place.

Developments such as CNC programming, robotics and other automation have improved and streamlined the process, making it more efficient and accurate, but have not changed the fundamental flow.

Each move of the workpiece creates downtime and setup time. Quality is challenged by potential damage to the workpiece and repositioning at each new place.

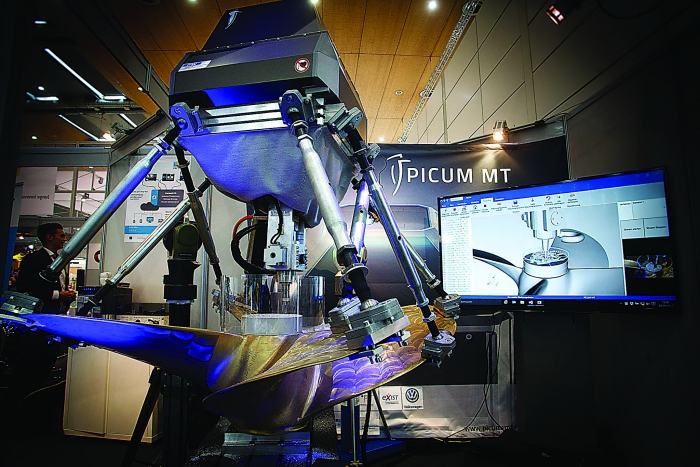

The Picum One robot that can move along components and hold on to them while drilling, milling and grinding. Image courtesy of Picum MT.

Picum MT, a startup at Leibniz University in Germany, is collaborating to redefine workflow. The team intends to incorporate the principles of Industry 4.0, which looks to automation, the cloud, the industrial internet of things and data exchange among machines to advance manufacturing processes.

According to Dominik Brouwer, Picum MT's managing partner and CEO, the company envisions a future of multiple mobile robots that can essentially crawl on workpieces—instead of the workpieces moving—and complete a broad range of manufacturing tasks.

The group's goal is to integrate modern hardware, innovative software, sensors and intelligent algorithms, Brouwer said. "The result will reduce downtime and costs while increasing flexibility."

The team's efforts have led to the Picum One, a robot that can move along parts and hold on to them while drilling, milling and grinding. The Picum One weighs about 100kg (220.5 lbs.) and can dock with any desired component. It is fitted with a 5-axis kinematic system and a 7.5kW (10 hp) milling spindle. According to Brouwer, as it moves, it can determine its position to an accuracy of 15μm.

Already, Picum MT is looking forward to working with its first customers: large German automakers. The focus will be on rapid maintenance and modification of molds for deep drawing.

"As we continue to develop the platform," Brouwer added, "we'll be able to incorporate machining modules, welding, 3D printing and measuring. Because we include the complete process chain in one machine with an integrated software solution, we will be able to cut down the time for mold maintenance work from 2 weeks to only 6 hours. That's a reduction of about 95 percent."

For more information about Picum MT, Garbsen, Germany, call +0511-762-19937 or visit www.picum-mt.com.