A machine for dry grinding gears

A machine for dry grinding gears

Italy-based Samputensili S.p.A. unveiled a machine that eliminates the need for cutting oils when manufacturing gears, thereby reducing grinding costs. During grinding, oil-based lubricants cool the workpiece, as well as reduce friction and help evacuate chips. On the downside, however, oil use accounts for a significant amount of a grinding operation's total cost. Expensive equipment is required to supply, chill, catch and wash away oil in grinding processes. In addition, Samputensili estimates that oil-treatment equipment accounts for 75 percent of the energy consumed by a grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpi…" title="Powers a grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpi…" aria-label="Glossary: grinding machine">grinding machine.

Italy-based Samputensili S.p.A. unveiled a machine that eliminates the need for cutting oils when manufacturing gears, thereby reducing grinding costs.

During grinding, oil-based lubricants cool the workpiece, as well as reduce friction and help evacuate chips. On the downside, however, oil use accounts for a significant amount of a grinding operation's total cost. Expensive equipment is required to supply, chill, catch and wash away oil in grinding processes. In addition, Samputensili estimates that oil-treatment equipment accounts for 75 percent of the energy consumed by a grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpi…" title="Powers a grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpi…" aria-label="Glossary: grinding machine">grinding machine.

Samputensili's SG 160 Sky Grind, available from Star SU LLC, features two spindles, one for skive-hobbing and the other for grinding. With the first pass, the SG 160 removes 90 percent of the required material using its skive-hobbing tool, which does not heat the workpiece too much, explained Enrico Landi, division director of Samputensili Machine Tools.

Skive-hobbing, the hobbing of hardened gears with carbide tools, can be done without oil even in mass-production applications. But, according to Samputensili, the process has never successfully produced transmission gears, so grinding must be used for finishing.

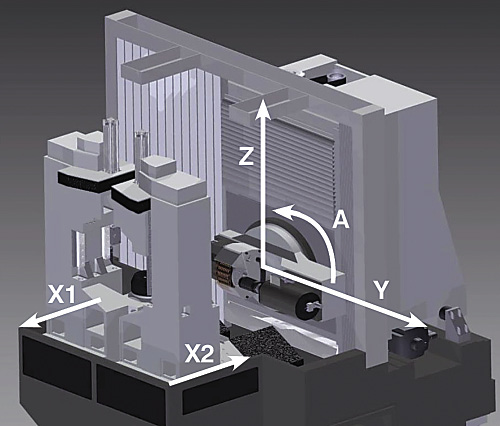

The SG 160 splits the X-axis of traditional machines into two linear slides (X1, X2), each of which supports one workpiece spindle. This allows both work spindles to be under full positioning control at all times. Driven by high-dynamic, 30-m/sec. linear motors, simultaneous repositioning of tools reportedly can be accomplished in less than 2 seconds. Image courtesy Star SU.

Samputensili's idea was to produce a machine that offers the material-removal rate of dry skive-hobbing along with the geometric accuracy and surface quality of dry finish-grinding for the mass production of automotive gears. During the second, or finishing, pass, the SG 160's grinding wheel removes the remaining material without overheating the workpiece. This provides a totally dry manufacturing process that requires no oil-related auxiliary equipment.

In addition, the SG 160 is faster than conventional dual-table grinding machines, Samputensili claims, and its cycle times for finishing gears meet automotive industry requirements. Also, the machine can shorten nonproductive part-changing times to less than 2 seconds, according to the company.

By partnering with major automotive companies in the development of the technology, Samputensili said it has already proven that the SG 160 will work as planned. The company indicated that annual savings in manufacturing planetary gears could be more than $54,000 per machine, compared to production involving conventional wet grinding.

For more information about Star SU LLC, Hoffman Estates, Ill., visit www.star-su.com or call (847) 649-1450.