Multigrit wheel benefits

Multigrit wheel benefits

The Grinding Doc offers an upbeat take on tri-grit wheels.

Dear Doc: I grind tungsten carbide-tipped saw blades and the sales guy is pushing tri-grit wheels. What's your take on these?

The Doc Replies: They're great, and here's why. Tri-grit wheels have three different grit sizes. The biggest grits on the outer edge of the cup wheel and the medium-sized grits in the middle do all the hard work. The finest grits on the inside impart a fine surface finish—but that's not the real benefit. Rather, it's how they easily wear. This produces a flat on the trailing edge of the cup wheel.

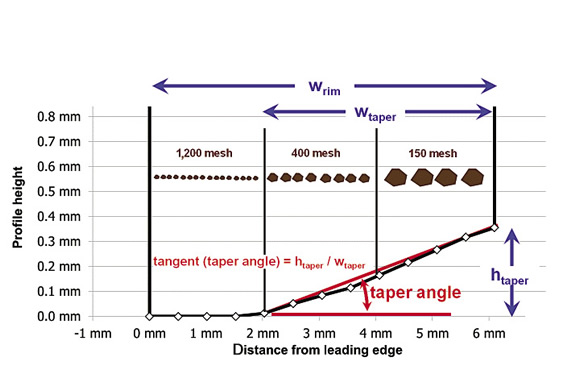

Figure 1 shows a measured profile of a worn cup wheel at a company I visited that grinds carbide-tipped endmills. You can see that the fine, 1,200-mesh grits wore away and created a flat. That flat, along with the grit size, will impart a fine surface finish. The larger 150-mesh and 400-mesh grits remove most of the material.

In contrast, with only a single grit size, the taper wears more evenly and eventually you are grinding with a point at the inner rim of the wheel—i.e., without a flat—and this produces a poor surface finish. That's why a tri-grit wheel can work so well.

Dear Doc: I grind cermet-tipped saw blades with cup wheels and notice that the surface finish eventually deteriorates after truing. Somebody mentioned dressing a taper. How does this work?

The Doc Replies: Cup wheels are horrifically maddening. After truing a cup wheel flat, all the grinding occurs at the leading edge. A taper slowly develops and the grinding shifts from the front of the wheel to the bottom. That's fine, but eventually this taper nearly turns into a point and surface finish deteriorates while grinding temperatures rise.

Some companies true a taper into the wheel, but that's not ideal either. The best situation is to true a taper and a flat (Figure 1). The taper does the work while the flat imparts a good surface finish.

Figure 1. The measured profile of a worn cup wheel. Image courtesy J. Badger.

What taper angle should you true? For a 5mm-wide rim, use 1.5mm for the flat width (wflat). This leaves 3.5mm for the taper width (wtaper). The taper height (htaper) is the DOC. Therefore, the equation for the taper angle is tangent (taper angle) = htaper ÷ wtaper. Let's say you're taking a 0.5mm DOC; then the tangent (taper angle) is 0.5 ÷ 3.5 and the taper angle is 8.1°.

Keep in mind, this is for single-direction grinding. For two-direction grinding, you'll have two tapers and a flat in the middle. CTE

About the author: Dr. Jeffrey Badger is an independent grinding expert. The Doc will be giving his 3-day Carbide Master Grinder Clinic in Biberach, Germany, this fall. www.TheGrindingDoc.com