Faster facemilling

Faster facemilling

END USER: Continental Motors Inc., (800) 718-3411, www.genuinecontinental.aero. CHALLENGE: Boost productivity when rough and finish milling cast aluminum crankcases. SOLUTION: PCD-tipped, cartridge-type facemills. SOLUTION PROVIDER: Ingersoll Cutting Tools, (866) 690-1859, www.ingersoll-imc.com

--------------

END USER: Continental Motors Inc., (800) 718-3411, www.genuinecontinental.aero. CHALLENGE: Boost productivity when rough and finish milling cast aluminum crankcases. SOLUTION: PCD-tipped, cartridge-type facemills. SOLUTION PROVIDER: Ingersoll Cutting Tools, (866) 690-1859, www.ingersoll-imc.com

---------------

Aluminum is not generally considered a difficult-to-machine material, but aluminum castings are rife with abrasive mineral alumina, or aluminum oxide, which can quickly blunt cutting edges. This posed a challenge for Continental Motors Inc., Mobile, Ala., a manufacturer of piston-type engines. Fortunately, the company found a new cartridge-type facemill tooled with PCD-tipped inserts that dramatically improved roughing and finishing cast aluminum crankcases.

According to Continental, the facemill significantly improved flatness and finish, quadrupled the material-removal rate when roughing vs. an indexable-carbide-insert mill and doubled the mrr when finishing vs. another cartridge-type facemill with PCD-tipped inserts.

In mid-2011, Continental standardized on TEDI MILL facemills from Ingersoll Cutting Tools, Rockford, Ill., to rough and finish cast aluminum crankcases. The operations involve heavy interrupted cuts and are run continuously on a Toyoda FH630SX horizontal machining center to produce 1,750 crankcases annually at the 250-worker shop. The crankcases measure 12 " to 15 " high and 22 " to 30 " long. Two faces actually require machining: an inner face that provides the seal and an outer face for aesthetics.

TEDI MILL facemills are the only cutting tools offered as standards from Ingersoll's sister company in the IMC Group, Italian Technical Diamond Co. SRL (IT.TE.DI), Arezzo, Italy. Heretofore, the company specialized in custom PCD and PCBN boring tools. Ingersoll brought the TEDI MILL line to the U.S. market in 2011, first as a special and now as a standard.

Courtesy of Ingersoll Cutting Tools

Continental Motors quadrupled the mrr when roughing and doubled the mrr when finishing cast aluminum crankcases after switching to the TEDI MILL facemill from Ingersoll Cutting Tools.

According to Ingersoll, the cutter has a rigid cartridge seating, accepts positive-rake cartridges, delivers coolant up to 1,000 psi directly to the cutting edge and offers 2µm axial adjustment of cartridges. Instead of corner radii, the inserts have a 45° chamfer, which reduces cutting forces and resultant machining stresses by as much as 50 percent, depending on the machining parameters. In addition, the facemills are factory-balanced to run as high as 20,000 rpm and 16,000 sfm. Craig Bastian, Ingersoll's product manager for the IT.TE.DI. line, noted the tools withstood 54,000 rpm in independent tests.

Mike Brown, Continental's manufacturing engineer, was skeptical at first—until a demonstration on the shop floor showed a 6 " TEDI MILL facemill could reliably run at 10,000 rpm and a 400-ipm feed rate.

The retooling began during Brown's regular plant walk-through with Bruce Burroughs, field application engineer for Ingersoll, when the focus turned to reducing finish-milling cycle time. On large crankcases, the long cycle time and high axial cutting forces caused heat from machining to often build up to the point where the parts had to be unclamped and reclamped to relieve machining stresses. The previous cutter was a standard 6 " cartridge-type facemill tooled with 0° rake PCD inserts.

Burroughs recommended the TEDI MILL facemill. "In the TEDI MILL cutter, the cartridge is clamped to stop movement in one direction and wedged to stop movement in the other direction," he said.

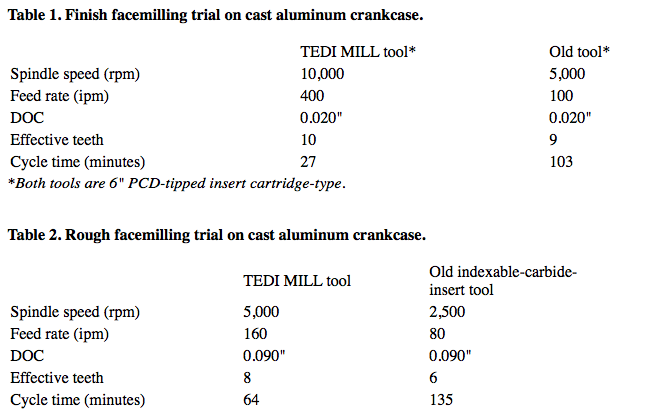

Trials were conducted on Continental's Toyoda, which validated the new tool and established machining parameters (Table 1). When going operational, Continental slightly reduced the speeds and feeds. That's because one of the machinists once worked for a machine rebuilder and had seen a lot of spindle damage. He convinced Brown to be conservative, and the operation ran without incident from day one.

Brown also asked Burroughs about an alternate 4 " facemill for roughing the crankcases, which Continental previously performed with a facemill with carbide inserts. Burroughs again recommended a TEDI MILL facemill with PCD-tipped inserts. The roughing trial, which ran on the same day as the finish-milling test, doubled throughput (Table 2). Continental immediately adopted the 4 " TEDI MILL for roughing.

"All told, the operation has kept running better and better since the retooling," Burroughs said. "The cutting area stays cooler as well, reducing part distortion due to machining stresses that can either increase reject rates or require lower material-removal rates to maintain flatness."

Based on his experience so far, Brown plans to standardize on the TEDI MILL facemills for all operations that run on milling machines with the requisite spindle speed and coolant plumbing. "TEDI MILLs are not cheap, so there's no reason to put them on machines that can't take full advantage of all their features," he said.