Better Threaders

Better Threaders

When CNC wire EDMs came on the market in the mid-'70s, feeding wire from a spool through a machine's elaborate series of rollers and guides was a tedious manual exercise. Luckily, electrical discharge machining was an exceedingly slow process back then, so replacing wire had to be done less frequently than on today's machines, which erode conductive metal 10 to 20 times faster than earlier models.

Automatic threaders for wire EDMs have evolved into practically never-miss devices

When CNC wire EDMs came on the market in the mid-'70s, feeding wire from a spool through a machine's elaborate series of rollers and guides was a tedious manual exercise. Luckily, electrical discharge machining was an exceedingly slow process back then, so replacing wire had to be done less frequently than on today's machines, which erode conductive metal 10 to 20 times faster than earlier models.

Automating the process became increasingly important as wire EDMing gained favor. As with automatic toolchangers on machining centers and turrets on CNC lathes, EDMs need automatic wire threaders (AWTs) to make end users more competitive. Thanks to decades of continuous improvement by EDM builders, AWTs are fast and accurate, boasting "in-the-hole" success rates of 90 percent or higher, and doing so while submerged, and through partially completed workpieces and Z-axis heights of 15" (381mm) or more.

Curling is Not a Sport

AWTs help machines run unattended by rethreading wire that has broken. Breakage is easy to detect, because current ceases to flow through the electrical pathway formed by the upper head, wire and lower head. Threaders also facilitate unattended operation by cutting wire when a workpiece is completed and threading the wire through a new workpiece. Knowing when a workpiece is done is a function shared by all CNCs, so telling an EDM to cut the wire and rethread at a new part location is a simple task.

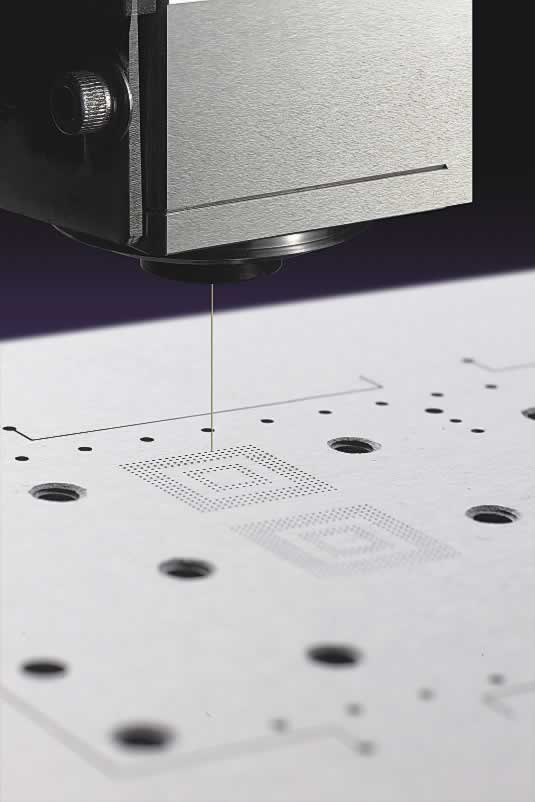

Automatic wire threading through even the smallest of holes is possible. Image courtesy Sodick.

Most EDM wire is brass and has a diameter ranging from 0.004" to 0.012" (0.102mm to 0.305mm). It's wrapped on a lunchbox-sized plastic spool and is anywhere from a few thousand yards to dozens of miles long. The challenge when threading wire is that it "remembers" it was once curled around a spool, a memory that causes it to go everywhere but where it needs to go: straight down, into the lower guide.

Many attempts have been made over the years to control wayward EDM wire, some more successful than others. Machine builder Sodick Inc., Schaumburg, Ill., long utilized a metal tube a few millimeters in diameter filled with a stream of pressurized water. When given the rethread command, the upper set of guides would open and the tube, which contained the thread, would lower 6" (152.4mm) or so. This worked well for relatively short Z-axis heights, where the tube could reach the lower guide, or in parts with a starter hole, which helps to contain the wire.

Terry Meyer, application manager at Sodick, said the tube system was replaced about 6 years ago on all of the company's water-dielectric machines and is only offered on oil-based machines sold in Japan.

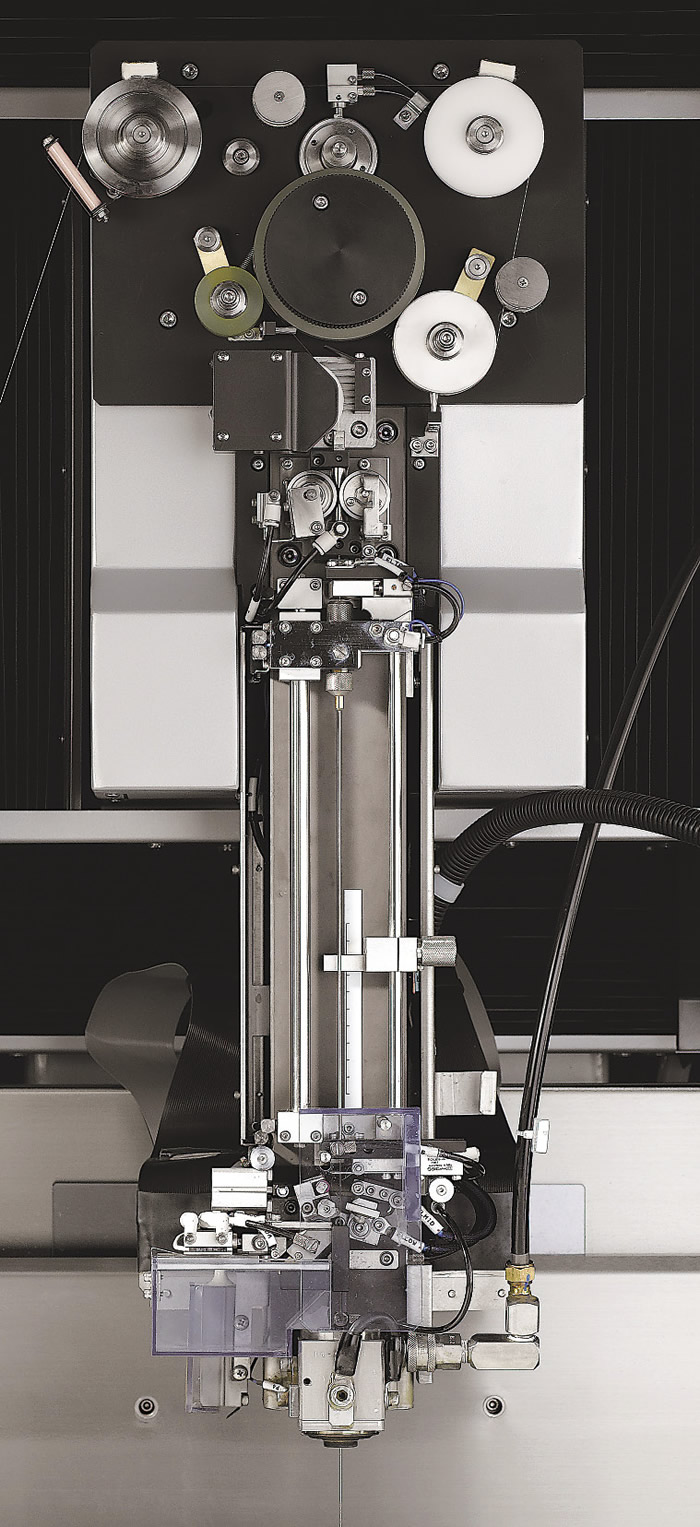

At top is the tortuous path a wire must take through an EDM. Below is Sodick's formerly used tube mechanism for threading water-dielectric EDMs. Image courtesy Sodick.

"Today, we use an annealer and waterjet-assist, a method similar to what every machine builder in the industry is using," Meyer said. An industry-standard method of wire threading, it involves application of a pressurized jet of water—approximately 30 psi (2.07 bar)—to direct the wire from the upper guide to the lower. The method requires that the wire be straight, something that's accomplished by annealing a length of wire at least equal to the distance it must traverse. For EDMs with large Z-axis travels, this means annealing the wire for 18" (457.2mm) or more.

Going Long

Mitsubishi offers such a long-travel machine. Mike Bystrek, national EDM product manager for MC Machinery Systems Inc., Wood Dale, Ill., a subsidiary of Mitsubishi Corp., said annealed lengths of up to 27" (685.8mm) are possible on some Mitsubishi models, with wire straight enough that a waterjet is often unnecessary. "Because of the annealing process, we don't have to go back to the start hole when the wire breaks. We can thread it through the workpiece from the point where the wire broke by using the kerf to guide the wire."

This capability is important, especially for shops that wire-EDM large or thick workpieces or both.

Consider an extrusion die for a 12" (304.8mm) aluminum heat sink. A starter hole would typically be drilled or EDM hole-popped near the inside edge of the extrusion profile. Suppose that 2 hours into the burn, the wire breaks. Older EDMs would require returning the wire to the start hole for rethreading, and then drive it, at low power, back through the previously burned kerf to pick up where the break occurred. Not only would this consume a lot of time, but, even worse, large workpieces tend to move during EDMing due to stresses in the metal. This causes the kerf to close up, which prevents the wire from traveling back to the break point. By threading through the kerf at a spot close to the wire break, these issues are eliminated.

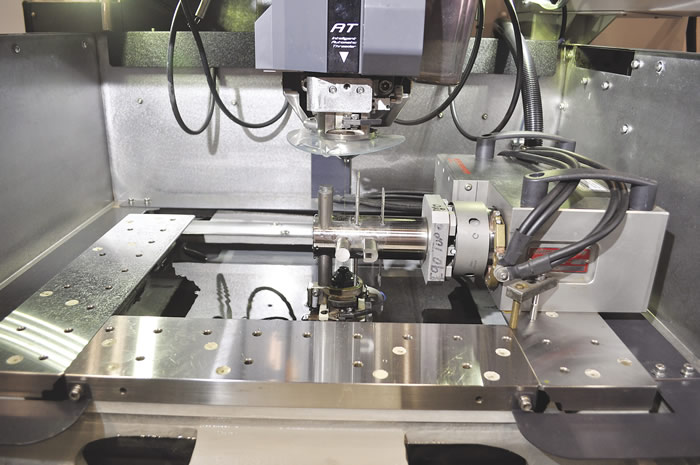

Mitsubishi's AT intelligent automatic threader reduces wire curl and rethreads through the gap if the wire breaks. Image courtesy MC Machinery Systems.

The type of wire guide also plays an important part of AWT success. Round, PCD guides with a hole just a few tenths of an inch larger than the wire diameter are the most common. Several EDM builders offer round-guide machines, as well as ones with "split," or open, guide systems. These have a V-shaped mechanism that cradles the wire from all sides, which, according to Brian Pfluger, EDM product line manager at Makino Inc., Mason, Ohio, offer greater contact area, easier threading and better guide life than round guides. "The beauty of split-guide systems is reliability. I can even have a small kink in the wire and it won't affect anything. It's like threading through a barn door."

Because of this barn-door effect, split "V" guide systems often incorporate a mechanical scissors device to cut the wire, which can leave a slight burr on the wire tip. This is not a problem with a split guide's wide opening, but will cause interference if used with a round guide. "The key driving factor with AWT performance is the end-user's application," Pfluger said. "Each wire guide system and AWT design have unique pros and cons, and each user should clearly identify and understand their own unique requirements."

Sharp as a Pencil

Annealing does more than straighten wire.

"By annealing the entire length of the wire's Z-axis travel and pulling on it slightly while applying some additional heat near the tip, the wire is made perfectly straight and separates into a nice sharp point," said Eric Ostini, product manager for GF Machining Solutions LLC, Lincolnshire, Ill. "All that's needed is to feed it straight down."

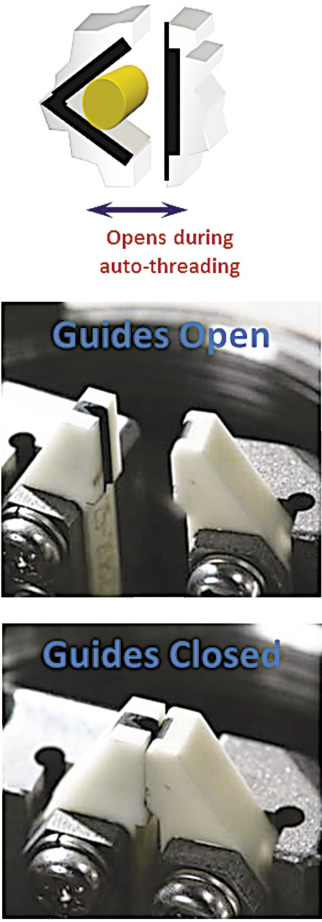

Wire kinks and scissor burrs are not a concern with split guides, which open during automatic threading. Image courtesy Makino.

An arrow-straight wire with a pointed tip is so efficient for threading that water-assist is often unnecessary—and may even cause problems. EDMing stacked workpieces, parts with internal features and parts at an angle generally create specific challenges for AWT reliability.

Ron Vogel, president of Chmer distributor EDM Network Inc., Sugar Grove, Ill., said threading through an angled workpiece is one of the more-difficult AWT activities. "We were working with a shop on a form tool that had a 15° taper," Vogel said. "The upper head was 2" away from the tool and the wire broke in the middle of the burn. We were able to thread through open air, into the kerf and down to the lower guide. It was amazing."

Anyone who's watched a rethreading operation on a modern EDM would agree: It is amazing. The secret, according to Vogel, is starting with an annealed piece of wire. Of course, each EDM builder has a proprietary technology twist aimed at increasing threading efficiency. For example, Chmer boasts fewer moving parts—five—in its threading mechanism, something Vogel claimed makes it more reliable and reduces maintenance. Sodick has a pop-up valve to sense wire buckling and automatically retracts the wire, allowing it to make repeated attempts at threading without operator intervention. GF Machining Solutions and Makino offer the choice of split and round guides, each of which has its own advantages based on the application. And Mitsubishi promotes its on-screen troubleshooting capabilities, which show the operator possible causes of threading failure.

Regardless of the logo on the machine, AWTs all do a pretty darned good job. Some are better at small-hole threading; others excel at threading tall or tapered parts. The AWT unit enables unattended machining and is the most important automated system on a wire EDM. Potential machine buyers should present their requirements to their salesperson, ask for demonstrations under varying conditions, review AWT maintenance procedures and talk to other users about their wire EDM threading experiences.

Contributors

EDM Network Inc.

(888) 289-3367

www.edmnetwork.com

GF Machining Solutions LLC

(847) 913-5300

www.gfms.com/us

Makino Inc.

(800) 552-3288

www.makino.com

MC Machinery Systems Inc.

(630) 616-5920

www.mcmachinery.com

Sodick Inc.

(888) 639-2325

www.sodick.com