Overview of parts deburring

Overview of parts deburring

All shops are concerned with burrs, a natural side effect of cutting. They are all looking for a single solution to prevent or remove burrs. Unfortunately, there is no panacea.

All shops are concerned with burrs, a natural side effect of cutting. They are all looking for a single solution to prevent or remove burrs. Unfortunately, there is no panacea.

A Yaskawa Motoman PerfectEdge robot deburrs gears up to 20" in diameter and 10" tall. Image courtesy of Yaskawa Motoman.

However, major improvements can be made. The basic requirements are simple:

- Keep burrs small.

- Put burrs where they can be removed readily.

- Understand the real economics of burrs and your operation.

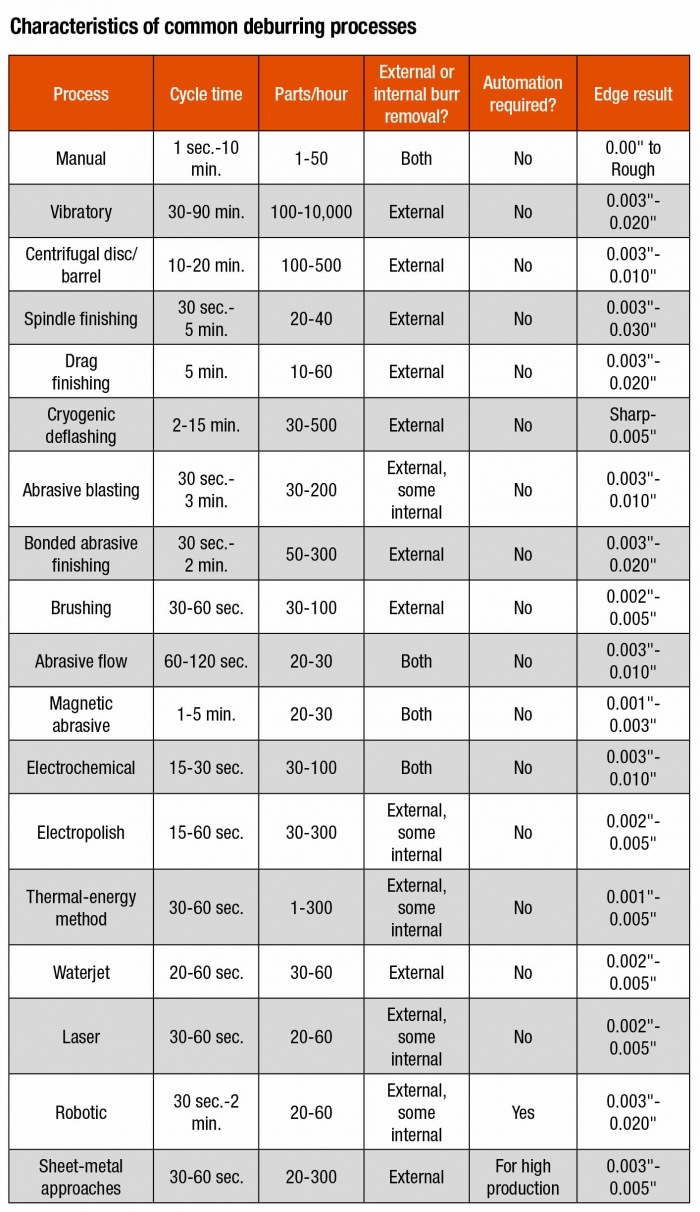

The table shown here summarizes key attributes that shops should consider when searching for the right deburring process. The table lists 18 processes, although a total of 124 processes exist. Most are variations of the processes shown. When it comes to especially challenging applications, such as deburring microscale parts and features, not all of these processes are effective, but guidance is available for those applications.

The cycle times shown generally do not include the time needed for cleaning parts after deburring or for performing other needed operations.

Deciding which process to use depends upon burr size, edge requirements, production rate and part volume, flexibility needed to deburr other parts the manufacturer produces, various part-quality requirements and economic considerations.

So, for example, the flexibility required for a job shop is entirely different from that needed for mass production of a single part, even though the processes used may be the same.

Shops should have several different deburring processes available to meet their needs, whether for a single part or a wide variety of parts. Most job shops use a mixture of manual deburring, vibratory finishing, abrasive blasting and abrasive-paper products. Highly automated shops employ robots that use the same abrasive or cutting tools as human

operators.

All deburring processes are amenable to automation at several levels, but the vast majority do not require automation, especially when deburring the low volumes of parts typically run at job shops.

A micro-abrasive blaster is used to manually deburr a copper part with numerous internal cross-drilled bores that must be completely deburred to prevent modification of airflow dynamics. Image courtesy of Comco Inc.

Vibratory finishing is readily automated by taking parts from continuous conveyors, deburring them and depositing the clean parts into a packaging, or other, line. Manual deburring can incorporate automated placement of parts. Flat sanding can be done three ways: manually, as a manual-assisted operation or a fully automated operation; all three operations deburr both sides of parts.

Cycle time depends upon the amount of edge to be deburred, burr thickness, edge tolerances, and media or tools applied. The number of parts deburred per hour depends upon the number of stations the deburring machine connects to, as well as the handling time and the cycle time.

Burrs from drilling and milling before (left) and after (right) thermal-energy deburring. Image courtesy of Vectron Deburring.

Manual, brushing, magnetic abrasive, abrasive flow, waterjet, laser and robotic processes typically deburr one part at a time, whereas mass-finishing operations, such as a vibratory process, may process 100 or more parts simultaneously.

Finishing long, cylindrical parts, such as camshafts, is performed one part at a time by placing them on the end of a rotating spindle and immersing them in a tub of vibratory media. A manufacturer typically has several of these machines running simultaneously to meet production needs. Some machines have two or four spindles.

Cryogenic deflashing and some abrasive blasting can be performed in a tub, allowing the deburring of many parts at one time. However, both processes can also deburr just one part or one feature at a time.

Electro Processes

Electrochemical deburring can readily handle several parts at one time, if the fixturing is designed to do so. Electropolish deburring—while typically associated with one or a few parts at a time—has also been automated. A continuously moving line dips parts attached to it in a weak solution, such as buffered phosphoric acid, and then a neutralizer.

Xebec ceramic fiber surface brushes deburr and finish surfaces in CNC and manual machines. Image courtesy of Deburring Technologies Inc.

The thermal-energy method exposes a small basket of parts to temperatures from 4,500° to 6,300° F (2,482° to 3,482° C) for about 2 to 3 milliseconds. The parts are surrounded by a gas that fills all of their open areas and envelops the exposed burrs. The gas is then ignited and the burrs are vaporized in a fraction of a second.

At times, burrs on sheet-metal edges can be rolled back into the parent metal. Several approaches are used on sheet metal, but ideally those edges are deburred while the part is flat, preferably while still in strip form.

To address unique burr issues, equipment manufacturers and their dealers are often able to develop innovative alternatives to common deburring processes. They can combine two processes in a cost-effective manner, or apply similar tools or supplies to save costs. But they cannot help if they are not asked.

Parts manufacturers probably are not ever going to eliminate the need for deburring. However, in almost every instance, shop personnel can reduce the cost and time required to deburr parts and produce a more-consistent product.